Shift-fork-type anti-silting recharge system applied to river channel

A river channel and fork technology, applied in the field of self-seepage reverse filtration and recharge system, can solve the problems of silt blockage, loss of reverse filtration function, and groundwater pollution at the bottom of the recharge pond, so as to prevent silt settlement, facilitate silt prevention, and facilitate The effect of refilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

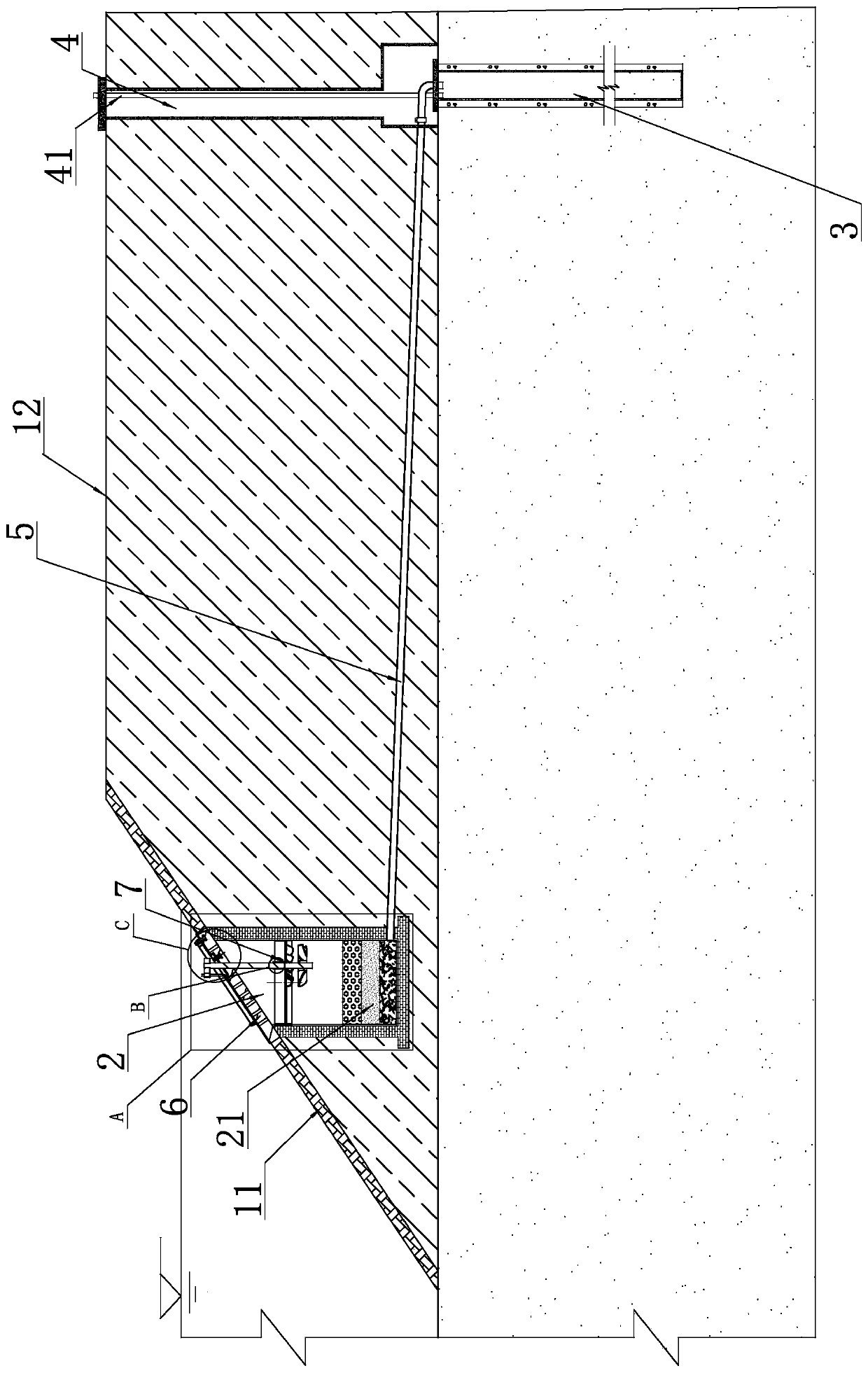

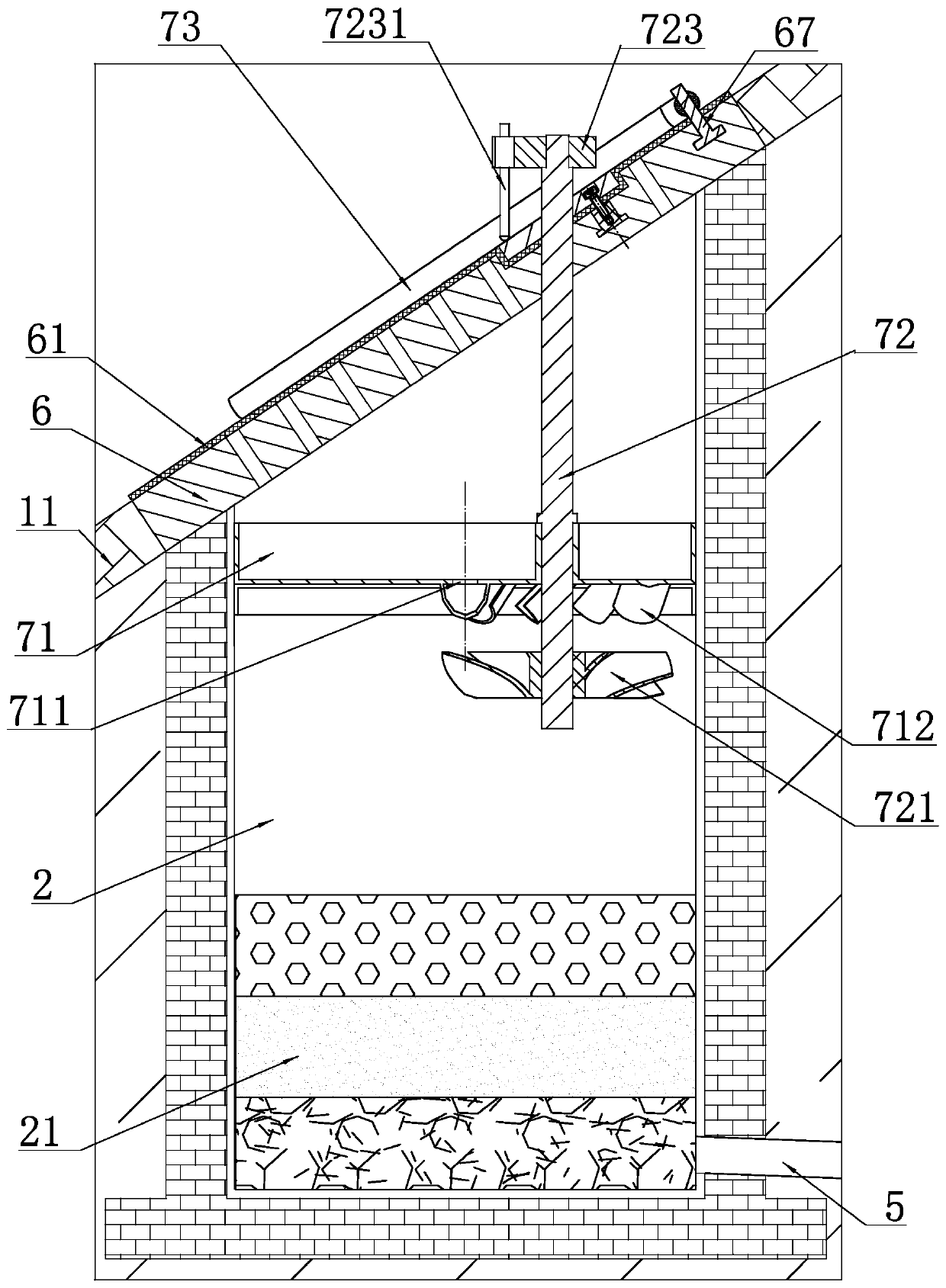

[0047] Such as figure 1 As shown, a fork type anti-silting recharge system applied to the river includes a recharge tank 2 and a recharge well 3, wherein the recharge tank 2 is set on the river slope protection 11, and the recharge well 3 is set Below the slope top 12 , a recharge pipeline 5 is arranged between the recharge tank 2 and the recharge well 3 .

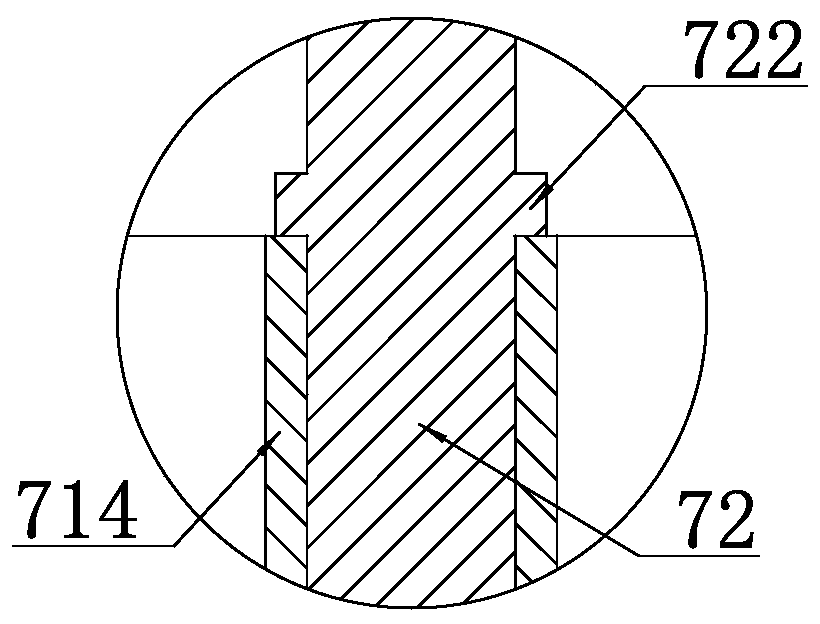

[0048] Such as figure 2 and Figure 6 As shown, the top of the recharge well 3 is provided with a first cover plate 31 for covering the wellhead of the recharge well 3, and one end of the recharge pipeline 5 communicates with the lower part of the recharge tank 2, and the The other end of the reinjection pipeline 5 passes through the first cover plate 31 and communicates with the reinjection well 3 . The reverse filter material 21 for filtering the river water is arranged in the recharge pond 2 . A permeable cover plate 6 for covering the mouth of the recharge tank 2 is arranged above the recharge tank 2. Preferably, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com