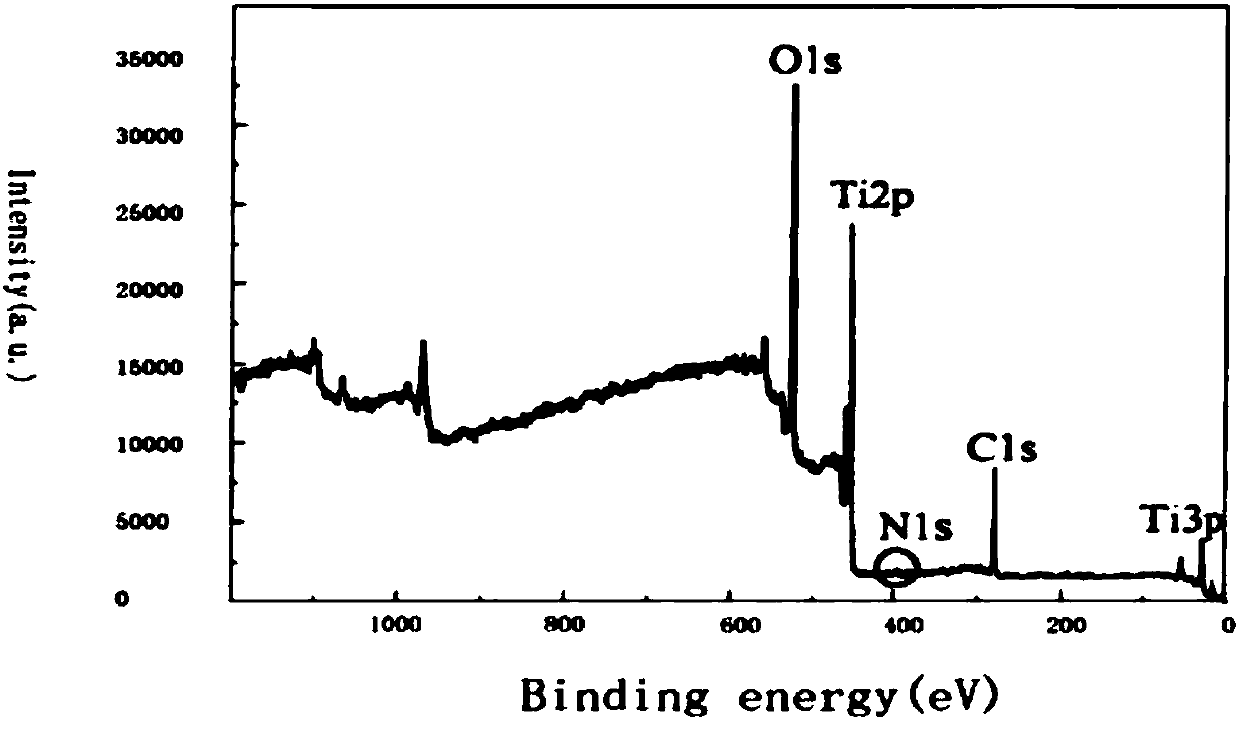

Preparation method of double-doped rutile TiO2 nanorods

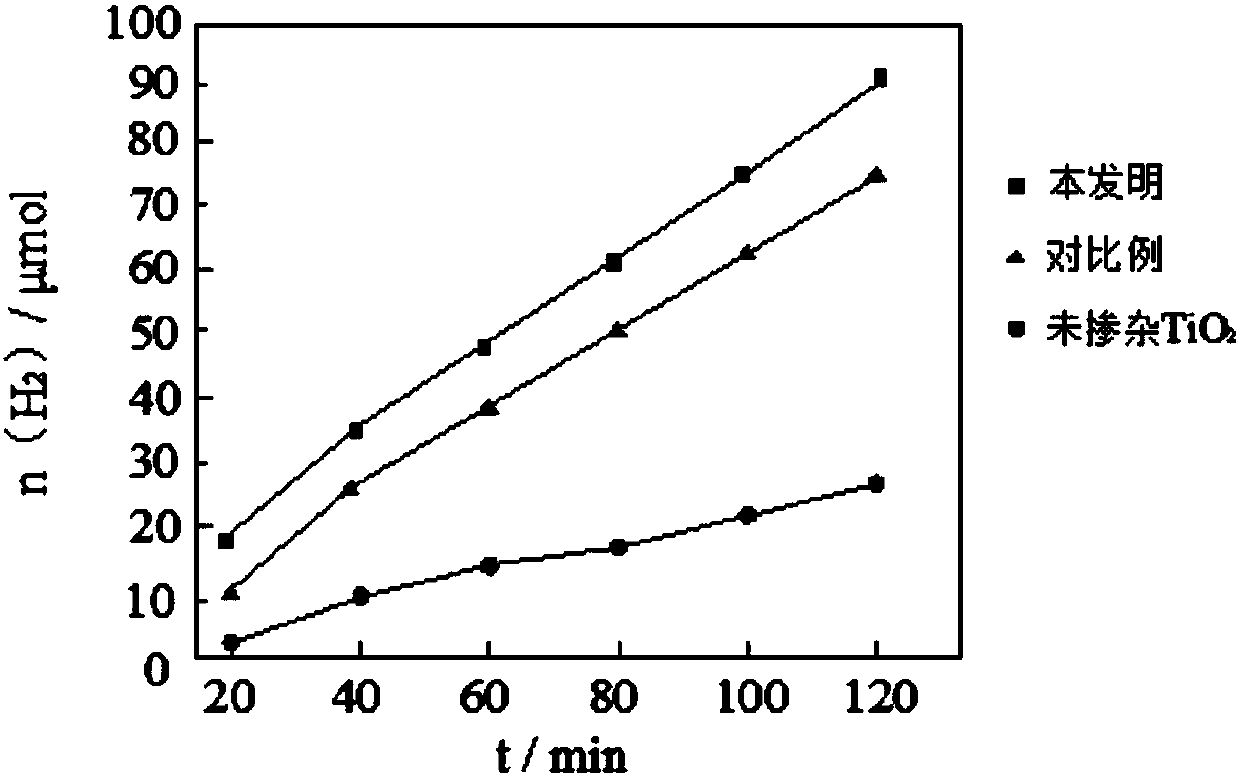

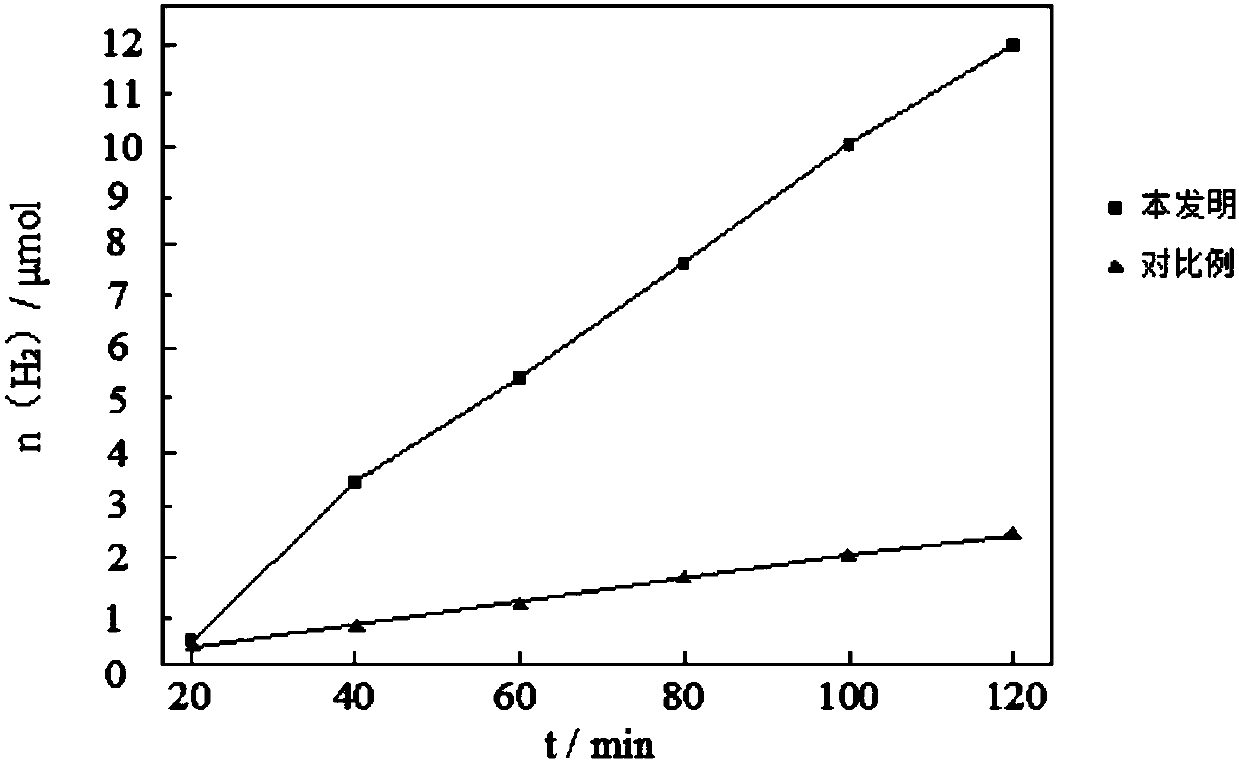

A rutile phase, nanorod technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of limiting the application of TiO2, ineffective absorption of visible light, etc., to achieve the effect of improving the mobility of the electrons and increasing the lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 0.06g of titanium carbide, ultrasonically disperse it into 16mL of distilled water, add 4mL of ethylenediamine, disperse for 30 minutes, put it into a 50mL hydrothermal reaction kettle, set the temperature at 180°C for 6 hours, then take it out and let it cool naturally to 20°C, pour it into a centrifuge tube for centrifugation, pickle twice with 2% dilute hydrochloric acid, wash three times with absolute ethanol and distilled water, and dry in a constant temperature drying oven at a temperature of 70°C for 12 hours to obtain the product . Natural cooling to 20°C before subsequent operations, temperature control and cooling methods can enhance the synergistic effect of C and N double doping, making C and N doped into the lattice of titanium oxide, which enhances the response of titanium oxide to visible light. Further improve the catalytic degradation ability.

Embodiment 2

[0028] Weigh 0.12g of titanium carbide, ultrasonically disperse it into 17mL of distilled water, add 5mL of ethylenediamine, disperse for 30 minutes, put it into a 50mL hydrothermal reaction kettle, set the temperature at 180°C for 6 hours, then take it out and let it cool naturally to 20°C, pour it into a centrifuge tube for centrifugation, pickle twice with 2% dilute hydrochloric acid, wash three times with absolute ethanol and distilled water, and dry in a constant temperature drying oven at a temperature of 70°C for 12 hours to obtain the product .

Embodiment 3

[0030] Weigh 0.18g of titanium carbide, ultrasonically disperse it into 18mL of distilled water, add 6mL of ethylenediamine, disperse for 30min, put it into a 50mL hydrothermal reaction kettle, set the temperature at 180°C for 6 hours, then take it out and let it cool naturally to 20°C, pour it into a centrifuge tube for centrifugation, pickle twice with 2% dilute hydrochloric acid, wash three times with absolute ethanol and distilled water, and dry in a constant temperature drying oven at a temperature of 70°C for 12 hours to obtain the product .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com