Preparation method of fast-growing eucalyptus bark activated carbon

A technology of fast-growing eucalyptus and activated carbon, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of natural environmental pollution, irrational use of biomass resources, etc., and achieve simple and convenient operation, good industrial application value, The effect of enriching the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

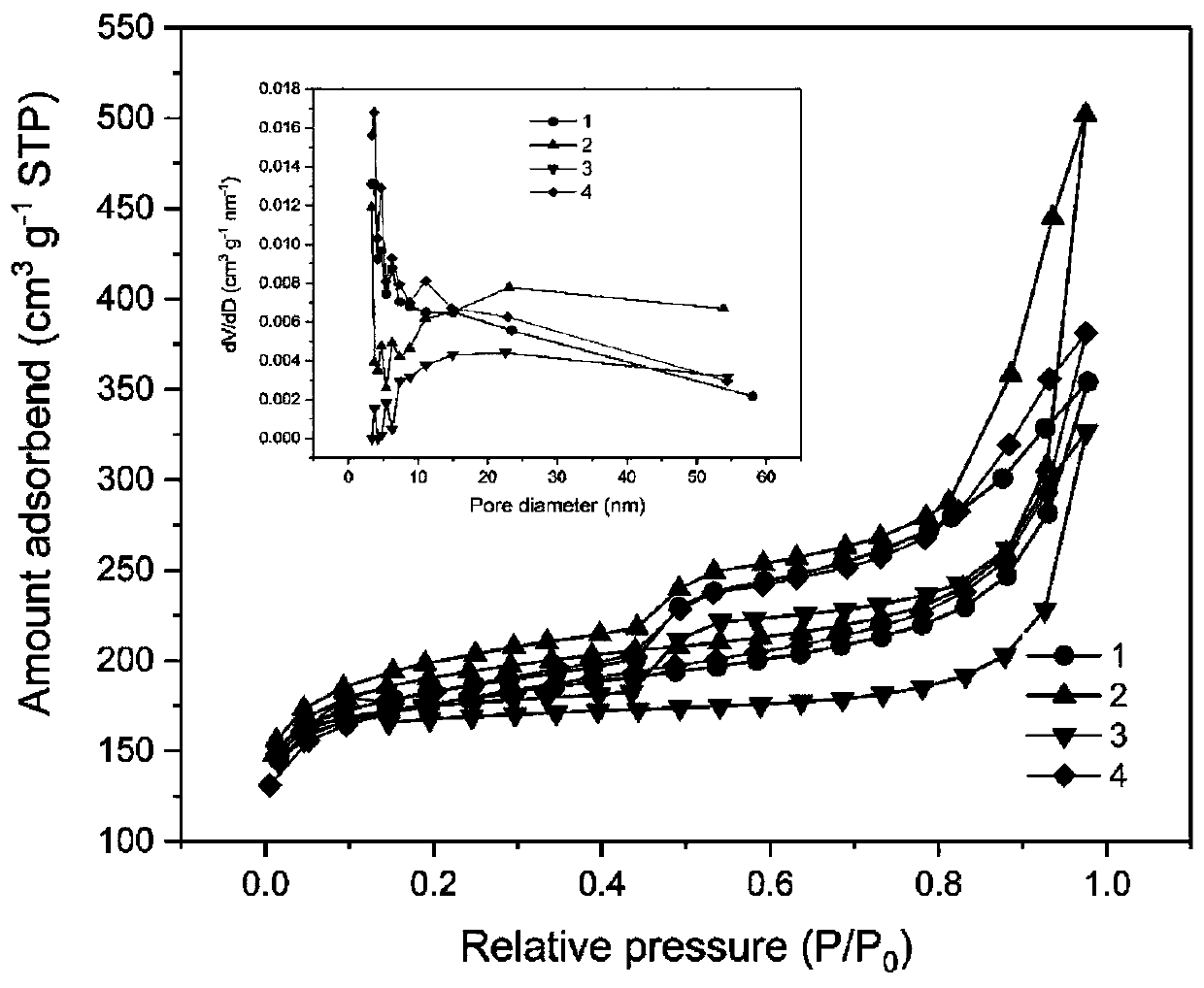

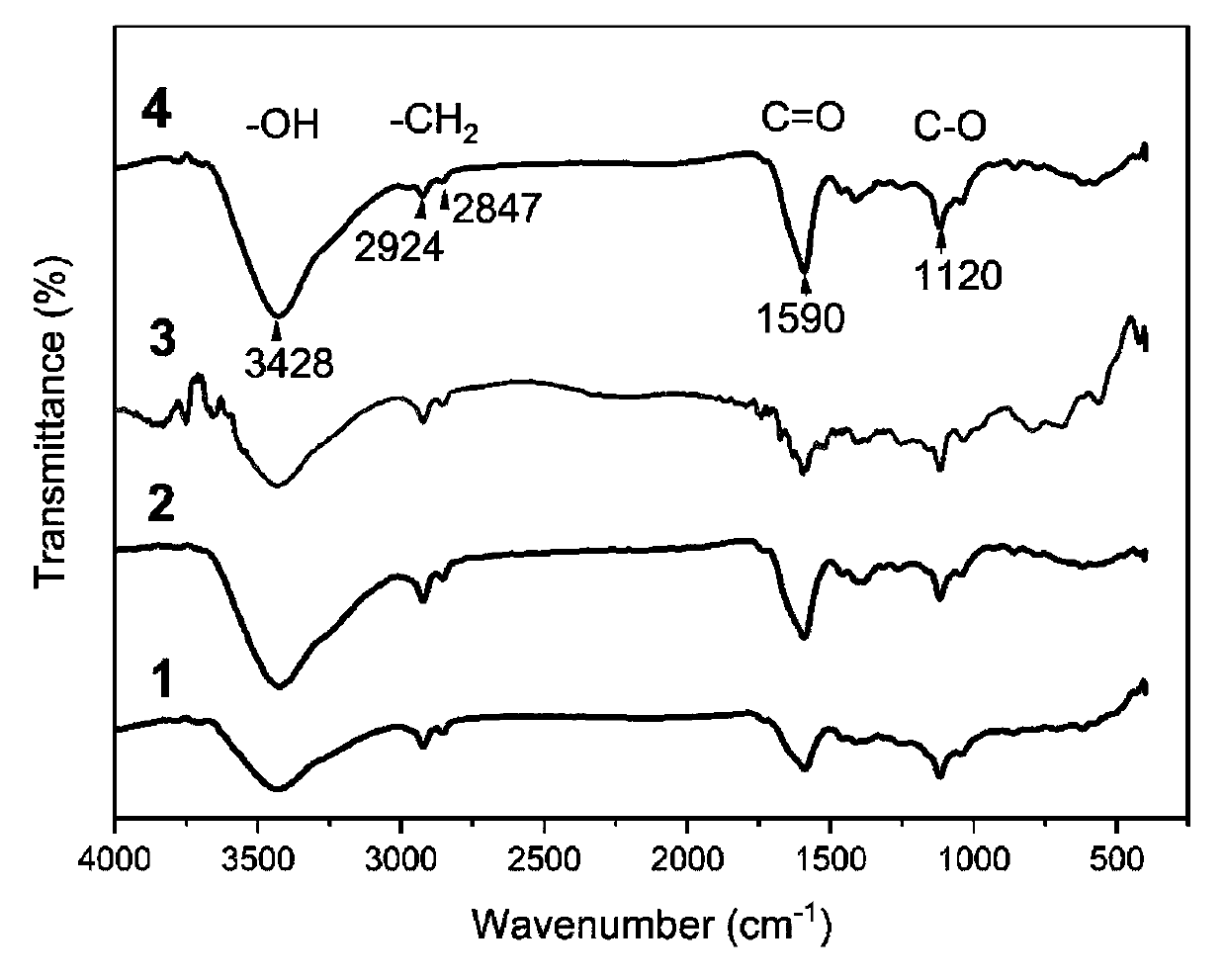

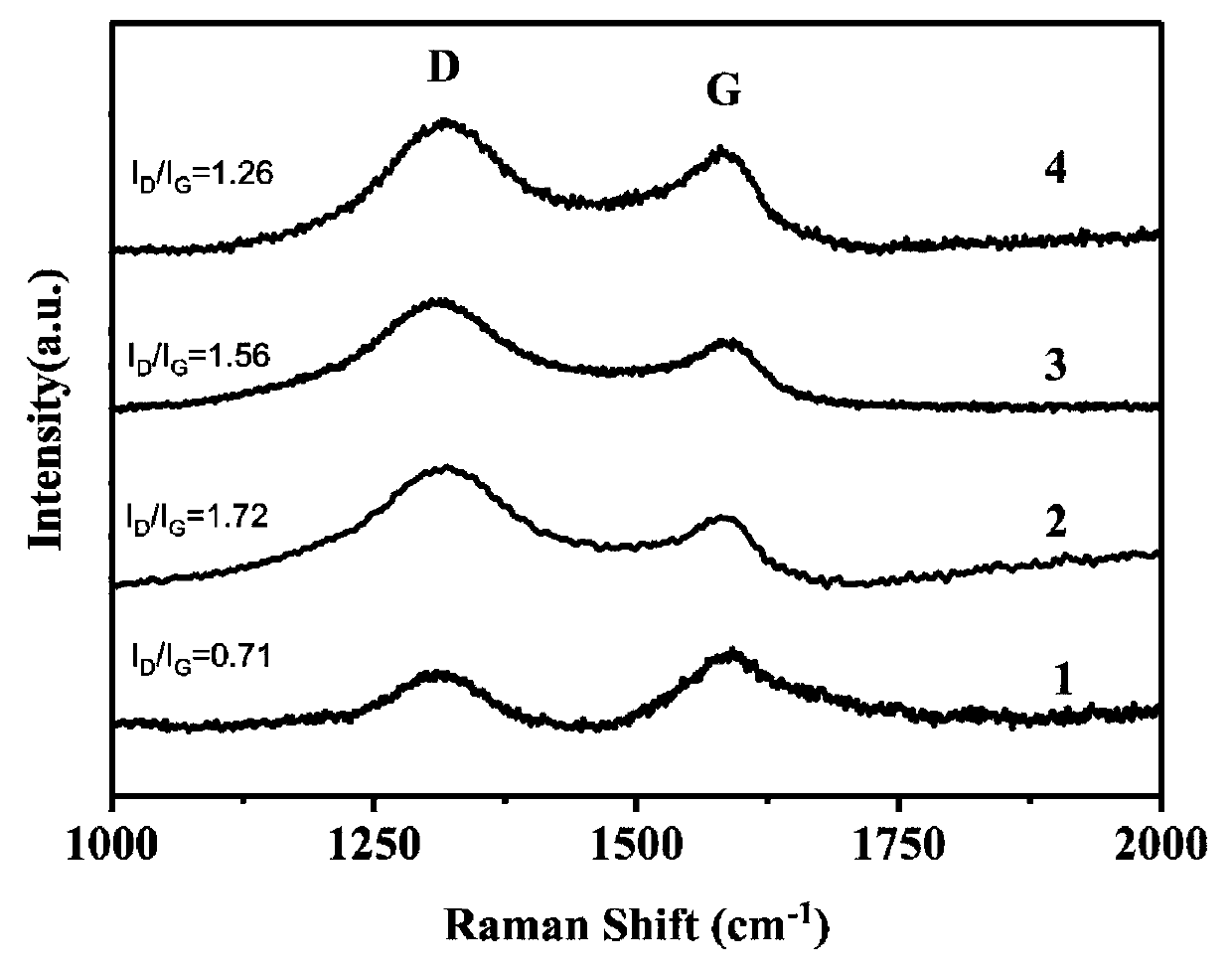

Embodiment 1

[0031] A preparation method of fast-growing eucalyptus bark activated carbon, comprising steps as follows:

[0032] (1) Wash the eucalyptus bark, dry it, put it into a pulverizer and crush it into chips, and place it in a drying oven at 105°C for 12 hours at a constant temperature, cool to room temperature, and seal it for storage;

[0033] (2) Mix the eucalyptus bark treated in step (1) with a deionized aqueous solution of potassium pyrophosphate, soak for 12 hours, wash and then place in a drying oven at 105° C. for constant temperature drying for 12 hours to obtain a pretreated sample;

[0034] (3) Place the pretreated sample obtained in step (2) in a tube furnace, pyrolyze and carbonize it under a nitrogen atmosphere, cool it down to 200°C naturally, take it out, cool it to room temperature, wash it with deionized water until it is neutral, and place it at 105 ℃ drying oven, and grind to obtain the fast-growing eucalyptus bark activated carbon;

[0035] Wherein, in the st...

Embodiment 2

[0037] A preparation method of fast-growing eucalyptus bark activated carbon, comprising steps as follows:

[0038] (1) Wash the eucalyptus bark, dry it, put it into a pulverizer and crush it into chips, and place it in a drying oven at 105°C for 12 hours at a constant temperature, cool to room temperature, and seal it for storage;

[0039] (2) Mix the eucalyptus bark treated in step (1) with a deionized aqueous solution of potassium pyrophosphate, soak for 12 hours, wash and then place in a drying oven at 105° C. for constant temperature drying for 12 hours to obtain a pretreated sample;

[0040] (3) Place the pretreated sample obtained in step (2) in a tube furnace, pyrolyze and carbonize it under a nitrogen atmosphere, naturally cool down to 180°C, take it out, cool it to room temperature, rinse it with deionized water until it is neutral, and place it at 105 ℃ drying oven, and grind to obtain the fast-growing eucalyptus bark activated carbon;

[0041] Wherein, in the step...

Embodiment 3

[0043] A preparation method of fast-growing eucalyptus bark activated carbon, comprising steps as follows:

[0044] (1) Wash the eucalyptus bark, dry it, put it into a pulverizer and crush it into chips, and place it in a drying oven at 105°C for 12 hours at a constant temperature, cool to room temperature, and seal it for storage;

[0045] (2) Mix the eucalyptus bark treated in step (1) with a deionized aqueous solution of potassium pyrophosphate, soak for 12 hours, wash and then place in a drying oven at 105° C. for constant temperature drying for 12 hours to obtain a pretreated sample;

[0046] (3) Place the pretreated sample obtained in step (2) in a tube furnace, pyrolyze and carbonize it under a nitrogen atmosphere, naturally cool down to 150°C, take it out, cool it to room temperature, rinse it with deionized water until it is neutral, and place it at 105 ℃ drying oven, and grind to obtain the fast-growing eucalyptus bark activated carbon;

[0047] Wherein, in the step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com