Modified magnesium oxysulfide cement and preparation method thereof

A technology of magnesium oxysulfate cement and magnesium oxysulfate water, which is applied in the field of building materials, can solve the problems of high cost of modifiers, rising price of fly ash, etc., and achieves reduction of cement porosity, reduction of raw material dosage, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

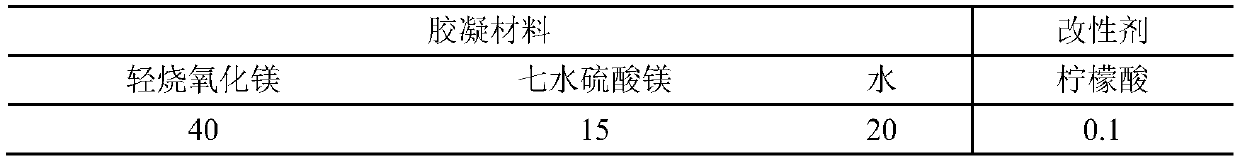

[0032] The content of active magnesium oxide in light-burned magnesia is 63%; magnesium sulfate heptahydrate is analytically pure magnesium sulfate heptahydrate, with a purity of ≥99.8%; the modifier is analytically pure citric acid, with a purity of ≥99.8%;

[0033] The ratio of modified magnesium oxysulfate cement is shown in the following table: (unit / mass part)

[0034]

[0035] Prepare modified magnesium oxysulfide cement according to the ratio of raw materials in the above table, including the following steps:

[0036] Raw materials are weighed according to proportioning, 40 mass parts of light-burned magnesium oxide powder, 15 mass parts of magnesium sulfate heptahydrate, 20 mass parts of water and 0.1 mass part of citric acid; magnesium sulfate heptahydrate is dissolved in water to prepare magnesium sulfate solution; citric acid is added to the obtained magnesium sulfate solution; the lightly burned magnesium oxide and the magnesium sulfate solution added with citri...

Embodiment 2

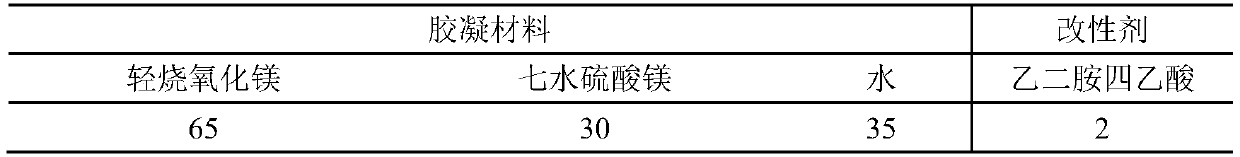

[0038] The content of active magnesium oxide in light-burned magnesia is 60%; magnesium sulfate heptahydrate is analytically pure magnesium sulfate heptahydrate, with a purity of ≥99.8%; the modifier is analytically pure ethylenediaminetetraacetic acid, with a purity of ≥99.8%;

[0039] The ratio of modified magnesium oxysulfate cement is shown in the following table: (unit / mass part)

[0040]

[0041] Prepare modified magnesium oxysulfide cement according to the ratio of raw materials in the above table, including the following steps:

[0042] Weigh the raw materials according to the ratio, 65 parts by mass of light-burned magnesium oxide powder, 30 parts by mass of magnesium sulfate heptahydrate, 35 parts by mass of water and 2 parts by mass of ethylenediaminetetraacetic acid; dissolve magnesium sulfate heptahydrate in water to prepare into a magnesium sulfate solution; add ethylenediaminetetraacetic acid to the resulting magnesium sulfate solution; lightly burned magnesi...

Embodiment 3

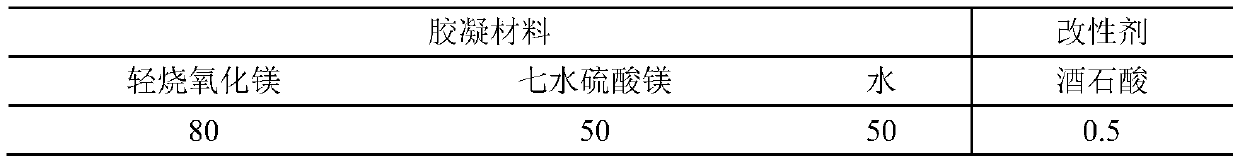

[0044] The content of active magnesium oxide in light-burned magnesia is 61%; magnesium sulfate heptahydrate is analytically pure magnesium sulfate heptahydrate, with a purity of ≥99.8%; the modifier is analytically pure tartaric acid, with a purity of ≥99.8%;

[0045] The ratio of modified magnesium oxysulfate cement is shown in the following table: (unit / mass part)

[0046]

[0047] Prepare modified magnesium oxysulfide cement according to the ratio of raw materials in the above table, including the following steps:

[0048] Raw materials are weighed according to proportioning, 70 mass parts of light-burned magnesium oxide powder, 28 mass parts of magnesium sulfate heptahydrate, 30 mass parts of water and 0.5 mass parts of tartaric acid; magnesium sulfate heptahydrate is dissolved in water and formulated into magnesium sulfate solution Add tartaric acid to the obtained magnesium sulfate solution; lightly burned magnesium oxide and magnesium sulfate solution added with tarta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com