A method for extracting peony seed oil and peony protein peptide by enzymatic hydrolysis

A technology of peony seed oil and peony seeds, which is applied in the field of food and peptide or protein preparation, can solve the problems of long microbial fermentation time, poor combination effect, cumbersome procedures, etc., and achieve improved enzymatic hydrolysis efficiency, product activity, and transparent color Bright, good-tasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

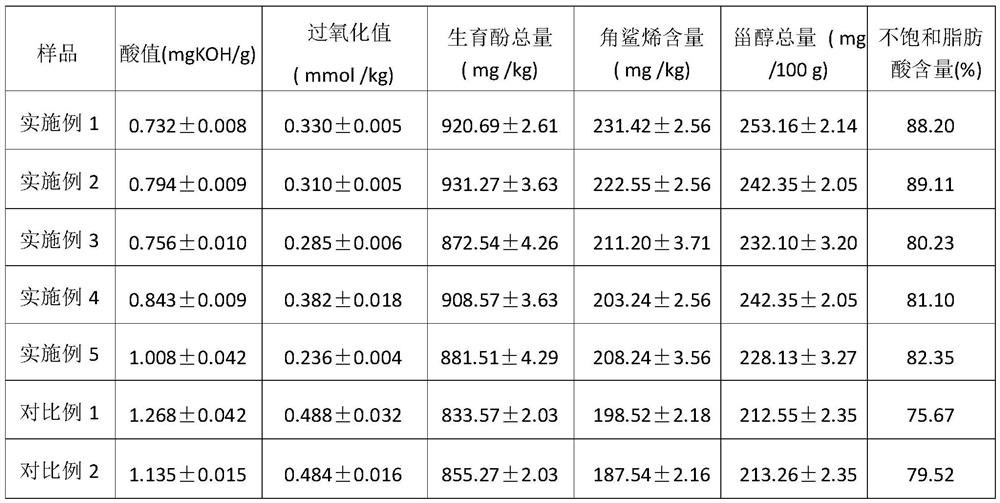

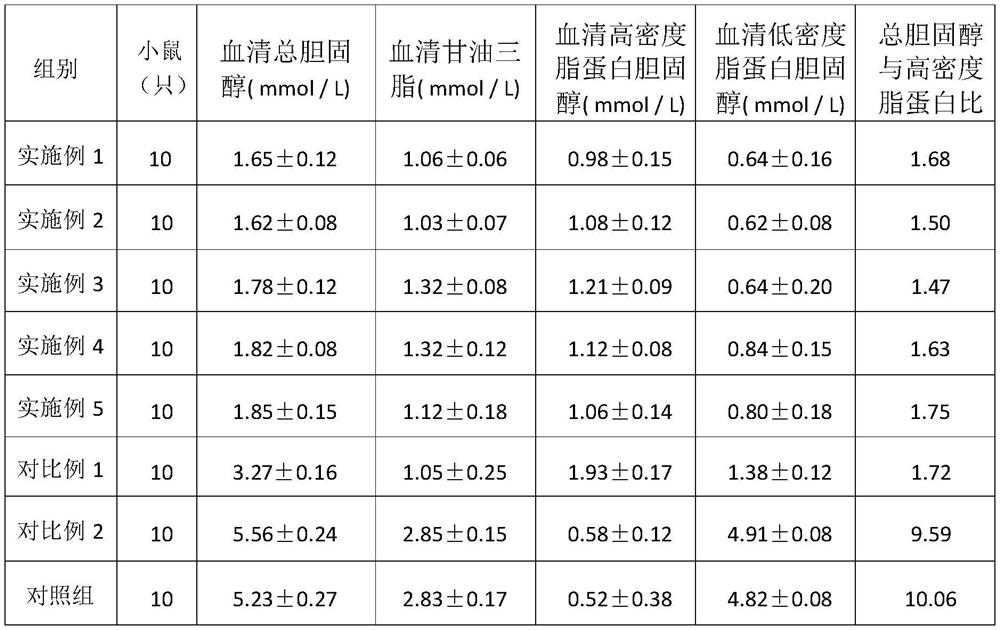

Examples

Embodiment 1

[0029] A method for extracting peony seed oil and peony protein peptide by a water enzymatic hydrolysis method, comprising the following steps:

[0030] (1) Preparation of peony seed kernel powder: the peony seed kernels are collected after the peony seeds are broken, pulverized, passed through a 40-mesh sieve, and treated with a microwave of 8kW power for 30 min under vacuum conditions of 50° C. to obtain peony seed kernels. pink.

[0031] (2) Wall breaking: the peony seed kernel powder obtained in step (1) is subjected to wall breaking with an ultrafine airflow pulverizing classifier, and the wall breaking time is 25min.

[0032] (3) Ultrasonic enzymolysis: adding water to the broken peony seed kernel powder obtained in step (2), the amount of water added is 6 times the weight of the peony seed kernel powder, and then adding alkaline protease, the amount of alkaline protease added It is 0.026% of the weight of peony seed kernel powder, and the protease is Alcalas 2.4L. Ult...

Embodiment 2

[0038] A method for extracting peony seed oil and peony protein peptide by a water enzymatic hydrolysis method, comprising the following steps:

[0039] (1) Preparation of peony seed kernel powder: the peony seed kernels are collected after the peony seeds are broken, pulverized, passed through a 40-mesh sieve, and treated with microwaves with a power of 10 kW for 30 min under vacuum conditions of 40° C. to obtain peony seed kernels. pink.

[0040] (2) Wall breaking: the peony seed kernel powder obtained in step (1) is subjected to wall breaking with an ultrafine airflow pulverizing classifier, and the wall breaking time is 30min.

[0041] (3) Ultrasonic enzymolysis: adding water to the broken peony seed kernel powder obtained in step (2), the amount of water added is 7 times the weight of the peony seed kernel powder, and then adding alkaline protease, the amount of alkaline protease added It is 0.03% of the weight of peony seed kernel powder, and the protease is Ns37071. U...

Embodiment 3

[0047] A method for extracting peony seed oil and peony protein peptide by a water enzymatic hydrolysis method, comprising the following steps:

[0048] (1) Preparation of peony seed kernel powder: the peony seed kernels are collected after the peony seeds are broken, pulverized, passed through a 40-mesh sieve, and treated with a microwave of 8kW power for 30 min under vacuum conditions of 30° C. to obtain peony seed kernels. pink.

[0049] (2) Wall breaking: the peony seed kernel powder obtained in step (1) is subjected to wall breaking with an ultrafine airflow pulverizing classifier, and the wall breaking time is 20min.

[0050] (3) Ultrasonic enzymolysis: adding water to the broken peony seed kernel powder obtained in step (2), the amount of water added is 8 times the weight of the peony seed kernel powder, and then adding alkaline protease, the amount of alkaline protease added It is 0.03% of the weight of peony seed kernel powder, and the protease is 0.02% of Ns37071 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com