Method for separating lithium cobaltate and graphite in waste electrode material

An electrode material, lithium cobalt oxide technology, applied in the field of lithium cobalt oxide and graphite, can solve the problems of lithium cobalt oxide and graphite that have not yet been seen, and achieve the effect of low recycling cost, simple process flow, and increased surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

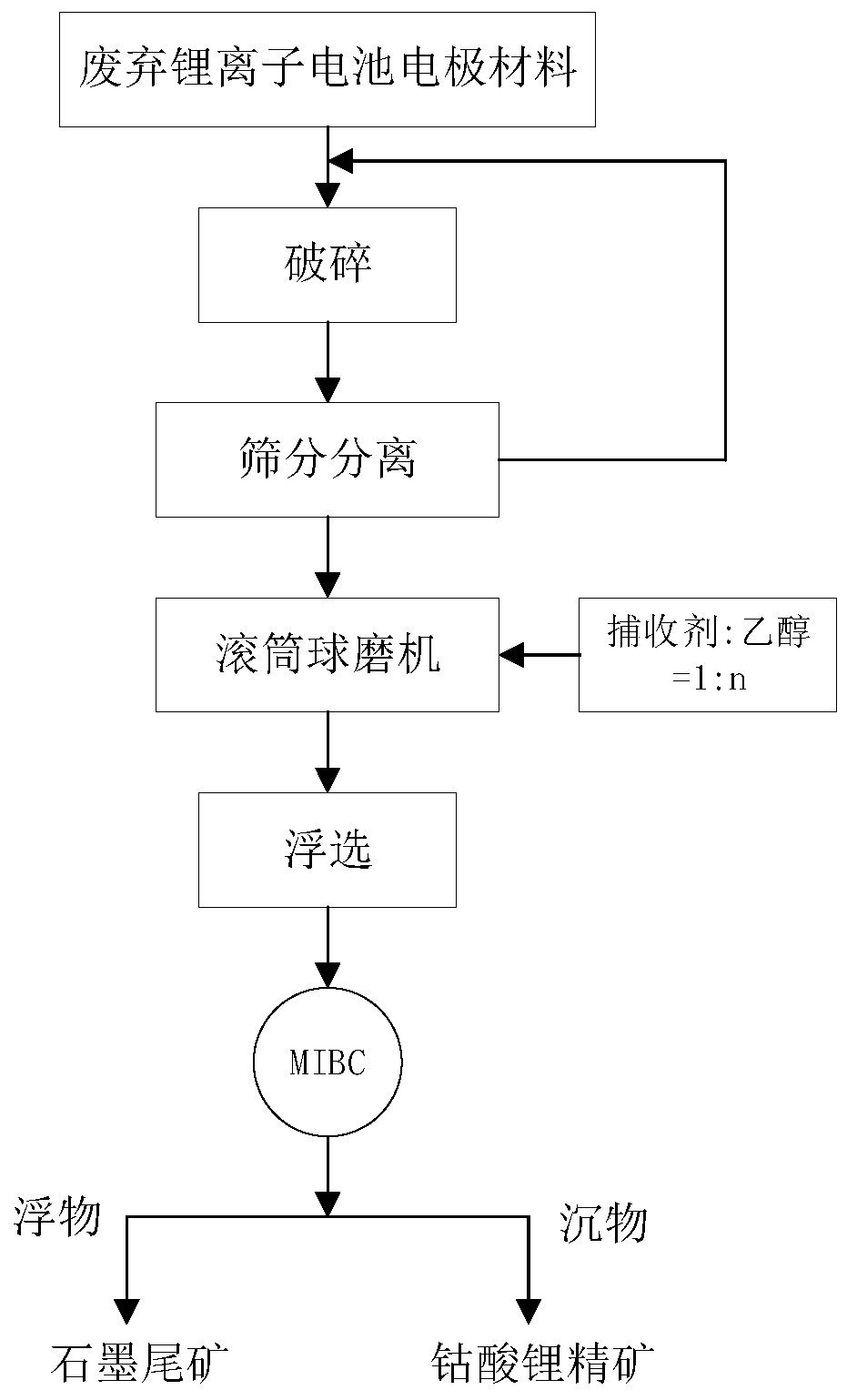

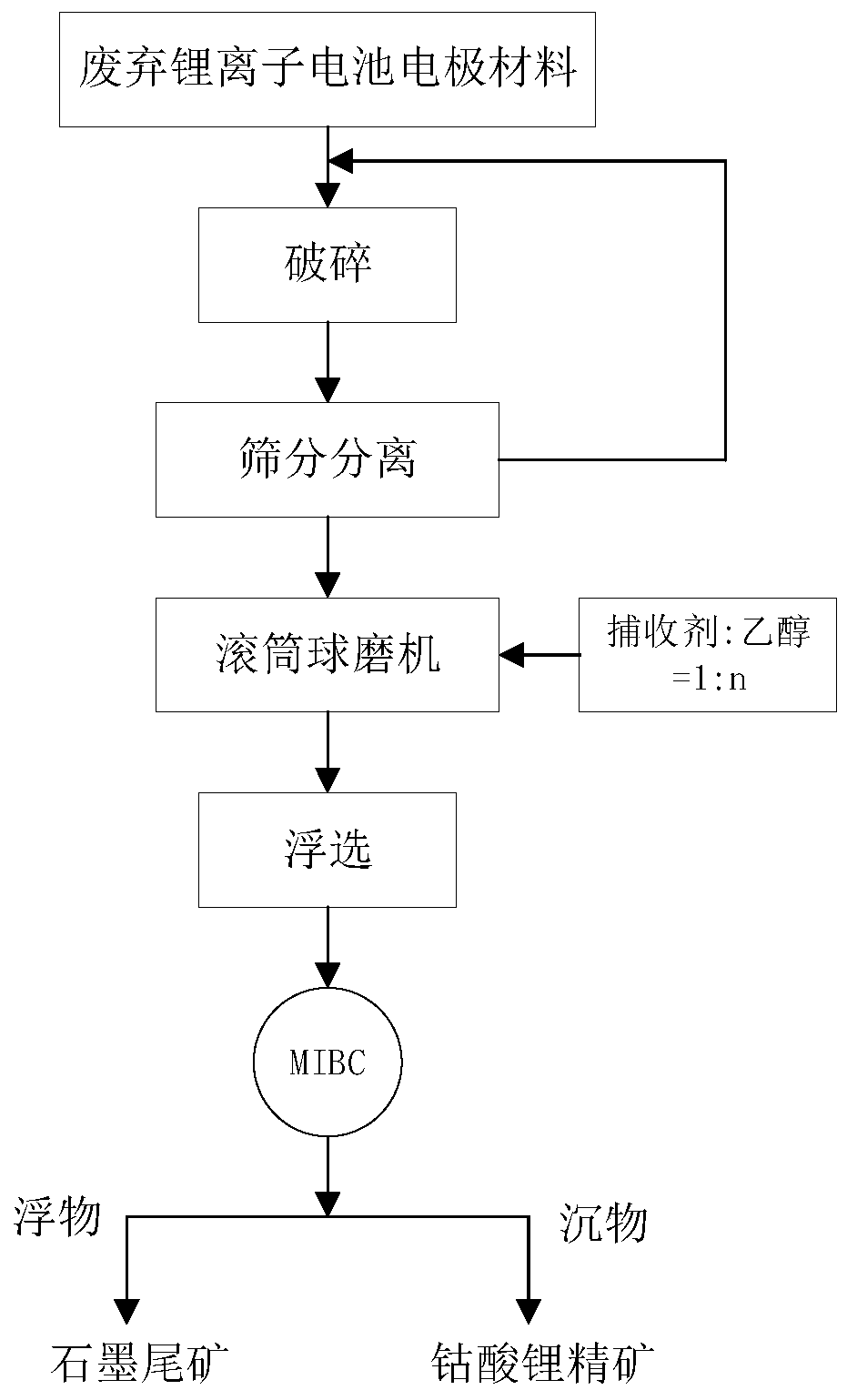

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] like figure 1 Shown is the method for strengthening flotation separation of lithium cobaltate and graphite in waste lithium-ion batteries by means of grinding and dosing, comprising the following steps:

[0024] (1) Discharge the waste lithium-ion battery, air dry it naturally for 24 hours, and manually disassemble it into positive electrode sheet, negative electrode sheet, separator and casing. Put the positive and negative plates together in a universal pulverizer to crush, and after sieving, obtain the under-sieve material with a particle size of less than 0.075mm;

[0025] (2) Mix the collector n-dodecane and ethanol evenly in advance according to a certain proportion, the mixing ratio is 1:n (n=1, 2, 3, 4, 5), and place the prepared mixed agent in the fine In the mouth bottle, prevent volatilization;

[0026] (3) Take 4g of the under-sieve material and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com