Passivated solar cell with printed metal electrodes and preparation method thereof

A solar cell and metal electrode technology, which is applied in the field of solar cells, can solve the problems of not considering the recombination of metal and semiconductor contact areas and affecting the efficiency of crystalline silicon solar cells, so as to reduce metal contact recombination and resistance loss, improve open circuit voltage and Conversion efficiency, effect of increasing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

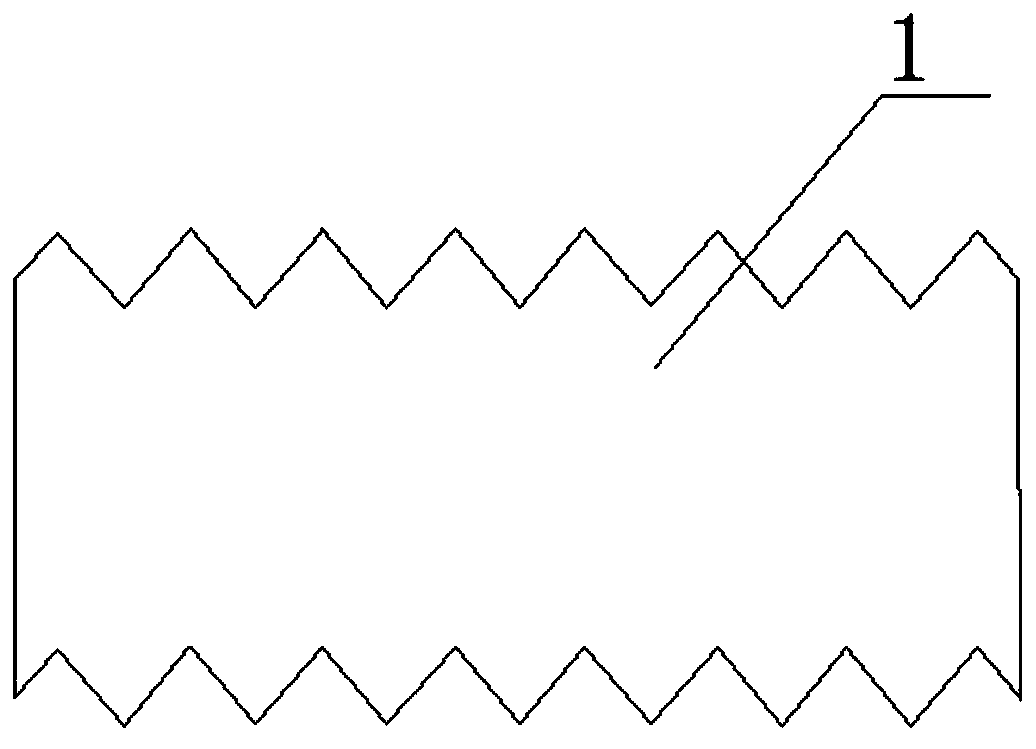

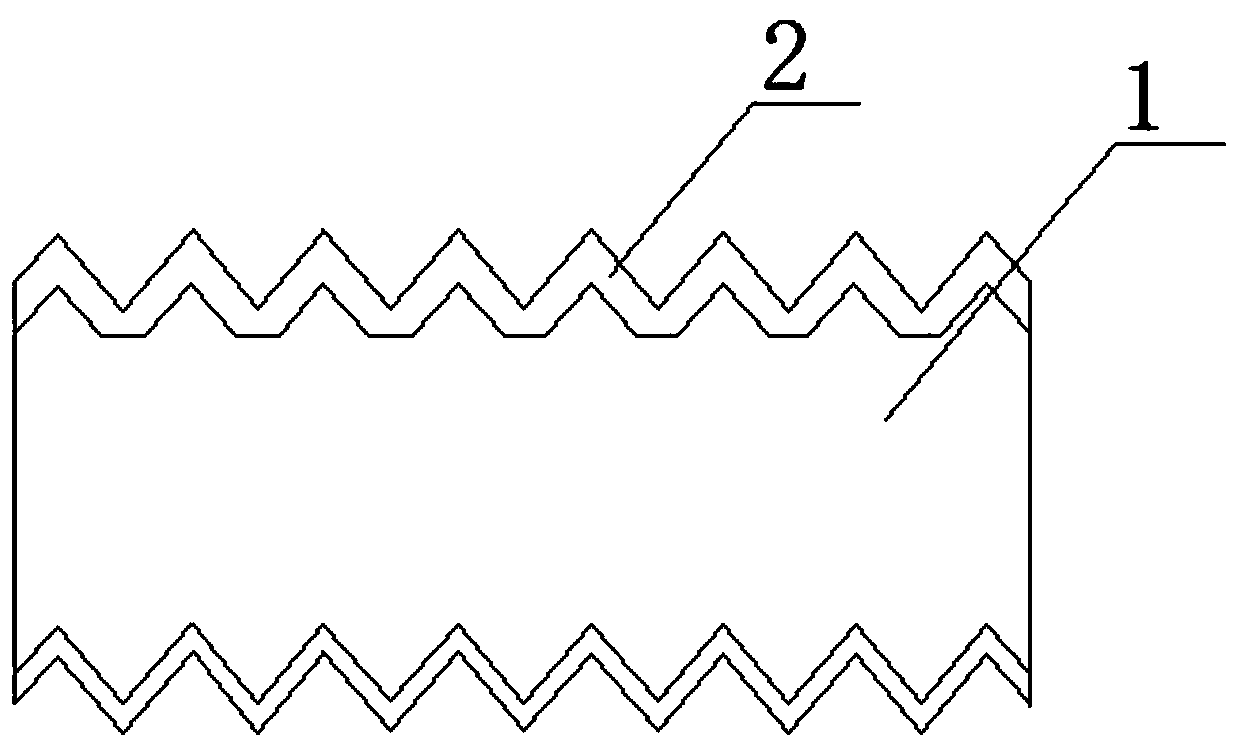

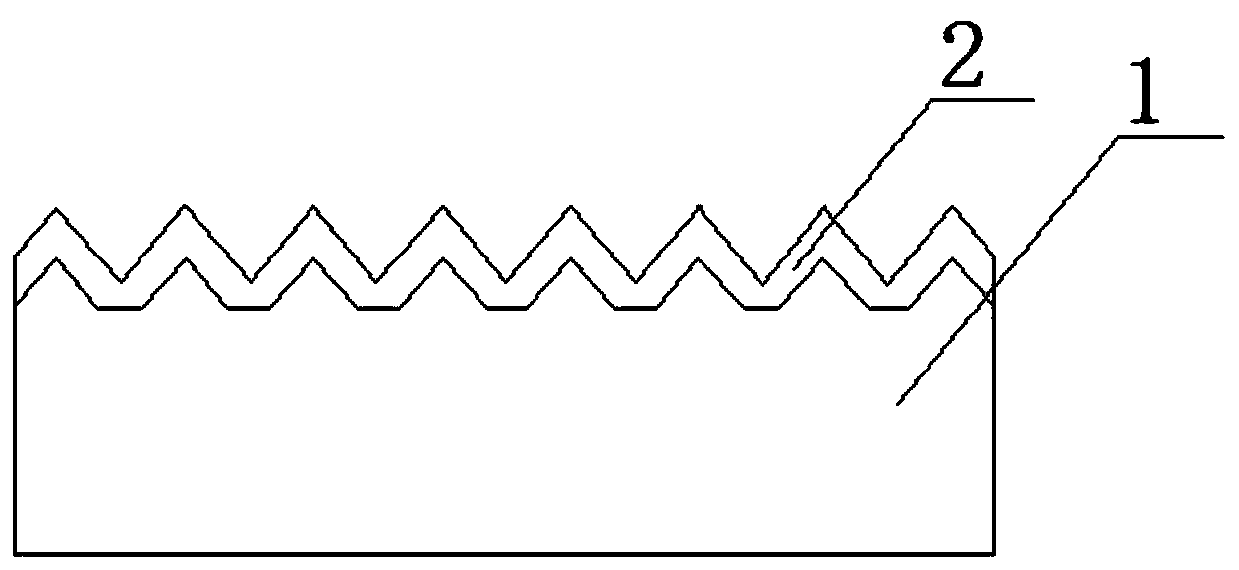

[0043]A passivated solar cell with printed metal electrodes in this embodiment includes an N-type crystalline silicon substrate 1, the back surface of the N-type crystalline silicon substrate 1 sequentially includes an n+ doped polysilicon layer 5, a back passivation antireflection Thin film 7, n+ metal electrode 9;

[0044] A doped polysilicon tail layer 6 is formed on the side of the N-type crystalline silicon substrate 1 close to the n+ doped polysilicon layer 5 .

[0045] The band tail of polysilicon doping, that is, the depth to which dopant atoms diffuse in crystalline silicon, plays a decisive role in the size of metal contact recombination. The research results show that the thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com