Improvement process of pouring control method for wind power nodular cast iron hub

A nodular cast iron and control method technology, which is applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of easy adhesion of thermal insulation covering agent and difficulty in cleaning, and achieve simplification of pouring slag blocking action, reduction of work intensity and saving The effect of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

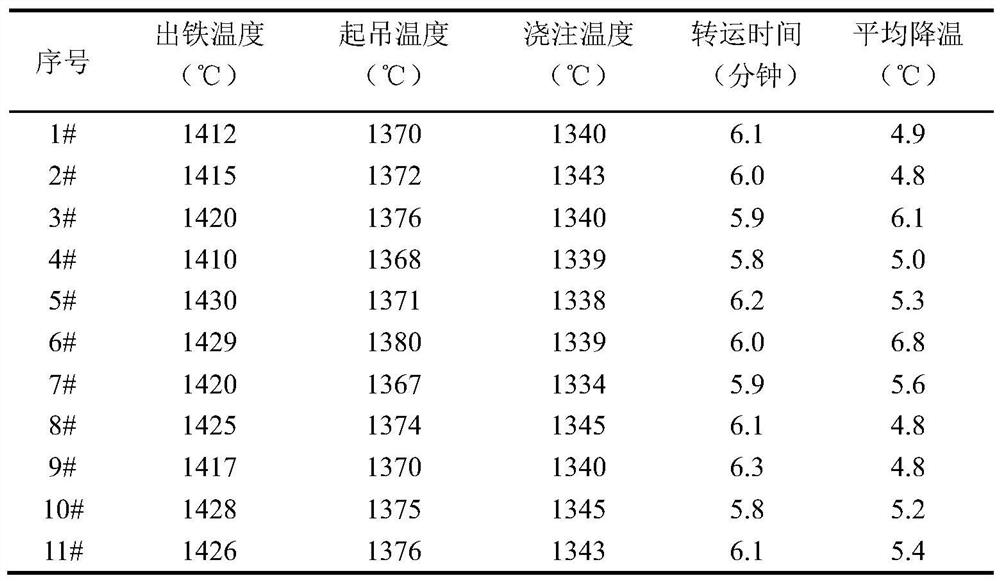

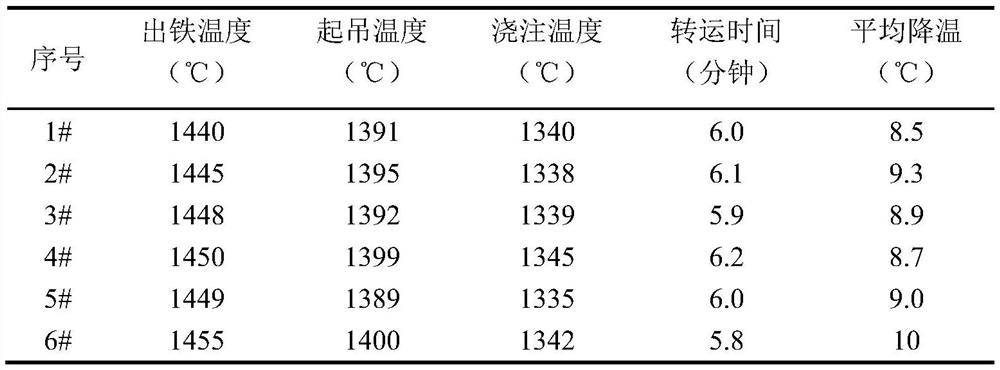

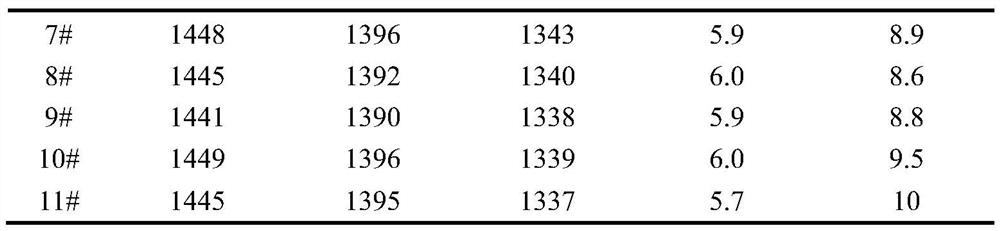

Embodiment 1

[0038] This embodiment is a smelting and pouring process for wind power ductile iron 2MW hub slag prevention and molten iron temperature control. The 2MW hub pouring weight is 14300㎏, and the ladle used is 15 tons of molten iron. , the specific manufacturing method is: one, ladle maintenance, the slag hanging on the wall of the spheroidizing treatment bag to be used is cleaned up, and the wall of the ladle is repaired and smoothed. 2. Remove slag in the electric furnace. Before tapping the electric furnace, remove the scum on the surface of the furnace with a slag collector. 3. Reduce the adding ratio of the nodulizer, and add the nodulizer according to 1% to reduce the amount of scum after magnesium explosion and the formation of molten iron filling magnesium slag. 4. Remove the slag after spheroidization, and use a slag collector to clean up the scum generated during the magnesium explosion process. 5. Cover the mixed thermal insulation covering agent. Cover the surface of ...

Embodiment 2~3

[0044] The difference between Examples 2-3 and Example 1 is that the mass ratios of the slag collector and the heat preservation covering agent of the mixed heat preservation agent in step 5 are 1:1.2 and 1:0.8 respectively, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com