Multi-layer film type high-sensitivity heat-sensitive temperature chip and manufacturing method thereof

A heat-sensitive temperature and high-sensitivity technology, which is applied to thermometers, coatings, thermometers, etc. that are directly sensitive to heat-sensitive electric/magnetic components, can solve the problem that microcircuit miniaturization cannot be applied, and chips cannot achieve high-sensitivity measurement , slow chip response speed and other issues, to achieve the effect of miniaturization, resistance reduction, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

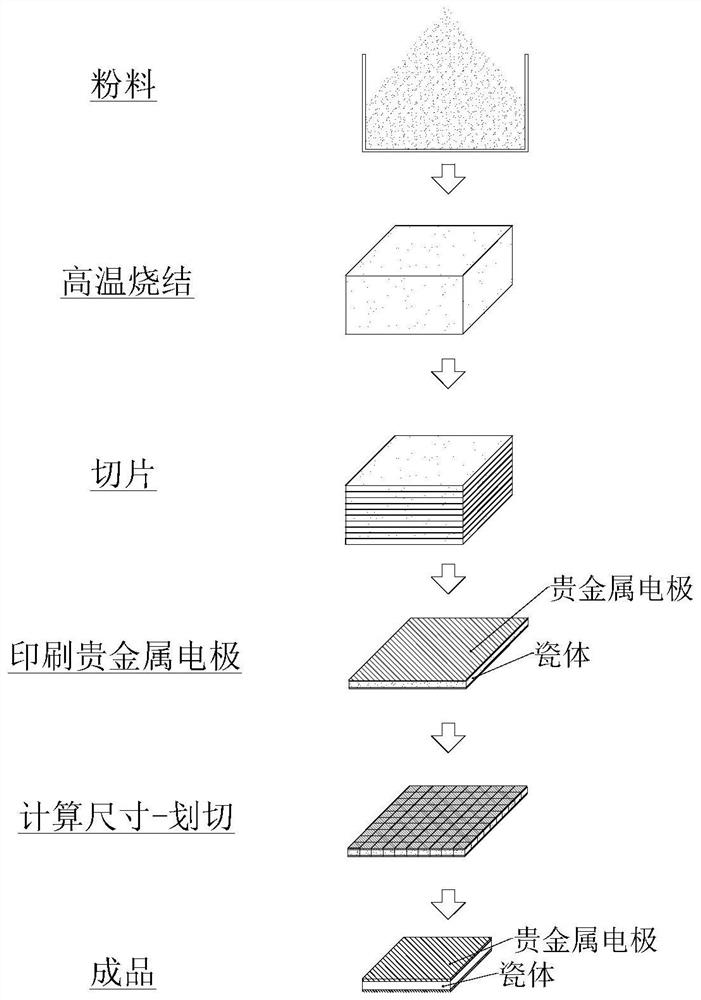

Method used

Image

Examples

Embodiment 1

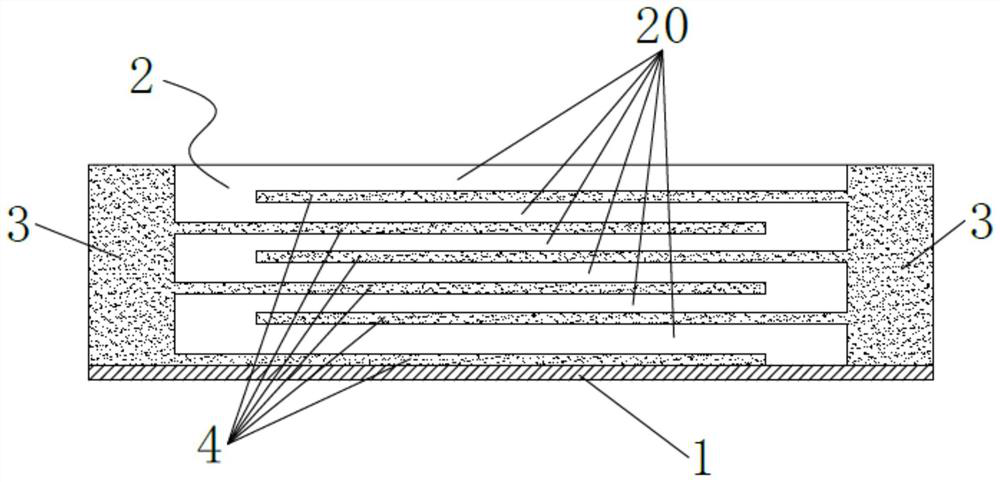

[0054] In this example, N is selected as 6, and NTC heat-sensitive ceramic powder with a resistivity of 2000Ω·m at 25°C is prepared according to the existing conventional formula, and pressed and sintered into an ingot, and then the prepared ceramic ingot is used as a sputtering The target material of the ceramic film 20 uses silver as the target material of the sputtering metal film 4, and according to the preparation method of the present invention, the heat-sensitive temperature chip with a size of about 0.3 mm in length, 0.3 mm in width and 0.005 mm in thickness is produced, measured The resistance value of the heat-sensitive temperature chip at 25° C. is about 6 kΩ.

[0055] It can be seen that the heat-sensitive temperature chip described in the present invention can realize small size, low resistance value and high B value at the same time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com