Scandium-based rare earth luminescence material and preparation method thereof

A technology of rare earth luminescence and scandium salt, applied in luminescent materials, chemical instruments and methods, inks, etc., can solve the problems of luminous intensity quenching and low luminous intensity, achieve increased asymmetry, simple preparation method, and good reversibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

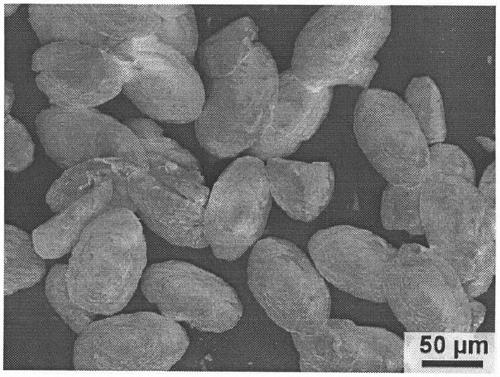

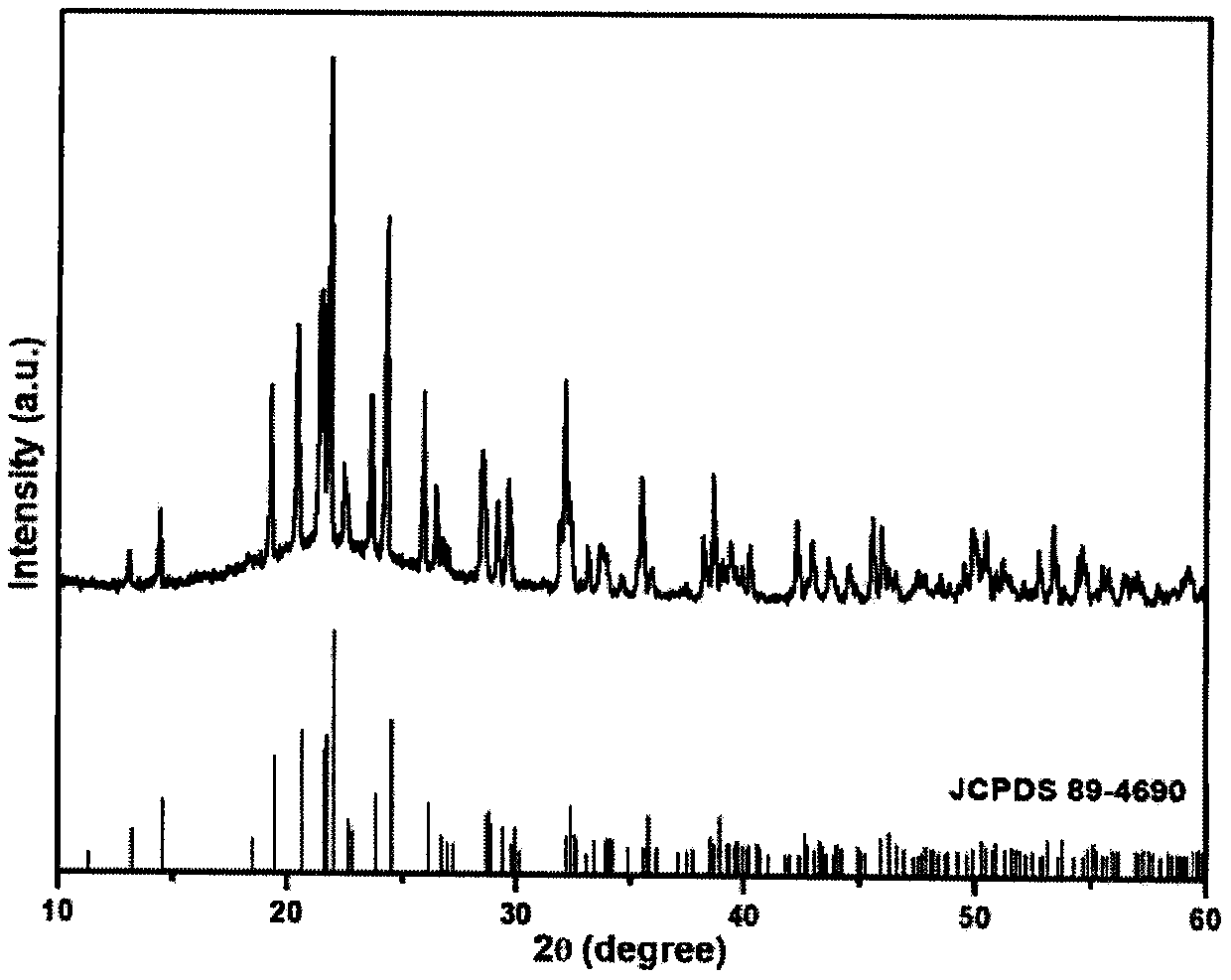

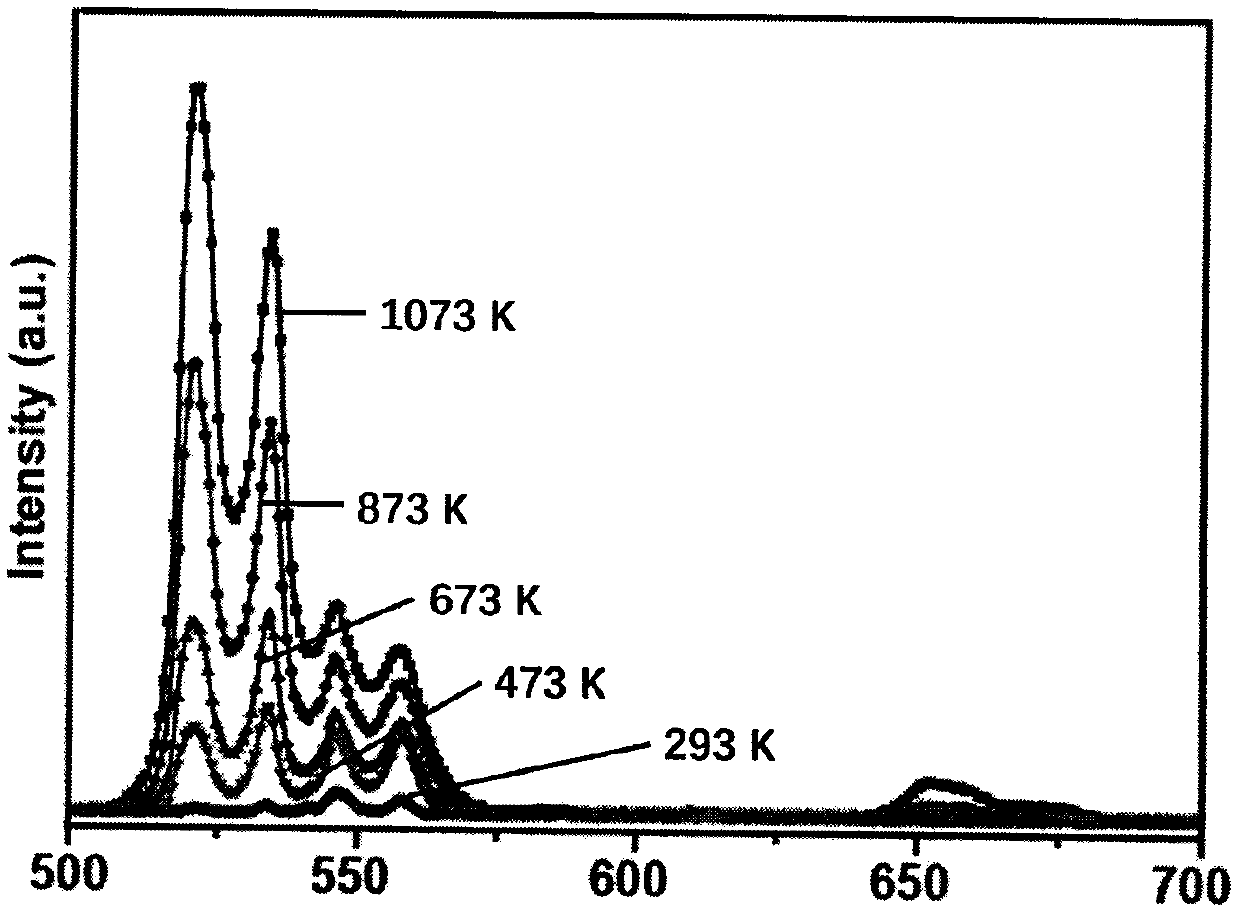

[0042] 0.64mmol (0.1660g) of ScCl 3 ·6H 2 O, 0.144 mmol (0.0558 g) of YbCl 3 ·6H 2 O and 0.016mmol (0.0042g) ErCl 3 Add 15 mL of deionized water, stir vigorously for 15 minutes, add 0.1 g of polyvinylpyrrolidone, continue stirring for 30 minutes, and then add 1.2 mmol (0.3958 g) of Na 2 WO 4 2H 2 O, stir, adjust the pH to 5 with 3mol / L HCl, continue to stir for 30 minutes, then transfer all the white solution to a 25mL polytetrafluoroethylene reactor, put it into an oven, and react at 180°C for 12 hours. After the reaction was completed, the obtained white precipitate was centrifuged three times with deionized water. Dry at 70°C for 6 hours to obtain a white powder, then put it into a muffle furnace and anneal at 800°C for 2 hours to obtain Sc 2 (WO 4 ) 3 : Yb / Er white powder, wherein, the doping mole fraction of Yb is 18%, and the mole fraction of Er doping is 2%. The scanning electron microscope photo of the obtained powder is shown in figure 1 , X-ray diffraction...

Embodiment 2

[0044] 0.3mmol (0.0693g) of Sc(NO 3 ) 3 , 0.04mmol (0.0144g) of Yb (NO 3 ) 3 and 0.06mmol (0.0212g) Er (NO 3 ) 3 Add 15 mL of deionized water, stir vigorously for 15 minutes, add 0.3 g of polyvinylpyrrolidone, continue stirring for 30 minutes, then add 0.6 mmol (0.157 g) of Li 2 WO 4 , stirring, with 3mol / L of H 2 SO 4 Adjust the pH to 5, continue to stir for 30 minutes, then transfer all the white solution to a 25mL polytetrafluoroethylene reactor, and put it in an oven at 160°C for 35 hours. After the reaction was completed, the obtained white precipitate was centrifuged three times with deionized water. Dry at 70°C for 6 hours to obtain a white powder and put it into a muffle furnace for annealing at 400°C for 5 hours to obtain Sc 2 (WO 4 ) 3 : Yb / Er white powder, wherein the mole fraction of Yb doped is 1%, and the mole fraction of Er doped is 15%.

Embodiment 3

[0046] 0.432mmol (0.0959g) of Sc(CH 3 COO) 3 , 0.12mmol (0.0507g) of Yb(CH 3 COO) 3 and 0.048mmol (0.02g) Er (CH 3 COO) 3 Add 15 mL of deionized water, stir vigorously for 15 minutes, add 1 g of polyvinylpyrrolidone, continue stirring for 30 minutes, and then add 0.9 mmol (0.2934 g) of K 2 WO 4 , stirred, with 3mol / L HNO 3 Adjust pH to 5. Stirring was continued for 30 minutes, and then all the white solution was transferred to a 25mL polytetrafluoroethylene reactor, and placed in an oven at 220°C for 6 hours. After the reaction was completed, the obtained white precipitate was centrifuged three times with deionized water. Dry at 70°C for 6 hours to obtain a white powder and put it into a muffle furnace for 12 hours at 500°C to obtain Sc 2 (WO 4 ) 3 : Yb / Er white powder, wherein the Yb doped mole fraction is 20%, and the Er doped mole fraction is 8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com