Method for enhancing performance of ECR (Electron Cyclotron Resonance) plasma source

A plasma source and plasma technology, applied in the field of ion source applications, can solve problems such as low beam density and insufficient performance parameters, and achieve the effect of enhancing ionization efficiency and improving plasma performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

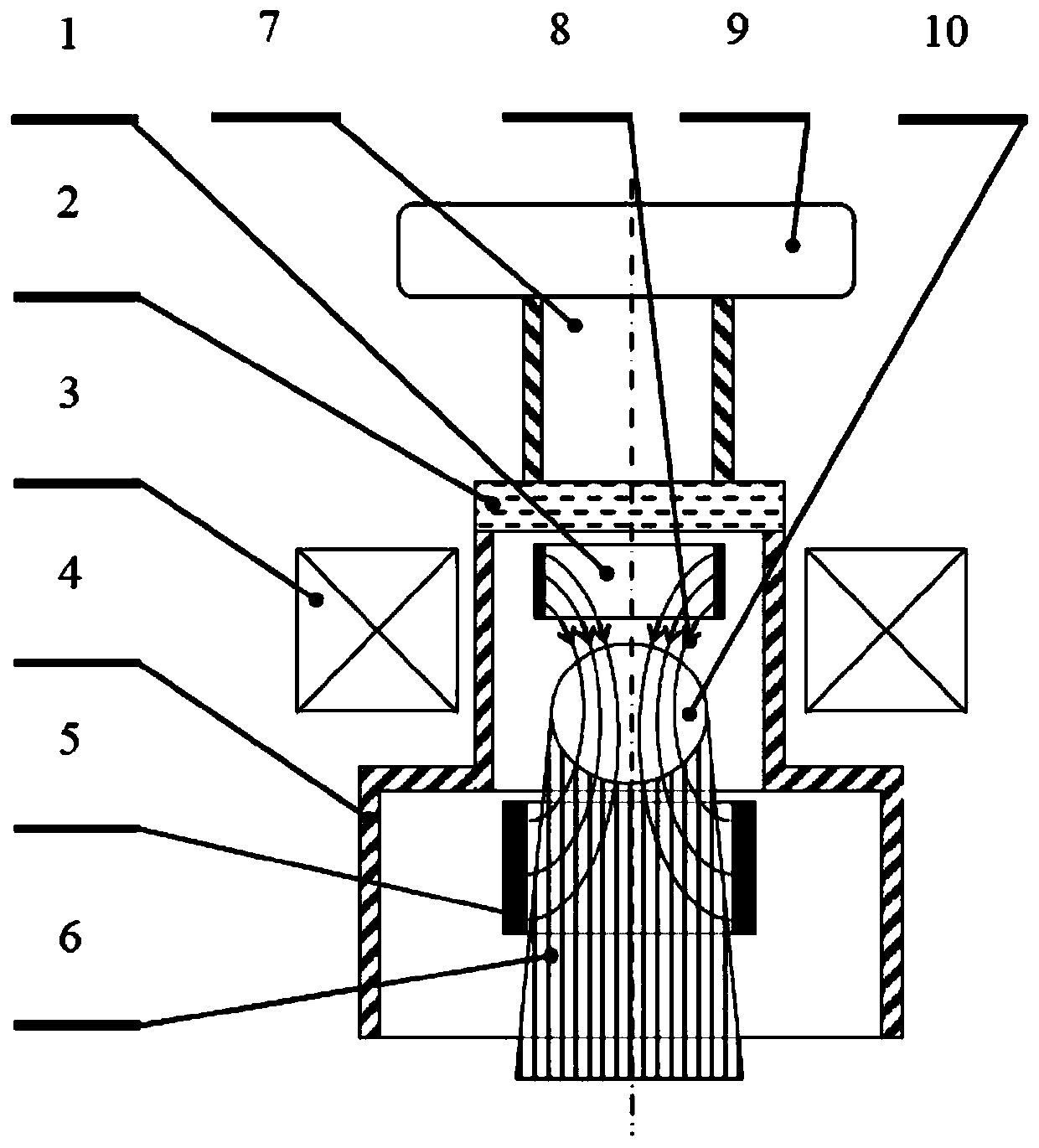

Image

Examples

Embodiment 1

[0020] On the basis of the existing ECR plasma source, the additional hot cathode 5 is made of tungsten wire, made into a solenoid shape, and placed above the resonance area. The anode 1 is made of molybdenum sheet, made into a cylindrical shape, and placed close to the lower edge of the resonance area. A voltage of 100V is applied between the cathode and the anode, and the hot cathode 5 is heated to the common electron emission temperature of tungsten, 2400°C, by means of self-electric heating, and a gas of 50Pa is introduced into the vacuum chamber. The highest plasma beam density that can be achieved by this ECR plasma source is 5×10 21 / m 2

Embodiment 2

[0022] On the basis of the existing ECR plasma source, the additional hot cathode 5 is made of lanthanum hexaboride, made into a cylindrical shape, and placed under the resonance area. The anode 1 copper plate is made into the same shape as the section of the waveguide and placed above the resonance area. A voltage of 200V is applied between the cathode and the anode, and the hot cathode 5 is heated to the common electron emission temperature of lanthanum hexaboride, which is 1500°C, by means of infrared baking heating, and a gas of 1.0Pa is introduced into the vacuum chamber. The highest plasma beam density that can be achieved by this ECR plasma source is 2×10 22 / m 2

Embodiment 3

[0024] On the basis of the existing ECR plasma source, the additional hot cathode 5 is made of a rare earth tungsten alloy sheet, made into a cylindrical shape, and placed close to the lower edge of the resonance area. The anode 1 is made of a stainless steel sheet, made into a cylindrical shape, and placed on the upper edge of the resonance area. A voltage of 20V is applied between the cathode and the anode, and the hot cathode 5 is heated to the common electron emission temperature of rare earth tungsten at 2000°C by means of high-frequency heating, and a gas of 0.01Pa is introduced into the vacuum chamber. The highest plasma beam density achievable by this ECR plasma source is 8×10 21 / m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com