All-inorganic white light LED packaging structure and preparation method thereof

A technology of LED packaging and LED chips, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems that affect the long-term reliability of white light LEDs, it is difficult to meet the lighting requirements, and the aging of organic materials, so as to avoid aging and failure problems. Improve packaging efficiency and integration, and avoid thermal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

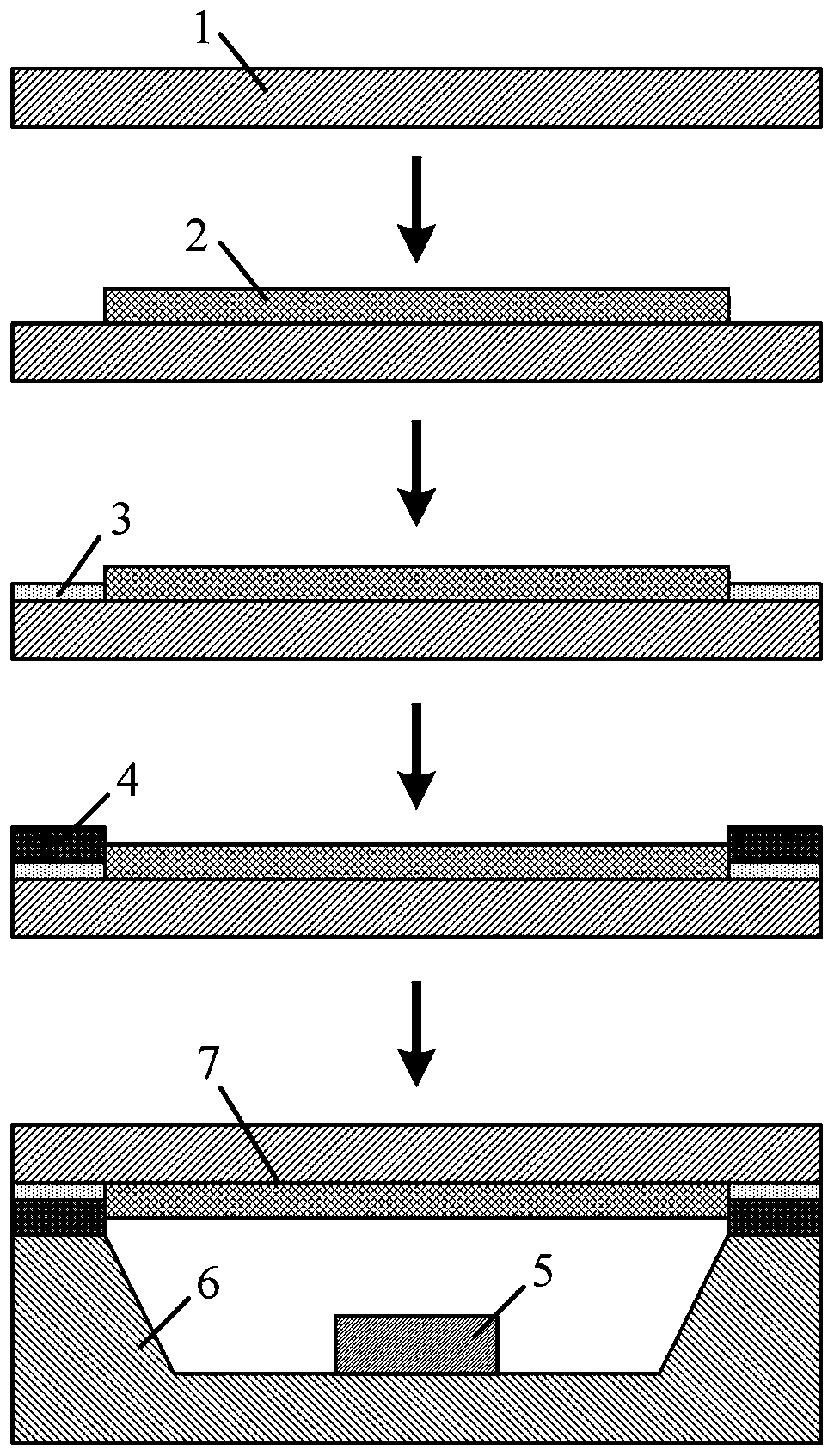

[0045] Such as figure 1 As shown, the steps of preparing the all-inorganic white LED packaging structure include:

[0046] (a) Mix 3g of terpineol and 0.15g of ethyl cellulose, and stir ultrasonically at 70°C until the ethyl cellulose is completely dissolved as a binder for the glass slurry, then add 12.6g of YAG yellow fluorescent powder and 5g of low-temperature borosilicate glass powder, and finally obtain the fluorescent glass slurry by magnetic stirring for 15 minutes; choose ordinary soda-lime glass as the substrate, and coat a layer of uniform thickness on one side of the glass sheet 1 by screen printing. The fluorescent glass paste is then placed in a high-temperature furnace, heated and sintered at 600° C. for 30 minutes to form a fluorescent glass layer 2 with a thickness of 90 μm;

[0047] (b) printing a layer of nano-silver paste around the fluorescent glass layer 2 obtained in step (a), and forming a sintered silver layer with uniform thickness by low-temperature...

Embodiment 2

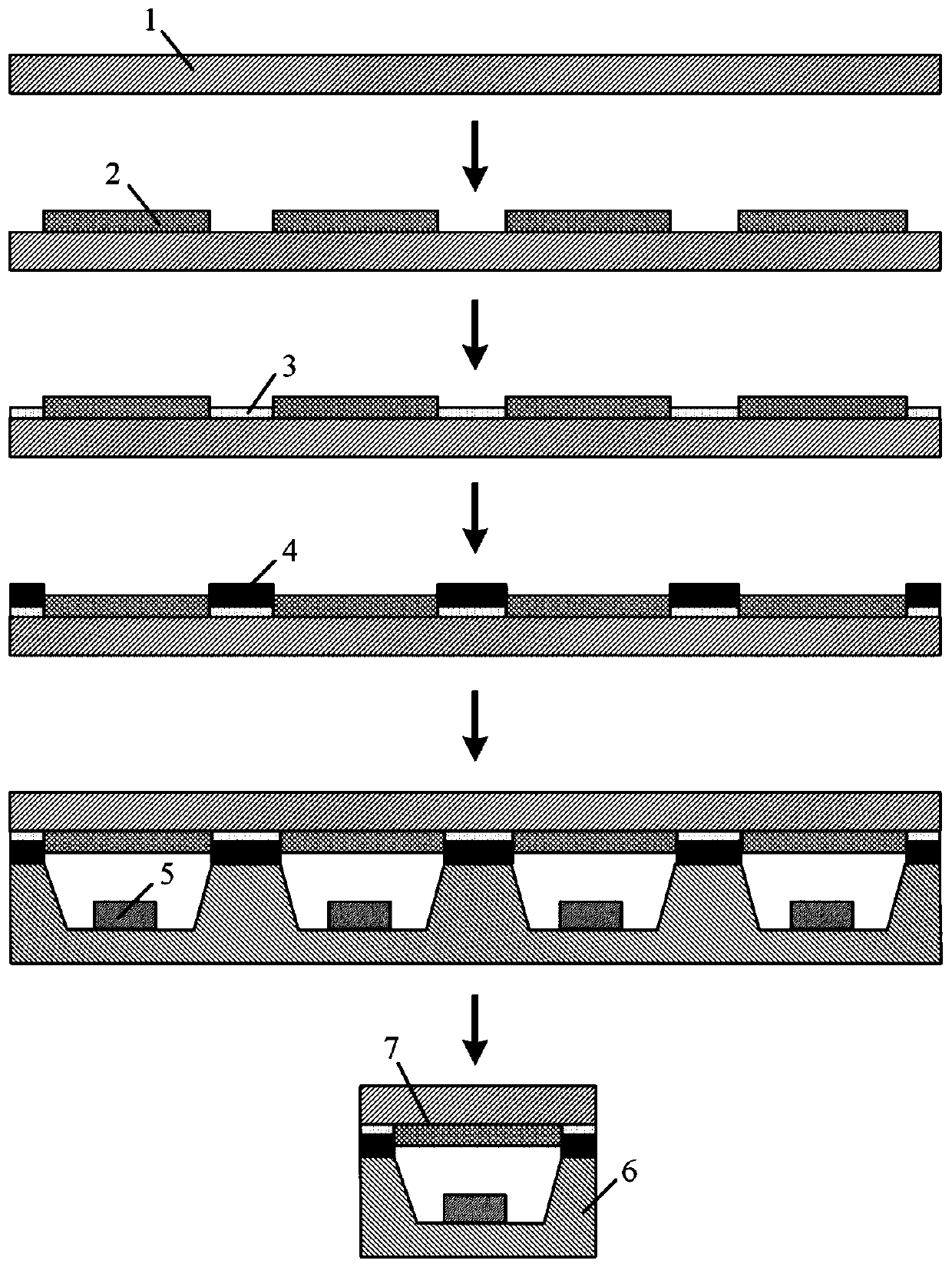

[0051] Such as figure 2 As shown, the steps of preparing the all-inorganic white LED packaging structure include:

[0052] (a) Mix 4g of terpineol and 0.2g of ethyl cellulose, and stir ultrasonically at 70°C until the ethyl cellulose is completely dissolved as a binder for the glass slurry, then add 3g of YAG yellow fluorescent powder, 1g of CASN red fluorescent powder and 6g of low-temperature tellurite glass powder, and finally obtain the fluorescent glass slurry by magnetically stirring for 15 minutes; select a wafer-level quartz glass sheet as the substrate, and coat one side of the glass sheet 1 by screen printing A layer of the fluorescent glass paste with a uniform thickness is placed in a high-temperature furnace, heated and sintered at 500° C. for 60 minutes to form a fluorescent glass layer 2 with a thickness of 150 μm;

[0053] (b) On one side of the fluorescent glass layer 2 obtained in step (a), form a mask pattern by photolithography and development, and then f...

Embodiment 3

[0057] The steps of preparing the all-inorganic white LED packaging structure include:

[0058] (a) Mix 6g of terpineol and 0.4g of ethyl cellulose, and stir ultrasonically at 70°C until the ethyl cellulose is completely dissolved as a binder for the glass slurry, and then add 2.5g of YAG yellow fluorescent powder and 25.4g of low-temperature borosilicate glass powder, and finally obtain fluorescent glass slurry by magnetically stirring for 15 minutes; choose ordinary soda-lime glass as the substrate, and coat a layer of fluorescent glass with a uniform thickness on one side of the glass sheet 1 by screen printing. The glass paste is then placed in a high-temperature furnace, heated and sintered at 650° C. for 20 minutes to form a fluorescent glass layer 2 with a thickness of 30 μm;

[0059] (b) printing a layer of nano-copper paste around the fluorescent glass layer 2 obtained in step (a), and forming a sintered copper layer with uniform thickness by low-temperature sintering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com