Preparation method of aerogel film lubricant

A technology of airgel and anti-blocking agent, which is applied in the field of preparation of airgel film anti-opening agent, can solve the problems of affecting the opening performance, not easy to disperse, and low affinity, so as to improve the anti-oxidation ability, improve the affinity, Improve the effect of antistatic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

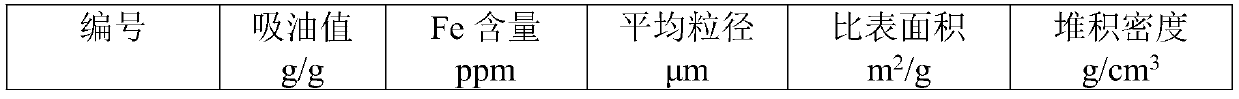

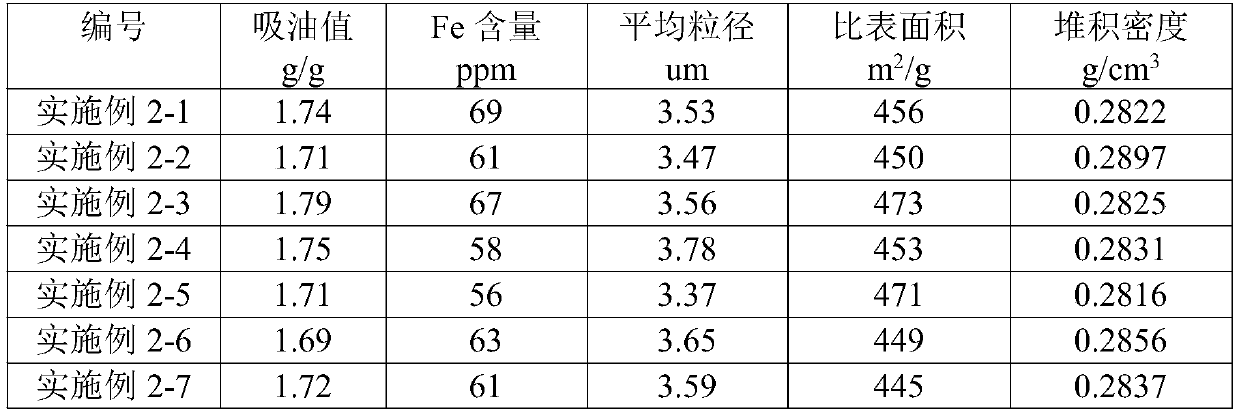

Embodiment 1

[0038] Preparation of Airgel Film Opening Agent

[0039]At a temperature of 30°C, inject 20L of bottom water and 10L of water glass solution with a silicon dioxide concentration of 10wt% into the stirred reaction vessel, add 4L of sulfuric acid with a concentration of 10wt% after 30 minutes, and react until the final pH value is 6 , stop stirring, and gel reaction for 1 hour. After the gel was completed, it was stirred for 2 hours, and the temperature was raised to 90° C. while stirring. After the temperature reaches, add a small amount of sodium hydroxide to adjust the pH value to 10, and simultaneously add 5 L of sulfuric acid and 12 L of water glass solution with a concentration of 10 wt % in parallel, the pH value in parallel flow is 10 and the time in parallel flow is 2 hours. After the parallel flow is completed, the temperature is adjusted to 95° C., and KH161 (phenyltrimethoxysilane) with a silicon dioxide content of 0.5% is added, and aged for 4 hours. After aging, ...

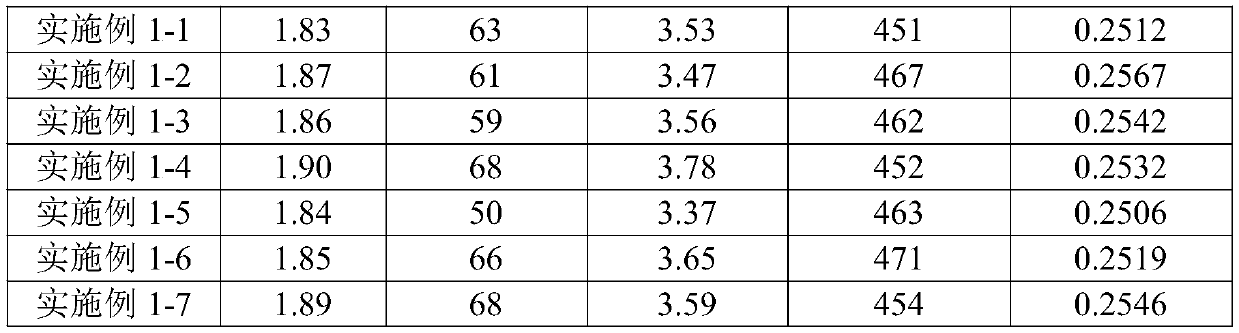

Embodiment 2

[0044] Preparation of Airgel Film Opening Agent

[0045] At a temperature of 50°C, inject 20L of bottom water and 7L of water glass solution with a silicon dioxide concentration of 15wt% into the stirred reaction vessel, add 2.5L of sulfuric acid with a concentration of 20wt% after 30 minutes, and react until the terminal pH is 8. Stop stirring, and the gel reacts for 1.5 hours. After the gel was completed, it was stirred for 1 hour, and the temperature was raised to 80° C. while stirring. After the temperature is reached, add a small amount of sodium hydroxide to adjust the pH value to 9, and simultaneously add 2.3 L of sulfuric acid and 7 L of water glass solution with a concentration of 15 wt % in parallel, and the pH value in parallel flow is 9 and the time in parallel flow is 1 hour. After the parallel flow is completed, the temperature is adjusted to 90° C., and KH162 (phenyltriethoxysilane) with a silicon dioxide content of 0.5% is added for aging for 3 hours. After a...

Embodiment 3

[0049] Preparation of Airgel Film Opening Agent

[0050] At a temperature of 40°C, inject 20L of bottom water and 20L of water glass solution with a silica concentration of 5wt% into the stirred reaction vessel, add 1.2L of sulfuric acid with a concentration of 30wt% after 30 minutes, and react until the terminal pH is 7. Stop stirring, and the gel reacts for 2 hours. After the gel was completed, it was stirred for 1.5 hours, and the temperature was raised to 70° C. while stirring. After the temperature is reached, add a small amount of sodium hydroxide to adjust the pH value to 8, and simultaneously add 1 L of sulfuric acid and 20 L of water glass solution with a concentration of 30 wt % in parallel, and the pH value in parallel flow is 8 and the time in parallel flow is 1.5 hours. After the parallel flow is completed, the temperature is adjusted to 85° C., KH163 (diphenyldimethoxysilane) with a silica content of 0.5% is added, and aged for 2 hours. After aging, sulfuric ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com