Method for preparing borate bond exchange based self-repairing light-cured reconstructable system

A borate bond and photocuring technology, which is applied in the field of preparation of self-healing photocuring reconfigurable systems, can solve the problems of complex synthesis steps and unsuitability for industrial production, and achieve fast curing speed, low solution efficiency, and environmental protection The effect of pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

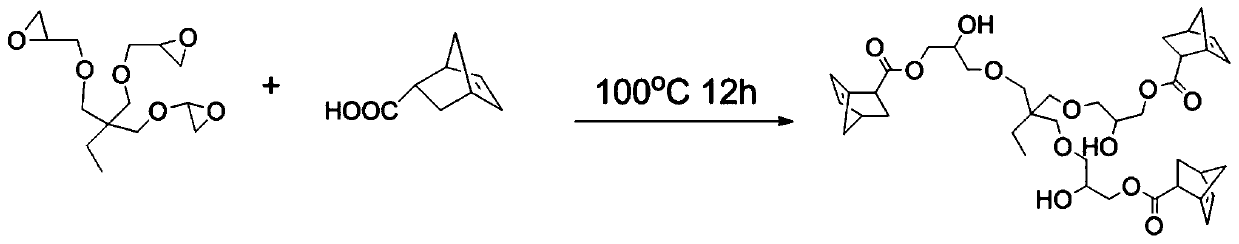

[0035] The preparation method of the self-healing light-curing reconfigurable system based on borate bond exchange is characterized in that it has the following classic steps:

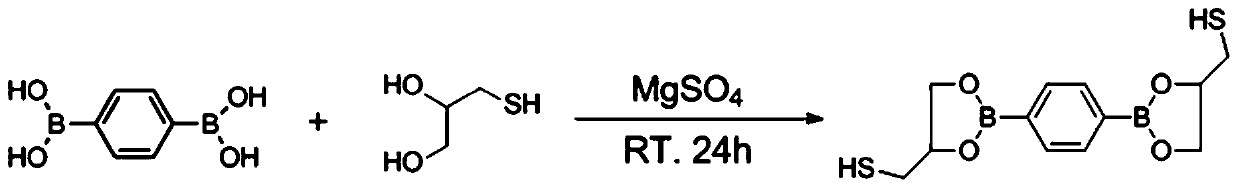

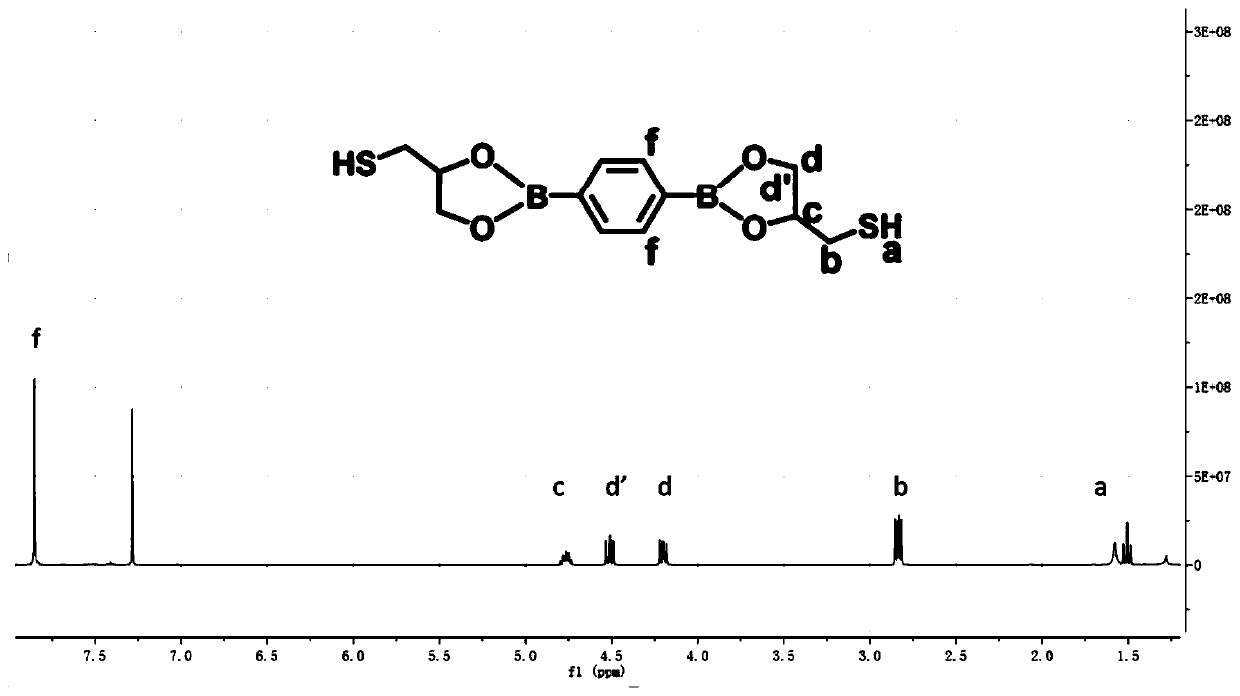

[0036] The synthetic steps of borate-containing dimercapto monomer (monomer 2):

[0037] Step a1: sequentially add p-diphenylboronic acid, anhydrous benign solvent and anhydrous magnesium sulfate to a container equipped with a magnetic stirrer, and slowly add 1-mercaptoglycerol to the system under rapid stirring, and react at room temperature for 24 hours. The molar ratio of p-diphenylboronic acid to 1-mercaptoglycerol is 1:1-1.2, the molar ratio of p-diphenylboronic acid to anhydrous magnesium sulfate is 1:5-10, and the mass ratio of p-diphenylboronic acid monomer to anhydrous benign For 1:6-10.

[0038]Step b1: after the completion of the reaction is confirmed by TLC, the insoluble inorganic salts are filtered off with suction, the filtrate is collected, and rotary evaporated, the temperature is con...

Embodiment 1a

[0050] Example 1a: 3.0g of p-diphenylboronic acid, 50ml of anhydrous tetrahydrofuran and 5.0g of anhydrous magnesium sulfate were sequentially added to a container equipped with a magnetic stirrer, and 4.01g of 1-mercaptoglycerol was slowly added to the system under rapid stirring , 24h at room temperature. After the completion of the reaction was confirmed by TLC, the insoluble inorganic salts were filtered off, the filtrate was collected, and rotovaped with the temperature controlled at 40-50°C. After the solvent was completely removed, 100 mL of deionized water was added to the system, extracted 3 times with dichloromethane, washed with saturated brine for 2-3 times, and dried with anhydrous sodium sulfate. After filtration, the solvent was removed by rotary evaporation to obtain crude product. Purify the crude product by column chromatography, the eluent is (petroleum ether: ethyl acetate = 3:1 / v:v), after collection and concentration, 5.01g of white solid is obtained, wh...

Embodiment 1b

[0051] Example 1b: 3.0g of p-diphenylboronic acid, 80ml of anhydrous dichloromethane and 5.0g of anhydrous magnesium sulfate were successively added to a container equipped with a magnetic stirrer, and 4.01g of 1- Mercaptoglycerol, react at room temperature for 24h. After the completion of the reaction was confirmed by TLC, the insoluble inorganic salts were filtered off, the filtrate was collected, and rotovaped with the temperature controlled at 40-50°C. After the solvent was completely removed, 100 mL of deionized water was added to the system, extracted 3 times with dichloromethane, washed with saturated brine for 2-3 times, and dried with anhydrous sodium sulfate. After filtration, the solvent was removed by rotary evaporation to obtain crude product. Purify the crude product by column chromatography, the eluent is (petroleum ether: ethyl acetate = 3:1 / v:v), after collection and concentration, 4.83g of white solid is obtained, which is the borate bond dimercapto monomer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com