Application of hydrocyclone separation technology in MCP device

A technology of hydrocyclone and hydrocyclone, which is applied in the field of oil slurry, can solve the problems of high solid content of oil slurry in fractionation system, decrease of light oil yield of equipment, increase of energy consumption of equipment burning, etc., and reach the production and adjustment range wide, low manufacturing cost, and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

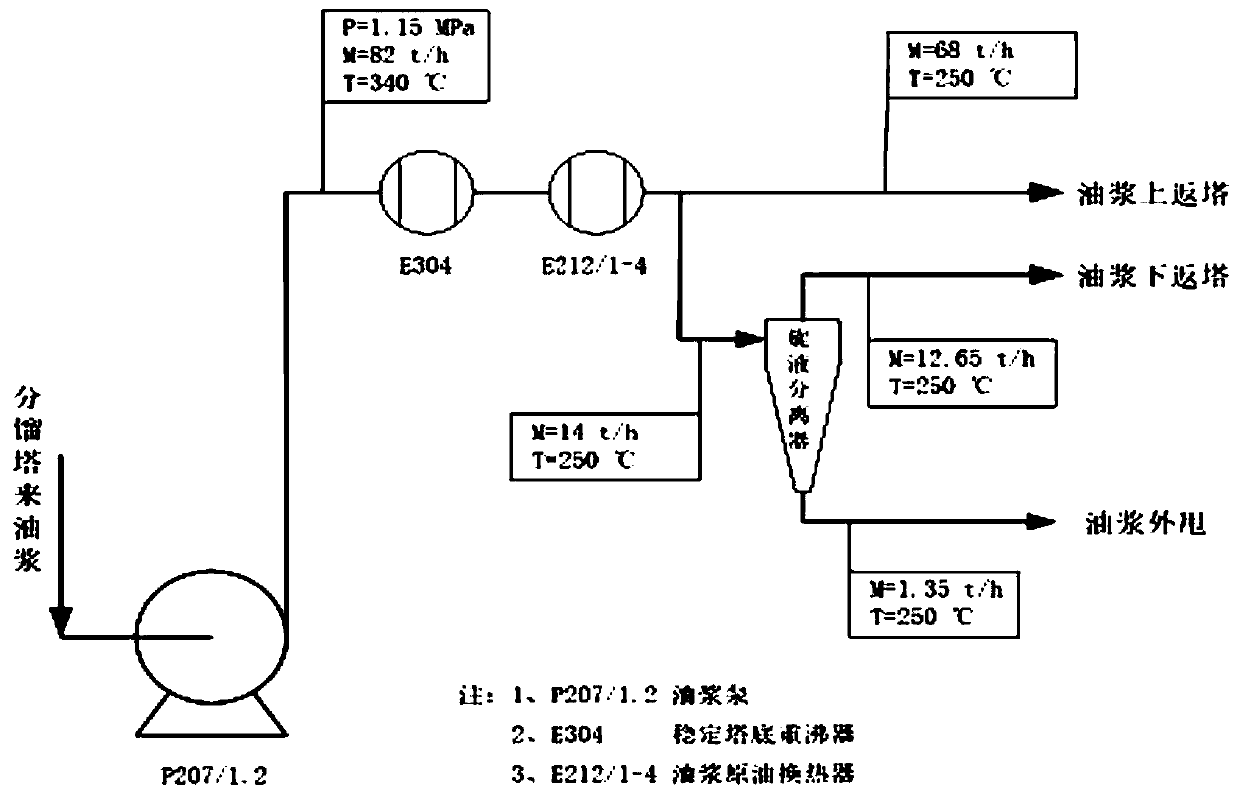

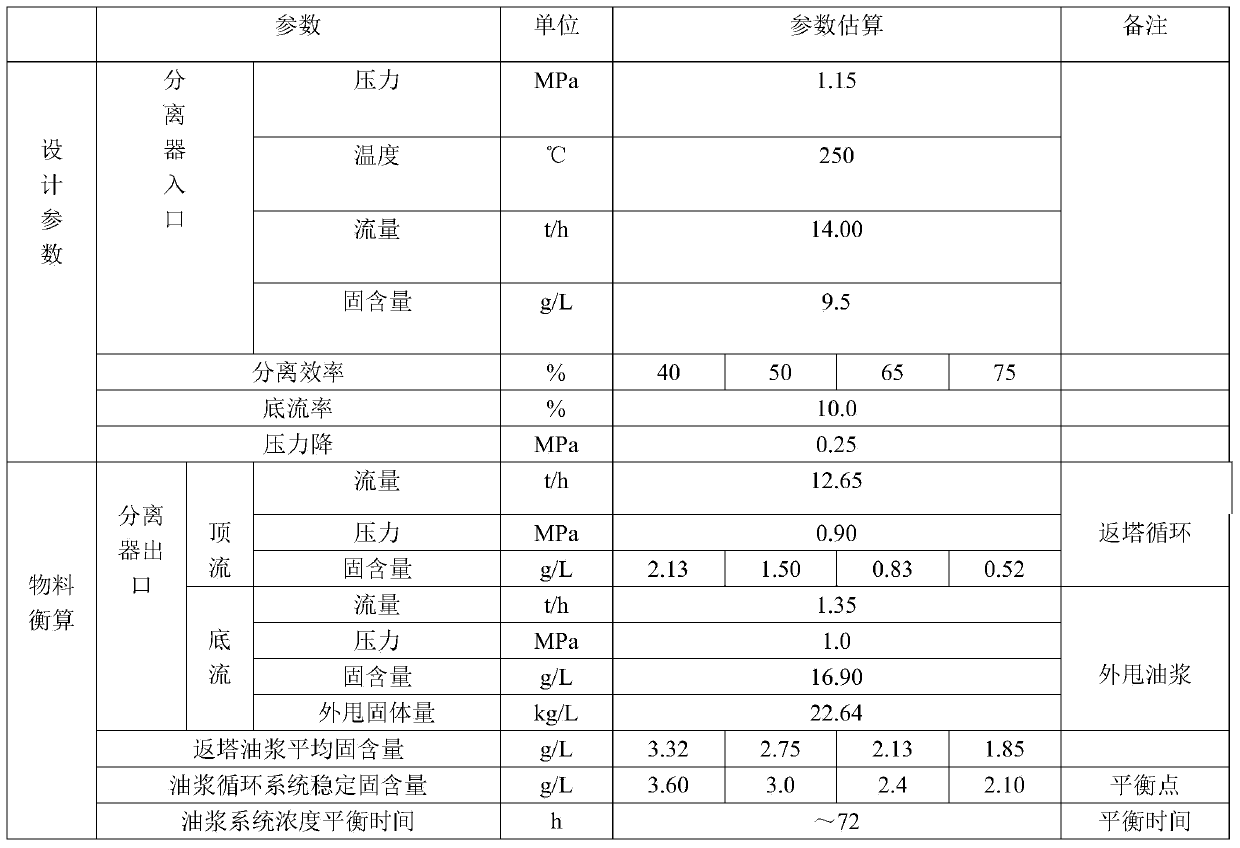

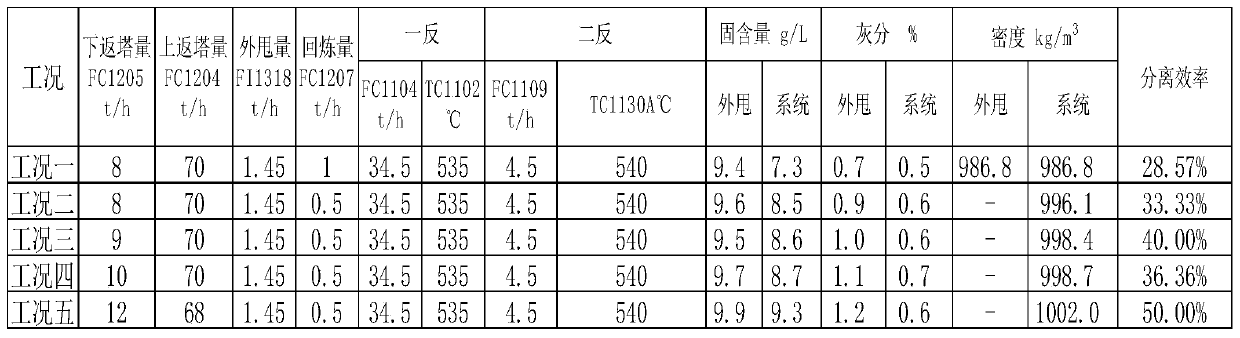

[0026] The oil slurry in the fractionation tower passes through the oil slurry, after being subjected to high temperature and high pressure, and then flows through the bottom reboiler of the stable tower, the oil slurry crude oil heat exchanger at a certain flow rate, and after cooling to a certain temperature, a part of the oil slurry passes through at a certain flow rate. The pipeline flows back to the fractionation tower, and another part of the oil slurry flows into the liquid inlet of the hydrocyclone at a certain flow rate, and then flows into the cyclone head through the outer wall of the clearing tube, and the outer wall of the clearing tube is provided with a spiral structure, and the lower end of the cyclone is funnel-shaped. After entering the lower end of the hydrocyclone and undergoing high-speed rotary motion, the clear and heavy oil slurry is separated, and the clear flow returns to the upper part of the hydrocyclone through the clear flow pipe to flow out, and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com