Preparation method and production device for ultrahigh forcefully coated fishline

A production device and fishing line technology, which are applied in fishing line, textile material processing, textile and papermaking, etc., can solve the problems of weak tensile performance and influence on tensile performance, and achieve high production efficiency, high processing efficiency, and product quality. Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

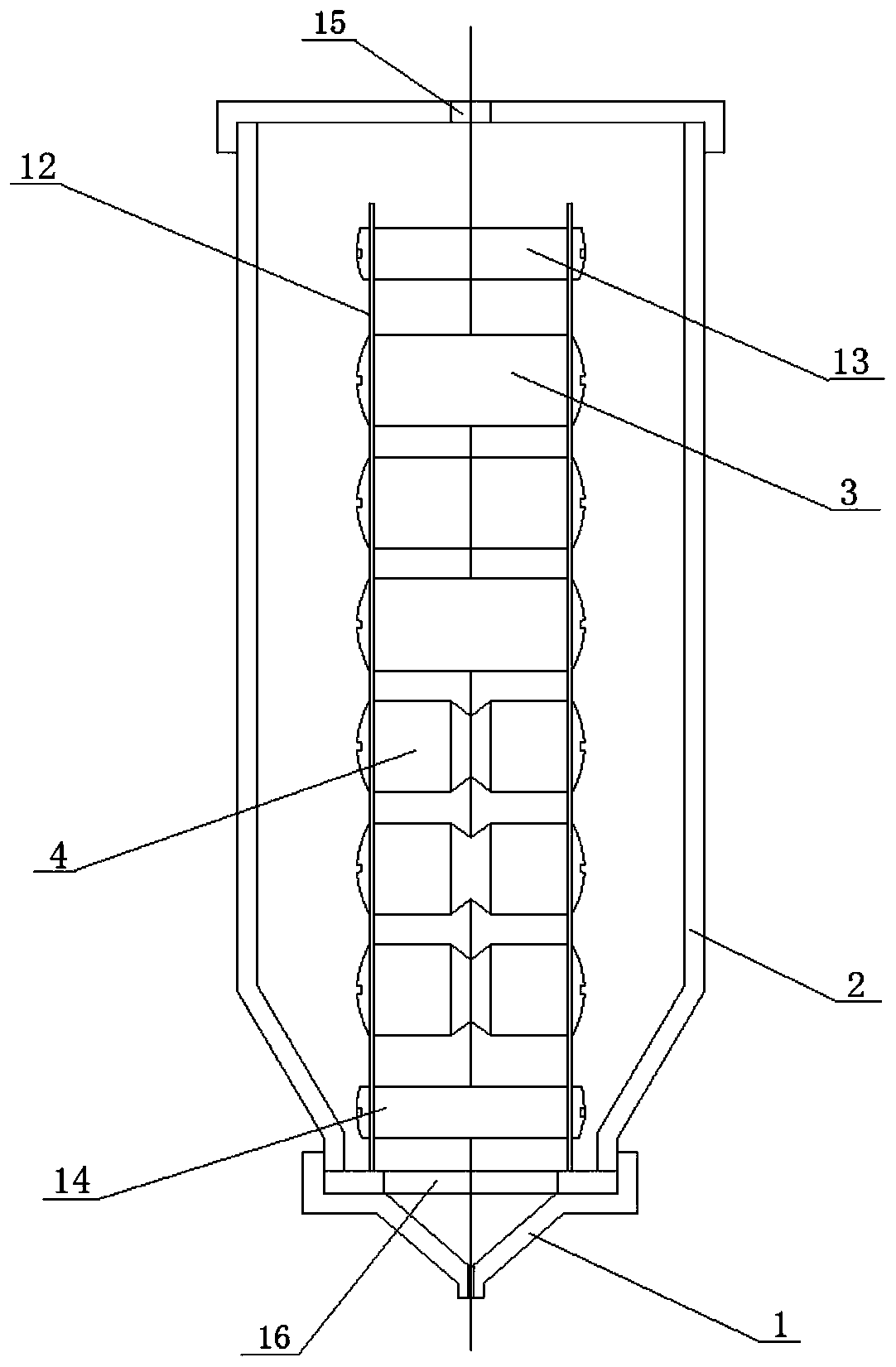

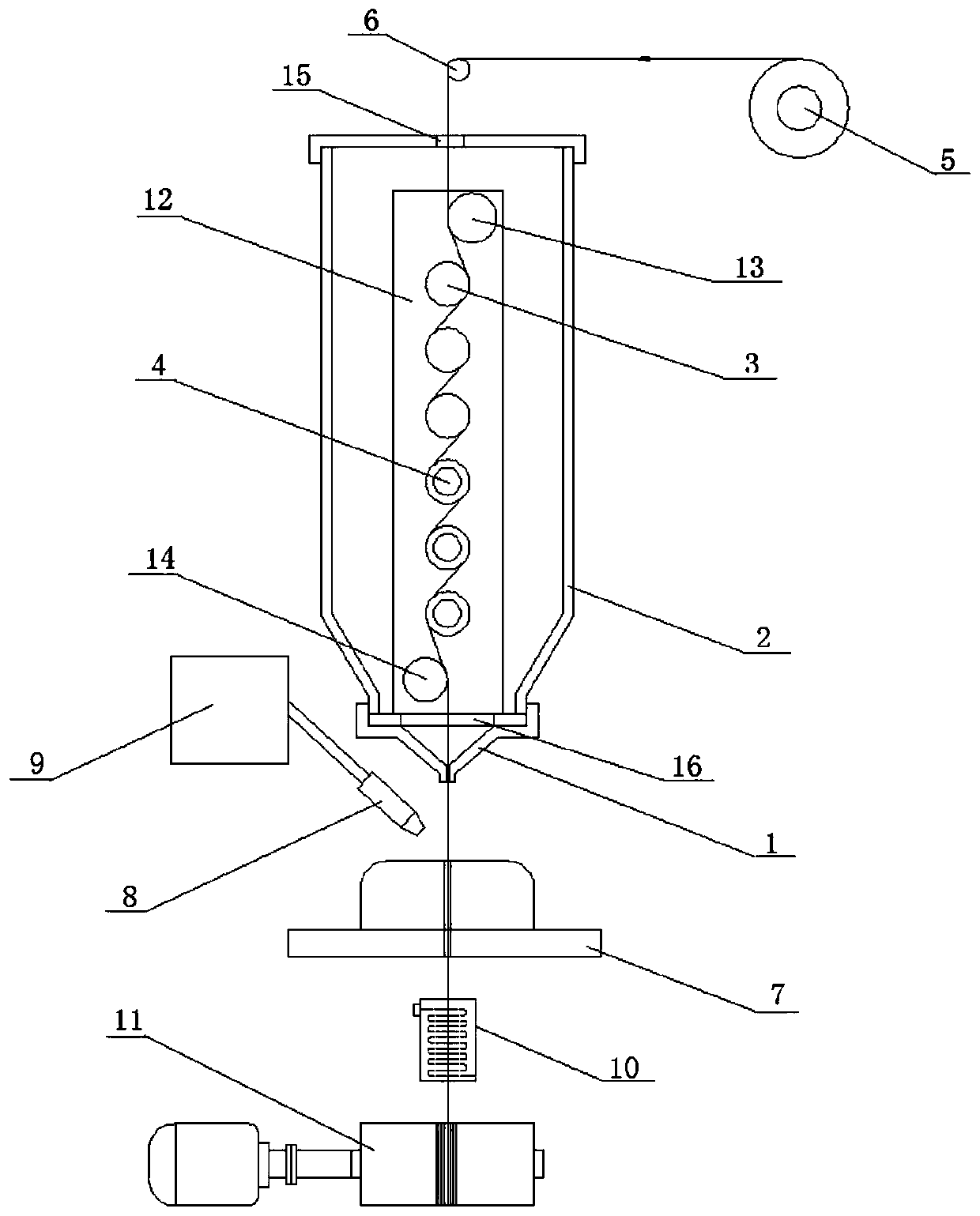

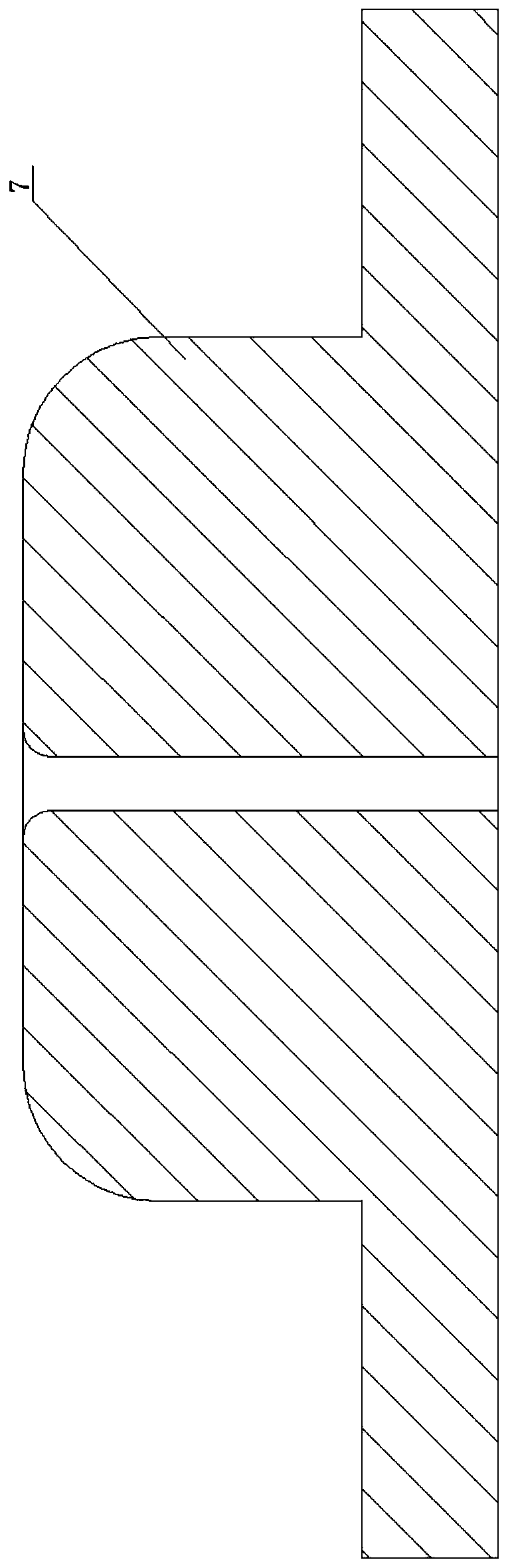

[0036] Example 1, refer to figure 1 and figure 2 , a production device for fishing line, including a rigid line forming device 7, a core wire feeding system and a coating device for fishing line production, the rigid line forming device 7 is fixedly arranged below the preform extrusion hole, refer to image 3 , the rigid wire forming device 7 is provided with a shaping extrusion hole, the shaping extrusion hole is located directly below the pre-forming extrusion hole, and the axis of the shaping extrusion hole is collinear with the axis of the pre-forming extrusion hole; the multifilament core wire It is extruded into the required shape during the process of passing through the shaping extrusion hole. The rigid wire former can be provided with a number of shaped extrusion holes of different diameters to accommodate multifilament core wires of different sizes.

[0037] The coating device for fishing line production includes a coating extrusion mechanism and a multifilament e...

Embodiment 2

[0042] Embodiment 2, in the production device of a fishing line described in Embodiment 1: the core wire feeding system can be arranged above the side of the coating tank 3; the core wire feeding system includes a core wire reel 5 , a wire roll 6 is provided between the core wire reel 5 and the coating tank 2, refer to Figure 4 , the wire roller 6 is provided with an annular wire groove, and the multifilament core wire enters the coating tank from a fixed position under the limit of the annular wire groove. A hot air dryer 10 is also provided between the rigid wire former 7 and the winder 11 , and the hot air dryer 10 is provided with a drying channel for the fishing line to pass through. A coloring spray gun 8 is also provided between the coating tank 2 and the rigid wire former 7, and the coloring spray gun 8 is arranged facing the wire channel formed between the coating tank 2 and the rigid wire former 7, and the coloring The spray gun 8 is connected 9 to a matching paint...

Embodiment 3

[0043] Example 3, in the production device of a fishing line described in Example 1 or 2: the number of pressing rollers 3 can be set to 10, and the number of the forming rollers 4 and the pressing rollers 3 is the same; The interval provided between the squeezing rolls 3 was set to 4 mm, and the distance provided between the adjacent forming rolls 4 was set to 4 mm. The fixing bracket includes two vertically arranged mounting plates 12, the two mounting plates 12 are parallel to each other, and the two mounting plates 12 are respectively fixedly connected to the bottom of the coating tank 2 on both sides of the outlet hole, the extrusion roller 3 and the Both ends of the forming roller 4 are fixedly mounted on the mounting plates 12 on both sides respectively;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com