A grooved drum pattern mold and a method for preparing artificial stone with slender lines

An artificial stone and roller technology, which is applied in the field of grooved roller pattern molds and the preparation of artificial stone with slender lines, can solve the problems of lack of natural marble color and aesthetic feeling, unstable texture state, and unstable product texture, etc. Eliminate texture displacement and instability, fast texture production speed, clear and accurate product texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

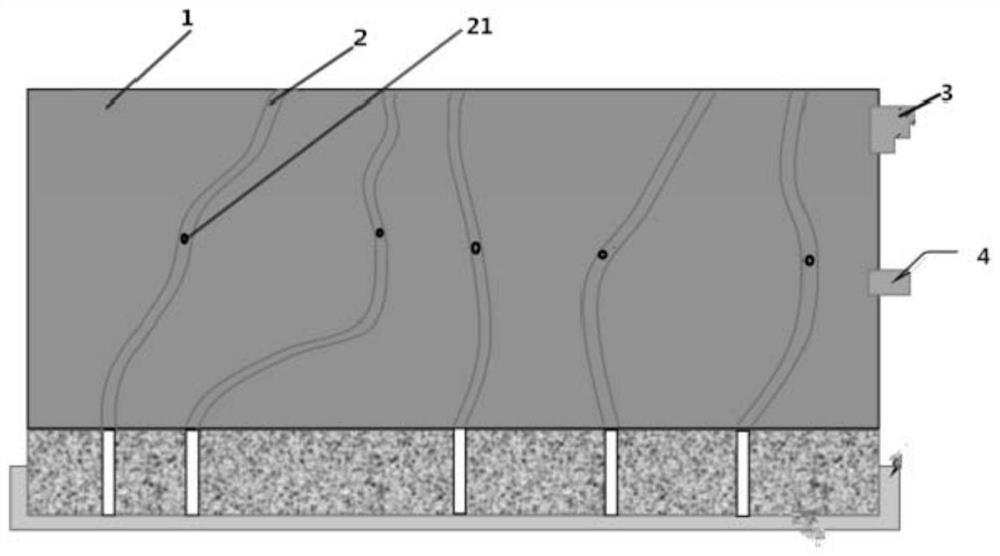

[0032] 1. Preparation of grooved drum pattern mold

[0033] 1. First prepare a 316 stainless steel hollow cylinder 1 with a diameter of 250mm, a length of 1600mm and a wall thickness of 5mm. A powder adding port 3 and a compressed air inlet 4 are provided on one of the bottom surfaces of the hollow cylinder 1 .

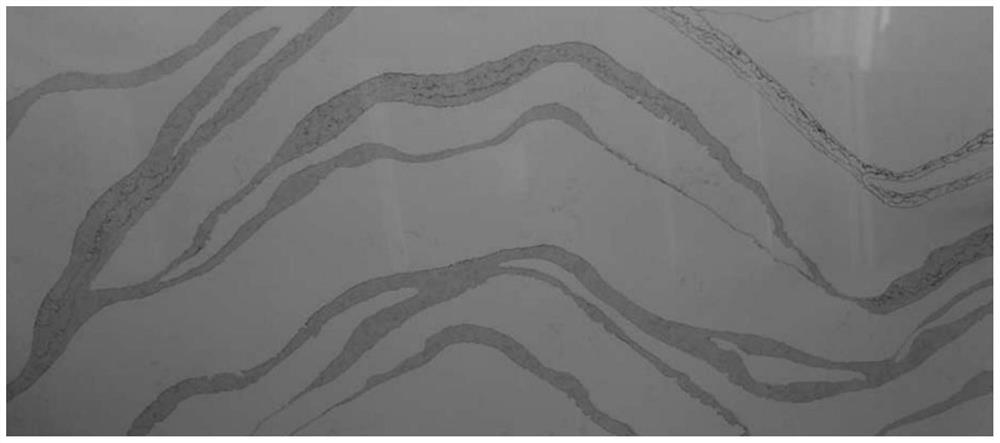

[0034] 2. Press as figure 1 As shown in the marble slender pattern, use the computer to spray the slender pattern on 3200*1600mm paper, and then paste the pattern drawing on the surface of the hollow cylinder 1, according to the pattern on the pattern drawing on the side of the hollow cylinder 1 The elongated groove 2 of 316 stainless steel is welded, the width of the elongated groove 2 is 2mm, and the height is 10mm; each elongated groove 2 is provided with an air hole 21 on both sides in the height direction, and each air hole 21 The diameter of each air hole 21 is 1 mm, which is arranged at the height corresponding to the center of the elongated groove 2 . The e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com