Segmented copolymer capable of spontaneously constructing specific nanostructure in epoxy resin and application of segmented copolymer to high performance modification of epoxy resin

A technology of block copolymer and epoxy resin, which is applied in the direction of epoxy resin glue, epoxy resin coating, adhesive type, etc., can solve the problem of high crosslinking density of cured products, insufficient toughness of EP cured products, and large internal stress And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

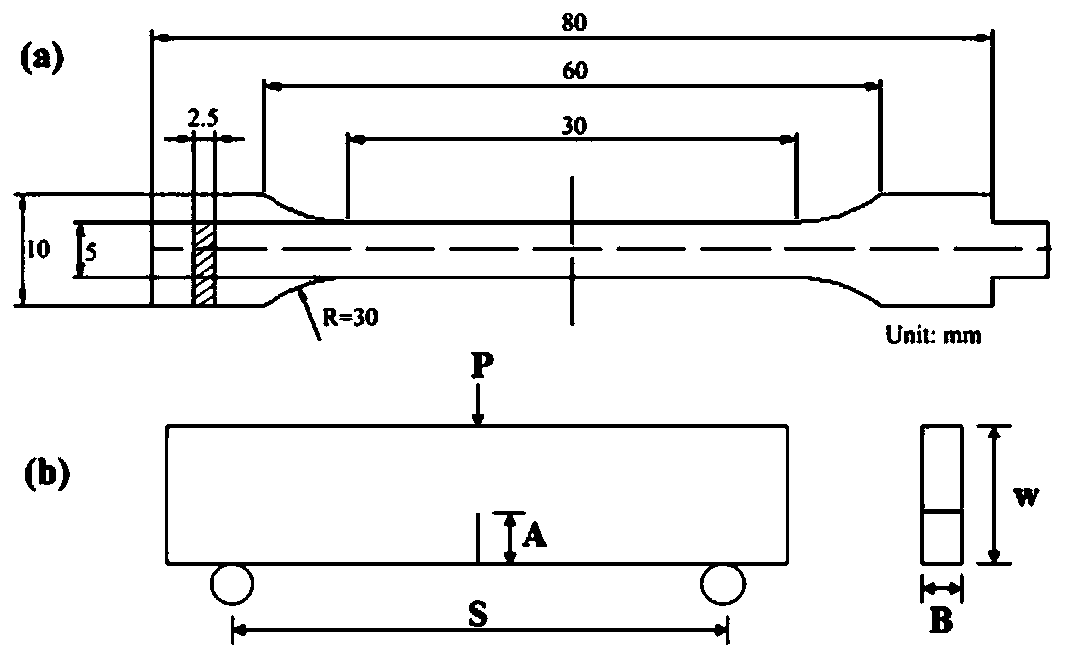

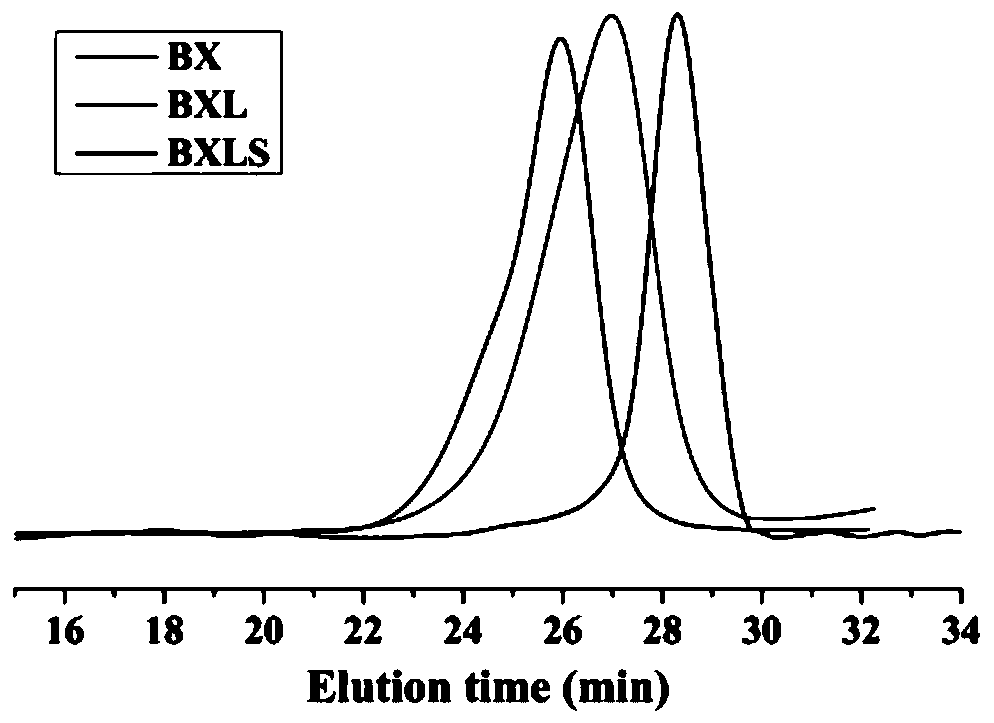

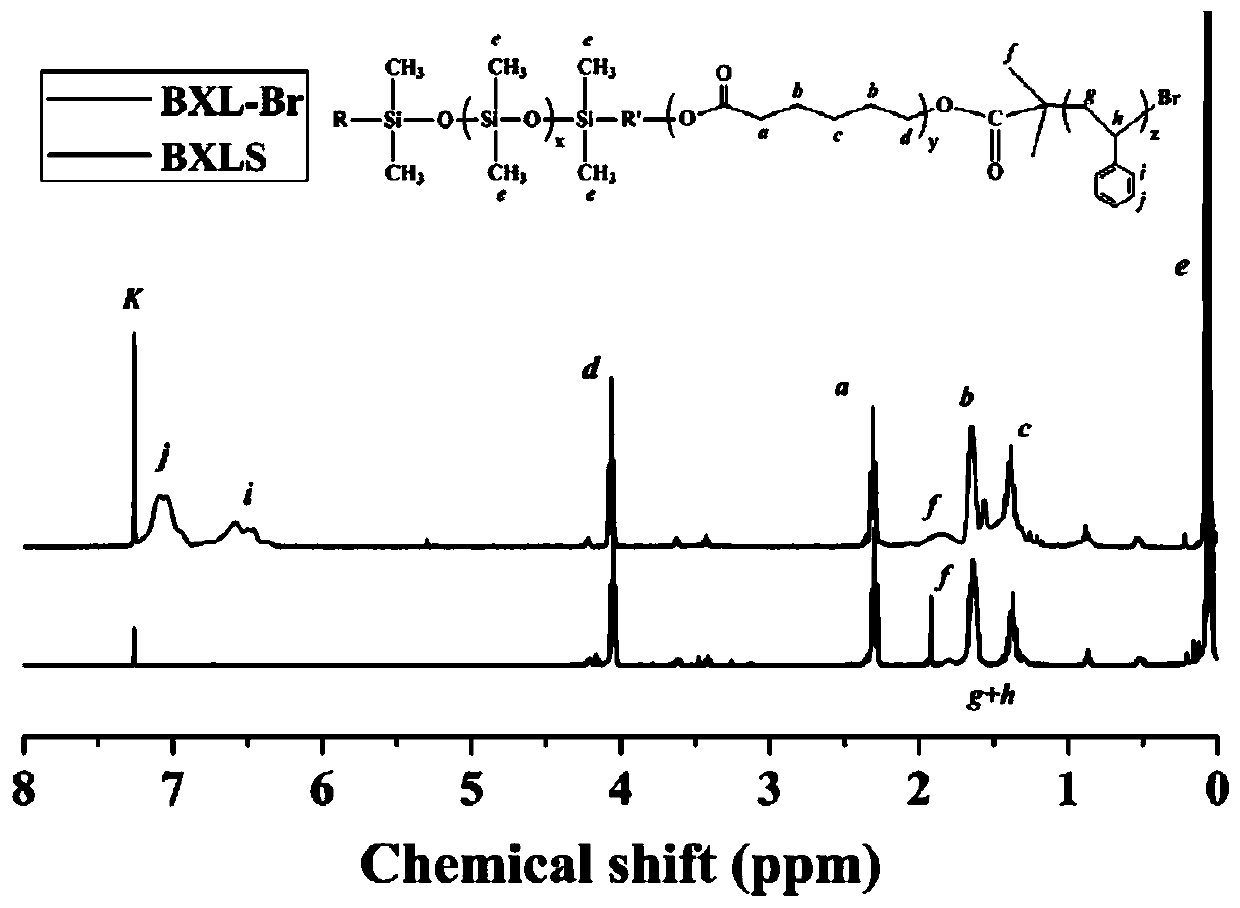

[0038] Embodiment 1, preparation and performance detection of composite material of the present invention

[0039] One, the preparation of composite material of the present invention

[0040] 1 Experimental materials and reagents

[0041] BX-OH: polydimethylsiloxane, Japan Shin-Etsu Chemical Co., Ltd., product number X-22-107BX (R and R' in the structural formula are short hydrocarbon chain end units, for example: butyl (R-: CH 3 -CH 2 -CH 2 -CH 2 -), ethyl (-R'-: -CH 2 -CH 2 -), but the manufacturer did not give a specific structural formula). Caprolactone, polystyrene, dibromoisobutyryl bromide, and stannous octoate were all chemically pure and were purchased from Shanghai Aladdin Biochemical Technology Co., Ltd. EP: bisphenol A epoxy resin (E51), Phoenix brand epoxy resin, model WSR618 (E51), Nantong Xingcheng Material Co., Ltd. Chromaticity: ≤40Pt-Co, epoxy equivalent: 184~195g / mol, hydrolyzed chlorine: ≤0.2%, 50mg / kg, volatile matter: 0.5%, viscosity (25°C): 10000...

Embodiment 2

[0084]The BXLS / EP composite material prepared in Example 1 is used as the matrix resin, and the commonly used modifiers in the fields of coatings, electrical materials, casting packaging materials, adhesives, sealants, etc. are prepared to prepare coatings, electrical materials, casting packaging materials, etc. Materials, adhesives, sealants.

[0085] In summary, the BXLS block copolymer forms a novel nanostructure of the "paramecium" shape in the epoxy resin, which makes the BXLS / epoxy resin composite material prepared by the present invention have an extremely low addition amount of the BXLS block copolymer. Under the circumstances, the toughness of the material is significantly increased and it also has more excellent mechanical properties, which greatly broadens the application field of epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com