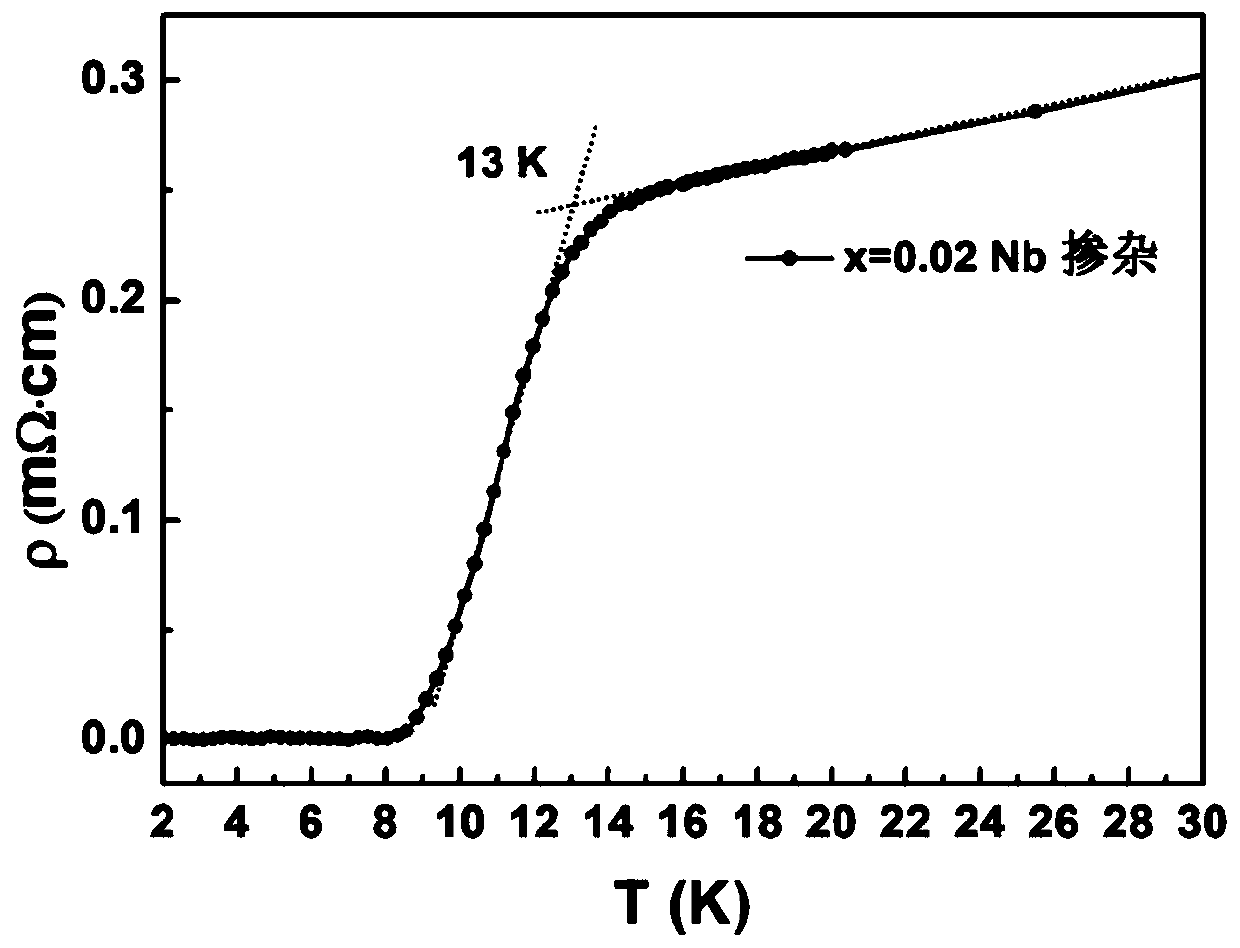

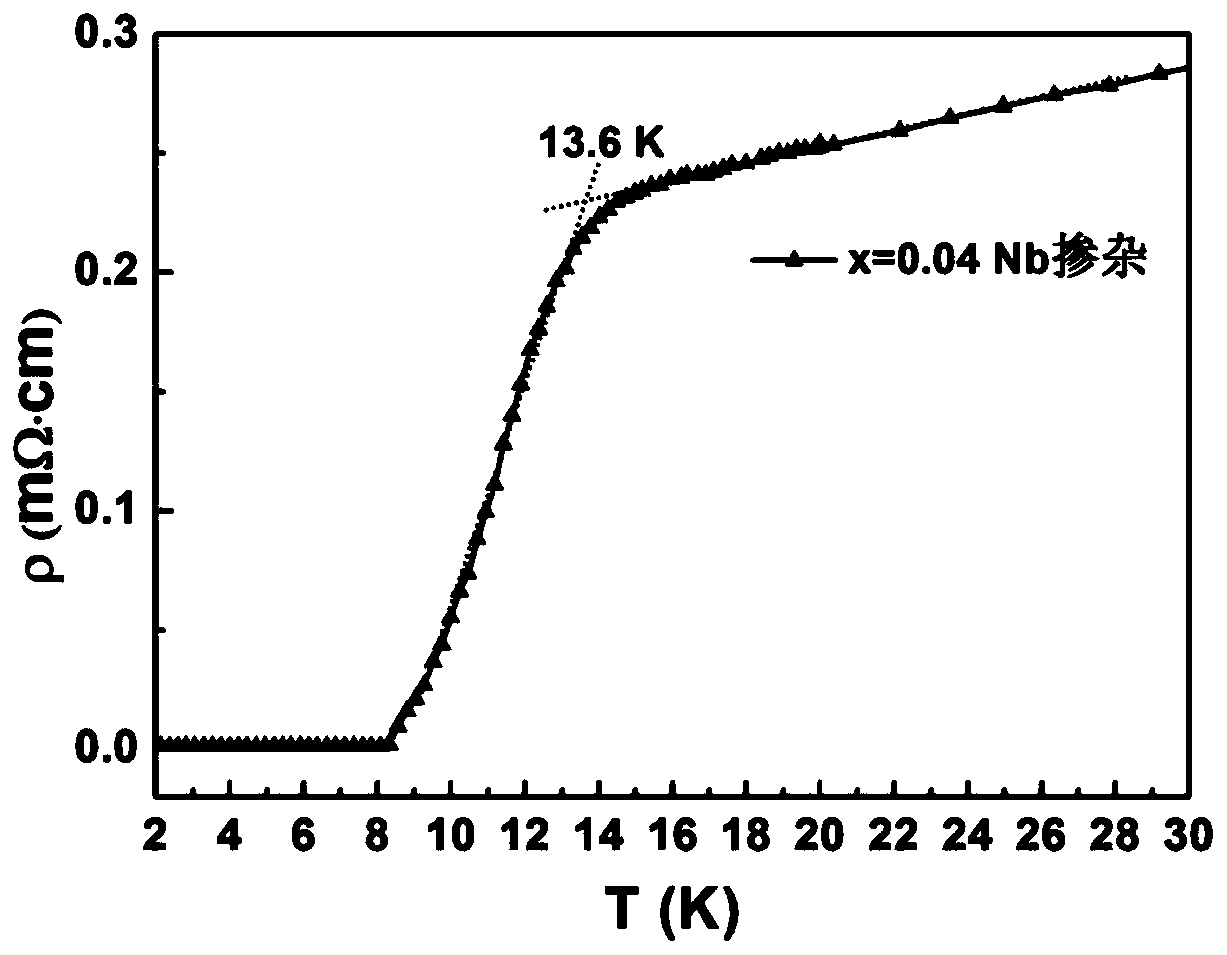

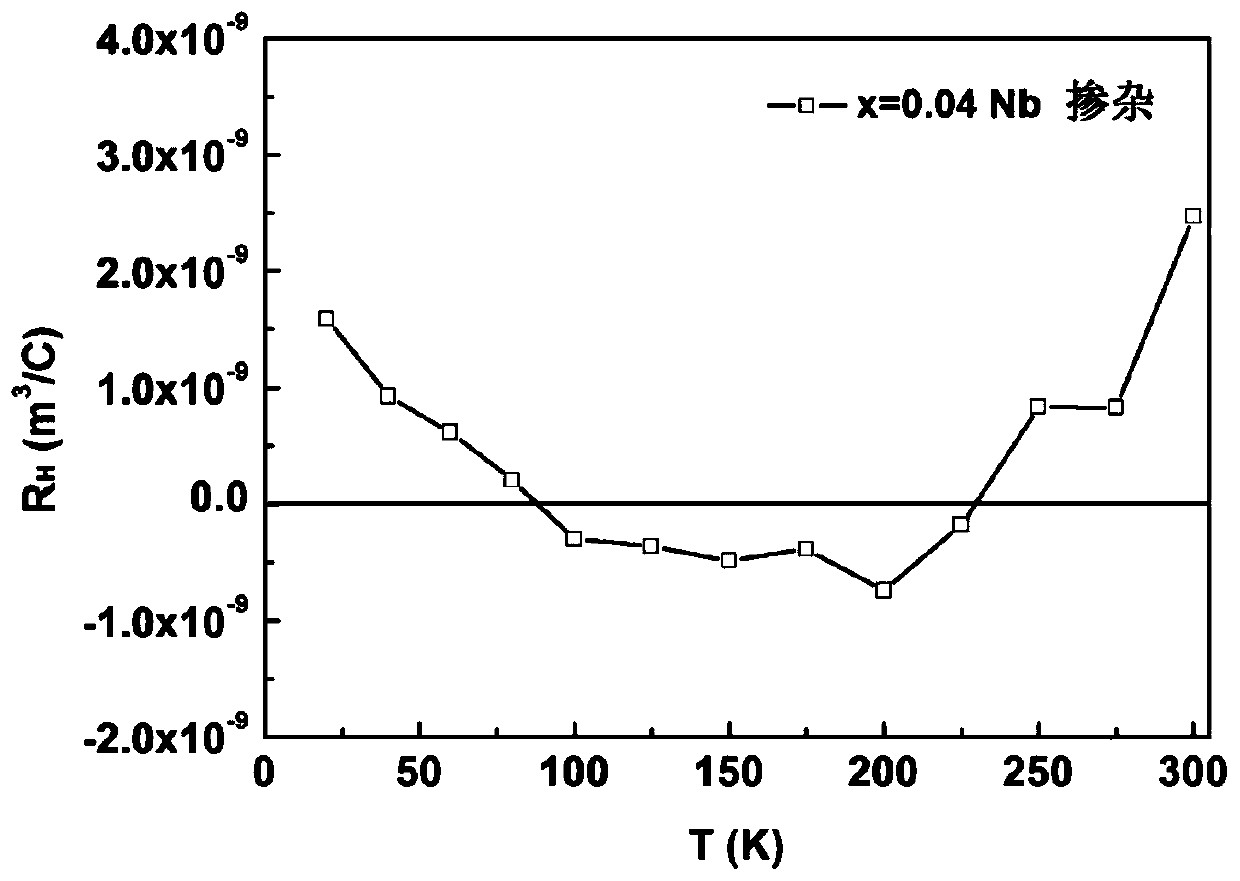

Method for improving Fe-Se superconducting transition temperature by Nb doping

A transition temperature, iron selenium technology, applied in the field of niobium doping to improve iron selenium superconducting transition temperature, can solve the problem that the influence of superconducting performance is not significant, and achieve the effect of increasing superconducting transition temperature and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Weigh 3.006g iron powder and 3.952g selenium powder (the purity of iron powder and selenium powder are both 99.5%, the atomic percentage of iron powder and selenium powder Fe:Se=1:0.93), fully in an agate mortar Grind for 20 minutes to obtain a uniformly mixed mixed powder. The weighing process and the grinding process are carried out in a glove box filled with high-purity argon; the ground mixed powder is compressed into a quartz tube and placed in a tube sintering furnace. , Sintered at 600 ℃ 72h, the furnace is cooled to room temperature.

[0032] (2) Take out the pre-sintered piece in the first step and put it in an agate mortar, and mix it with 0.1g of pure Nb powder (Nb powder purity 99.5%, atomic percentage of Nb and FeSe is FeSe:Nb=1:0.02 ) Grind for another 30 minutes to mix evenly.

[0033] (3) The obtained mixed powder is compressed again and placed in a tube sintering furnace, evacuated and filled with high-purity argon gas for sintering, sintered at 600°C f...

Embodiment 2

[0035] (1) Weigh 1.503g iron powder and 2.018g selenium powder (the purity of iron powder and selenium powder are both 99.5%, the atomic percentage of iron powder and selenium powder Fe:Se=1:0.95), fully in an agate mortar Grind for 30 minutes to obtain a uniformly mixed mixed powder. The weighing process and the grinding process are carried out in a glove box filled with high-purity argon; the ground mixed powder is compressed and vacuum-sealed into a quartz tube and then placed in a tube sintering furnace , Sintered at 650℃ for 72h, the furnace is cooled to room temperature.

[0036] (2) Take out the pre-sintered piece in the first step and put it in an agate mortar, mix it with 0.1g of pure Nb powder (Nb powder purity 99.5%, atomic percentage of Nb and FeSe is FeSe:Nb=1:0.04). ), then grind for 40 minutes to mix evenly.

[0037] (3) The obtained mixed powder is compressed again and placed in a tube sintering furnace, evacuated and filled with high-purity argon gas for sintering...

Embodiment 3

[0039] (1) Weigh 1.202g iron powder and 1.615g selenium powder (the purity of iron powder and selenium powder are both 99.5%, the atomic percentage of iron powder and selenium powder Fe:Se=1:0.95), fully in an agate mortar Grind for 30 minutes to obtain a uniformly mixed mixed powder. The weighing process and the grinding process are carried out in a glove box filled with high-purity argon; the ground mixed powder is compressed and vacuum-sealed into a quartz tube and then placed in a tube sintering furnace , Sintered at 650℃ for 72h, the furnace is cooled to room temperature.

[0040] (2) Take out the pre-sintered piece in the first step and put it in an agate mortar, and mix it with 0.1g of pure Nb powder (Nb powder purity 99.5%, atomic percentage of Nb and FeSe is FeSe:Nb=1:0.05). ), then grind for 40 minutes to mix evenly.

[0041] (3) The obtained mixed powder is compressed again and placed in a tube sintering furnace, evacuated and filled with high-purity argon gas for sinte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Superconducting transition temperature | aaaaa | aaaaa |

| Superconducting transition temperature | aaaaa | aaaaa |

| Superconducting transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com