LED curable UV adhesive for laser transfer paper and preparation method of adhesive

A technology of laser transfer paper and radiation curing, applied in the field of ink, can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

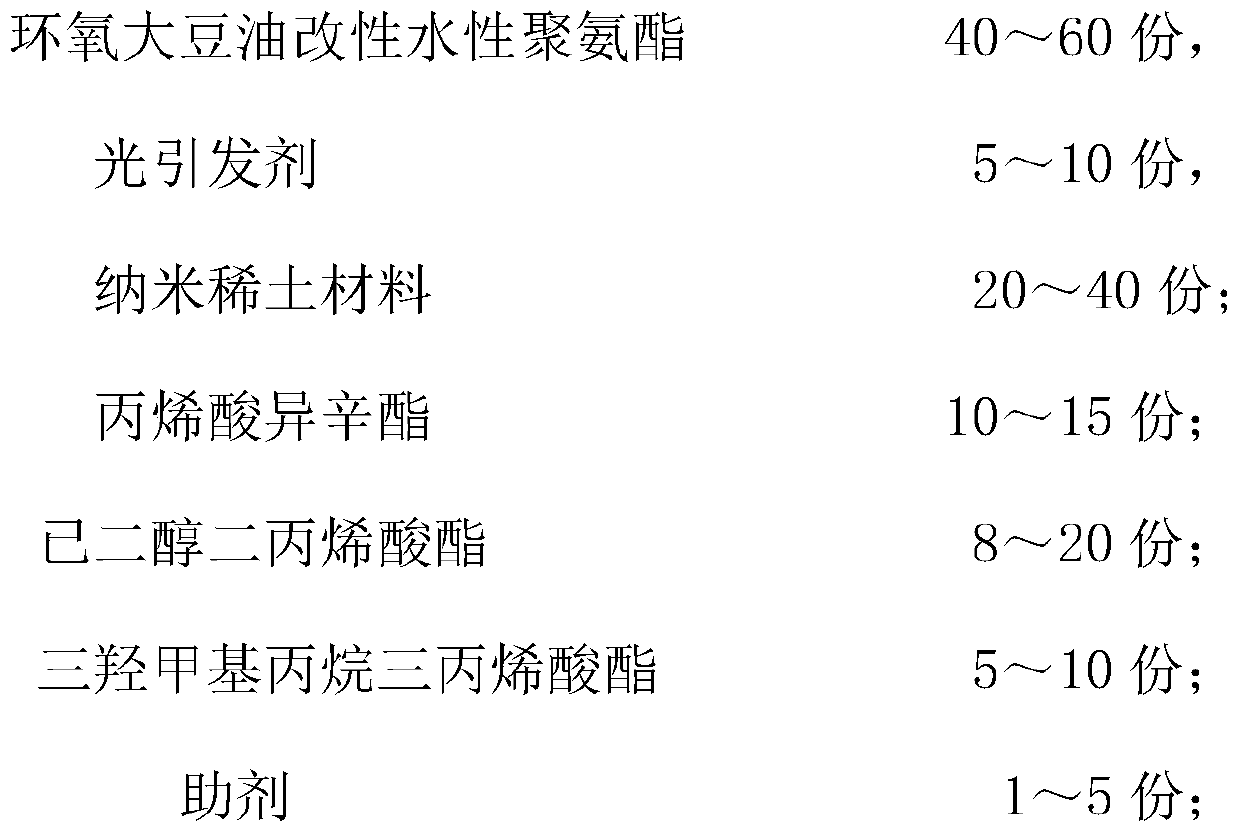

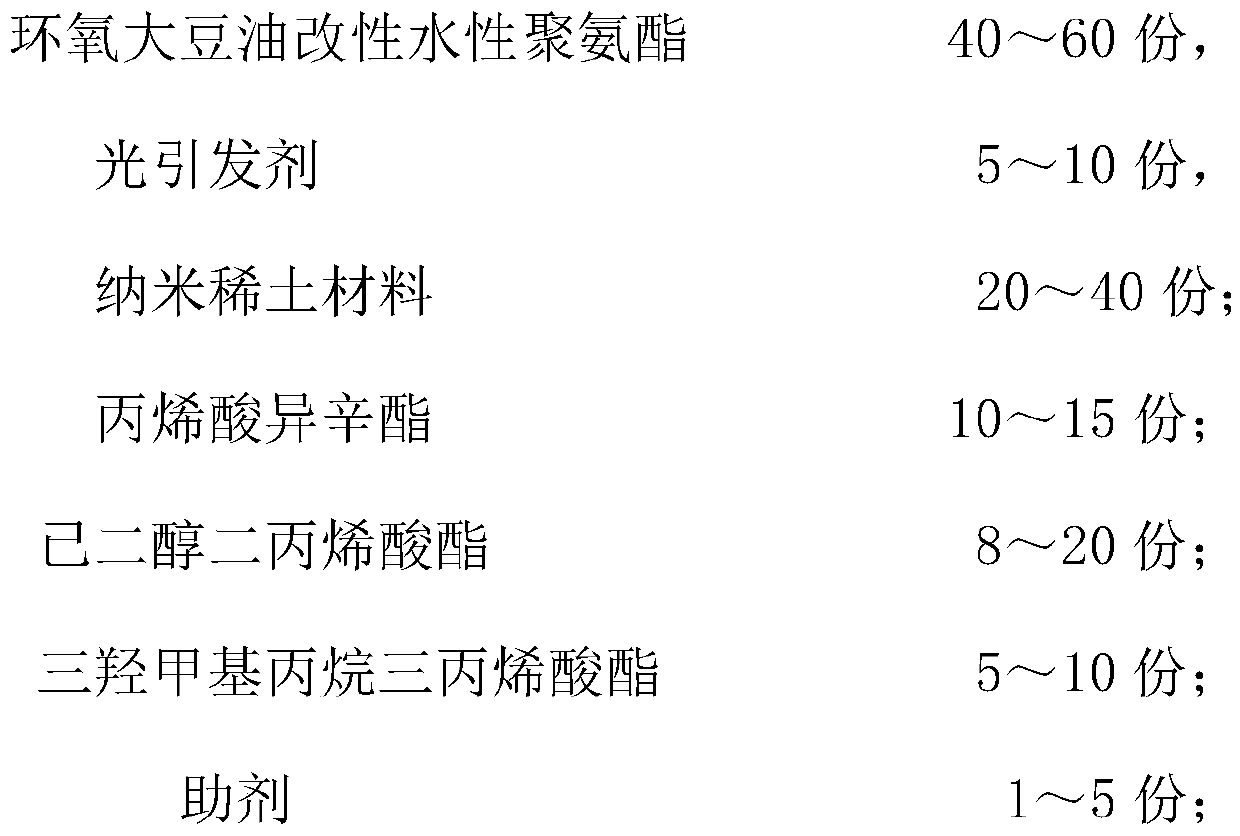

Method used

Image

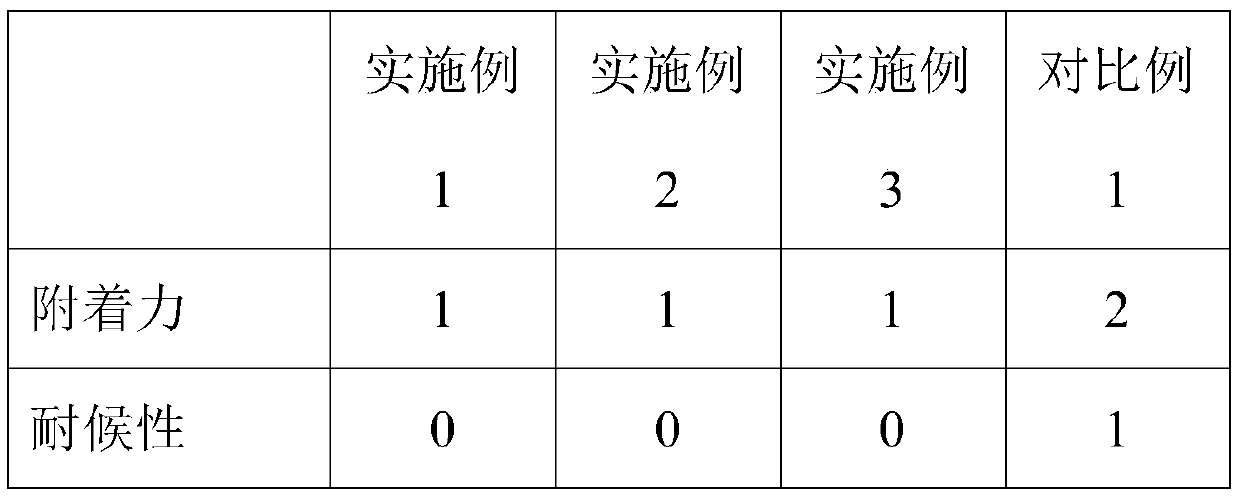

Examples

Embodiment 1

[0026] A kind of laser transfer paper LED curing UV glue, according to the mass fraction, including the following composition and components: 40 parts of epoxy soybean oil modified water-based polyurethane, 5 parts of photoinitiator, 10 parts of isooctyl acrylate; 8 parts of acrylate, 5 parts of trimethylolpropane triacrylate, 7 parts of nano-cerium oxide, 7 parts of nano-yttrium oxide, 6 parts of nano-gadolinium oxide; 1 part of additive, 0.2 parts of BYK-333 leveling agent, antioxidant 0.2 parts, 0.2 parts of anti-aging agent, 0.2 parts of stabilizer, 0.2 parts of adhesion enhancer.

[0027] Photoinitiator is made up of the component of following percentage by weight:

[0028] 2,4,6-Trimethylbenzoyl-diphenylphosphine oxide 48%;

[0029] 2-Dimethylamino-2-benzyl-1-[-4(4-morpholinyl)phenyl]-1-butanone 35%;

[0030] 2,4-Diethylthioxanthone 17%.

[0031] The preparation method of the laser transfer paper LED curing UV glue comprises the following steps:

[0032] (1) Preparat...

Embodiment 2

[0036] A laser transfer paper LED curing UV glue, according to the mass fraction, including the following composition and components:

[0037] 60 parts of epoxy soybean oil modified water-based polyurethane, 10 parts of photoinitiator, 15 parts of isooctyl acrylate, 20 parts of hexanediol diacrylate, 10 parts of trimethylolpropane triacrylate, 8 parts of nano samarium oxide, 8 parts of nano dysprosium oxide, 8 parts of nano europium oxide, 4 parts of nano praseodymium oxide, 4 parts of nano holmium oxide, 4 parts of nano lanthanum oxide, 4 parts of nano neodymium oxide; 2 parts of BYK-333 leveling agent, 2 parts of antioxidant , Anti-aging agent 1 part.

[0038] Photoinitiator is made up of the component of following percentage by weight:

[0039] 2,4,6-Trimethylbenzoyl-diphenylphosphine oxide 48%;

[0040] 2-Dimethylamino-2-benzyl-1-[-4(4-morpholinyl)phenyl]-1-butanone 35%;

[0041] 2,4-Diethylthioxanthone 17%.

[0042] The preparation method of the laser transfer paper L...

Embodiment 3

[0047] A laser transfer paper LED curing UV glue, according to the mass fraction, including the following composition and components:

[0048] 50 parts of epoxy soybean oil modified water-based polyurethane, 8 parts of photoinitiator, 12 parts of isooctyl acrylate, 15 parts of hexanediol diacrylate, 8 parts of trimethylolpropane triacrylate, 30 parts of nano-oxidized bait; 2 parts of BYK-333 leveling agent.

[0049] Photoinitiator is made up of the component of following percentage by weight:

[0050] 2,4,6-Trimethylbenzoyl-diphenylphosphine oxide 48%;

[0051] 2-Dimethylamino-2-benzyl-1-[-4(4-morpholinyl)phenyl]-1-butanone 35%;

[0052] 2,4-Diethylthioxanthone 17%.

[0053] The preparation method of the laser transfer paper LED curing UV glue comprises the following steps:

[0054] (1) Preparation of epoxy soybean oil modified waterborne polyurethane

[0055] Add polyoxypropylene diol and toluene diisocyanate into the reaction vessel, react at 80°C for 2 hours, then add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap