Oil shale in-situ exploitation downhole ignition and heating device and heating method

An in-situ mining and heating device technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of in-situ conversion technology of oil shale, inconvenient installation and operation of equipment and instruments, and low heating efficiency, etc. problems, to achieve the effects of improving combustion efficiency and energy utilization, reducing pipeline transportation loss, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

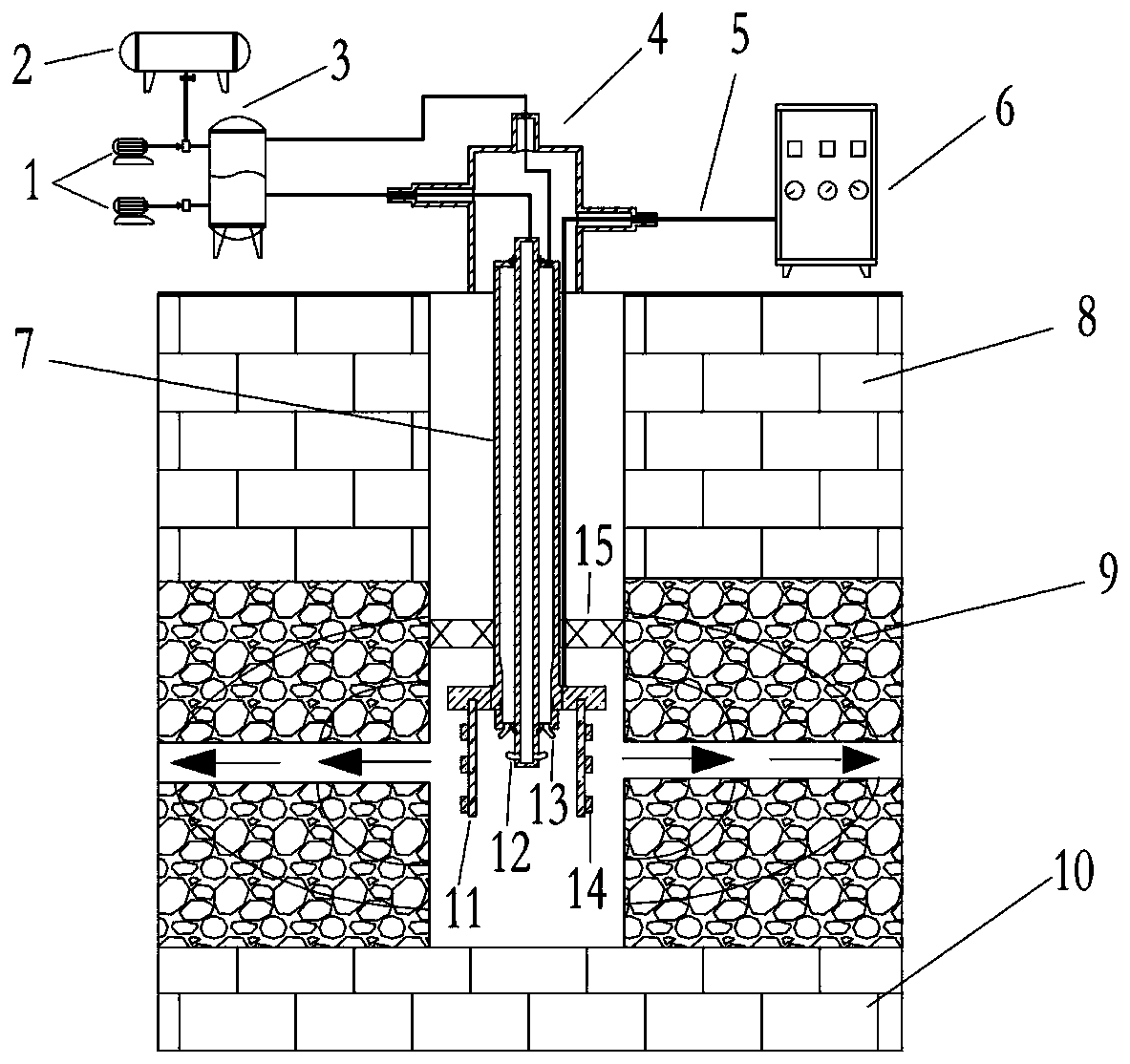

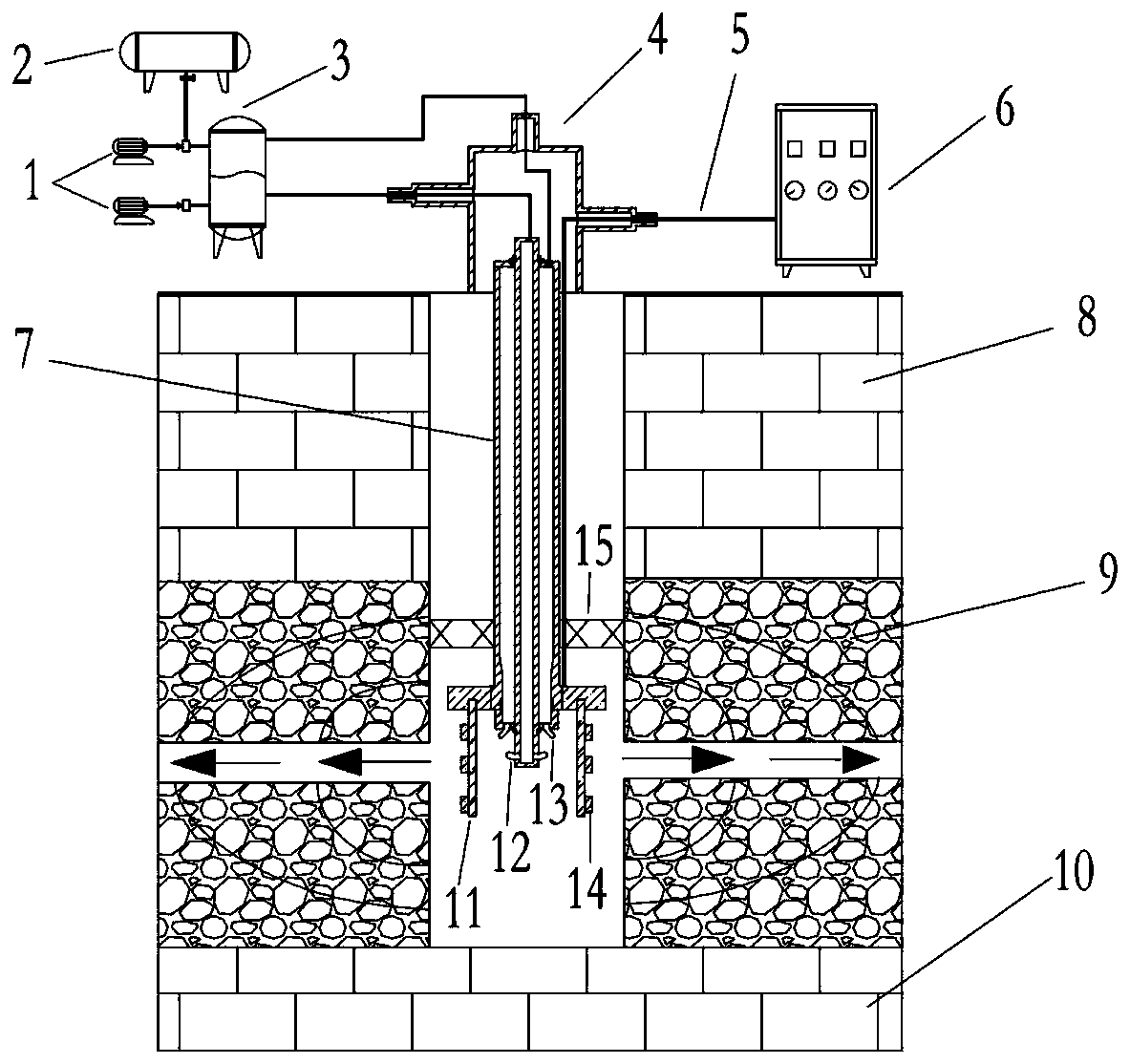

[0028] see figure 1 As shown, the oil shale mining well is an overlying rock layer 8 and an oil shale layer from top to bottom, and the oil shale layer includes a first oil shale layer 9 and a second oil shale layer 10;

[0029] see figure 1 As shown, a downhole ignition and heating device for oil shale in-situ mining, including a motor pump 1, a fuel tank 2, a pressure balance device 3, a wellhead packer 4, a signal cable 5, a heating controller 6, and a double-walled drill pipe 7 , heating rod 11, air nozzle 12, swirl nozzle 13, flame detector 14 and downhole packer 15; motor pump 1 includes air pump and oil pump;

[0030] The motor pump 1, the fuel tank 2 and the pressure balance device 3 form a high-pressure oil and gas injection system;

[0031] The heating controller 6 and the flame detector 14 form an ignition heating measurement and control system;

[0032] The double-walled drill pipe 7, the downhole packer 15 and the signal cable 5 constitute an in-hole pipe strin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com