Preparation method of bletilla striata polysaccharide composite cytoskeleton

A technology of bletilla striata polysaccharides and cell scaffolds, applied in medical science, prostheses, etc., can solve the problems of uncontrollable pore structure of cell scaffolds and affect applications, and achieve good market prospects, good biocompatibility, and excellent network mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

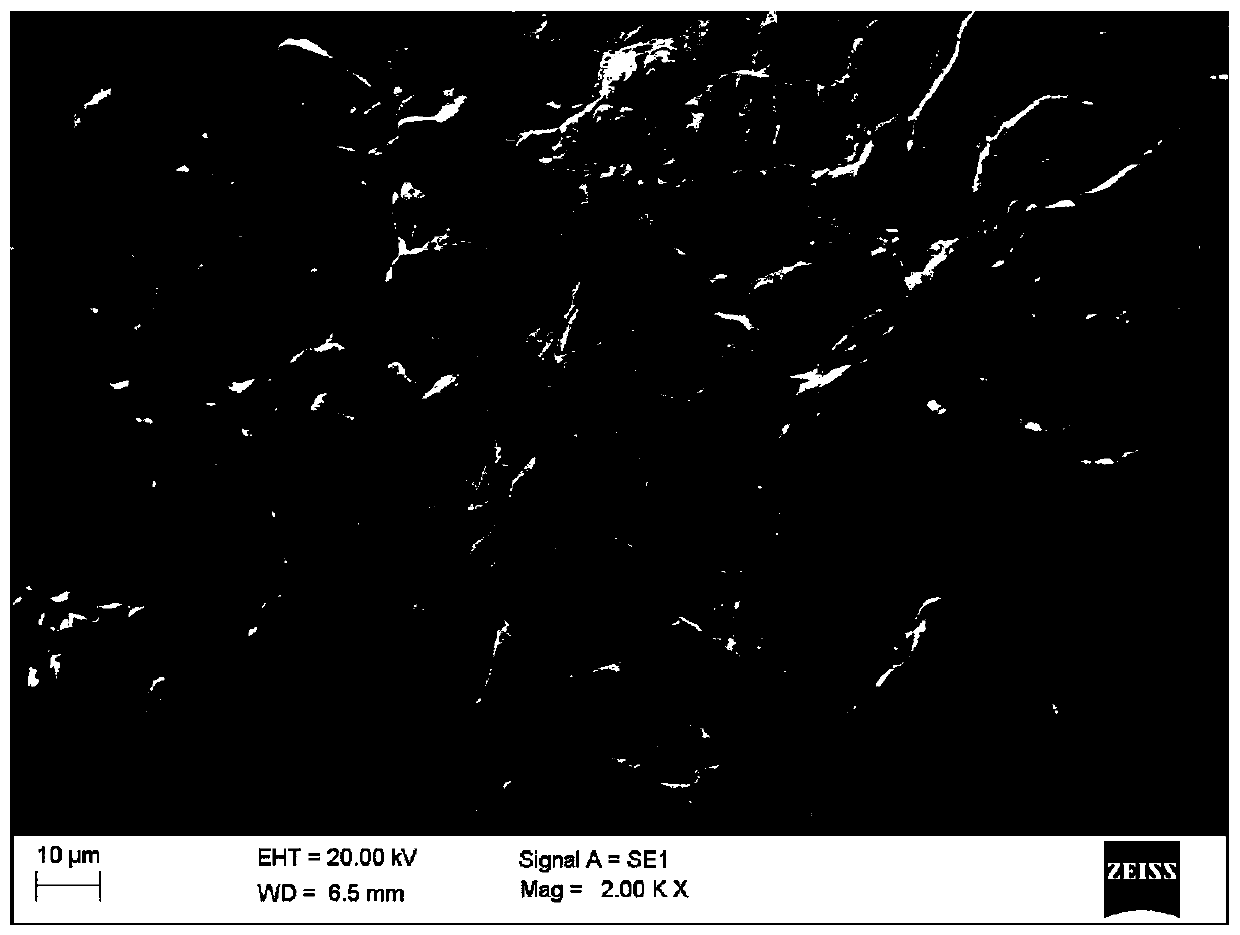

Image

Examples

Embodiment 1

[0027] A method for preparing a bletilla striata polysaccharide composite cell scaffold, comprising the following steps:

[0028] Step 1. Put the tubers of Bletilla striata into the freezer, control the temperature between -15°C, and freeze for 4 hours; crush the tubers of Bletilla striata, the temperature is between -15°C and the pressure is controlled at 0.1MPa to obtain Bletilla striata powder; use a cyclone The collector collects the Bletilla striata powder under negative pressure; the Bletilla striata powder is dried by spray drying, and then passed through a 80-mesh sieve to obtain the Bletilla striata powder; in parts by weight, 20 parts of Bletilla striata powder is added to 800 parts of distilled water, at 100°C Stir at 500r / min for 60min for the first extraction, centrifuge at 3000r / min for 10min, collect the supernatant, add the solid residue to 600 parts of distilled water, and stir at 500r / min for 60min at 100°C for the second extraction. Centrifuge at 3000r / min f...

Embodiment 2

[0033] A method for preparing a bletilla striata polysaccharide composite cell scaffold, characterized in that it comprises the following steps:

[0034] Step 1. Put the tubers of Bletilla striata into the freezer, control the temperature between -20°C, and freeze for 6 hours; crush the tubers of Bletilla striata, the temperature is between -20°C and the pressure is controlled at 0.3MPa to obtain Bletilla striata powder; use a cyclone The collector collects the Bletilla striata powder under negative pressure; the Bletilla striata powder is dried by spray drying, and then passed through an 80-mesh sieve to obtain the Bletilla striata powder; in parts by weight, take 15 parts of Bletilla striata powder and add 800 parts of distilled water, at 100°C Stir at 500r / min for 60min for the first extraction, centrifuge at 3000r / min for 10min, collect the supernatant, add the solid residue to 650 parts of distilled water, and stir at 500r / min for 60min at 100°C for the second extraction. ...

Embodiment 3

[0039] A method for preparing a bletilla striata polysaccharide composite cell scaffold, comprising the following steps:

[0040] Step 1. Put the tubers of Bletilla striata into the freezer, control the temperature between -15°C, and freeze for 4 hours; crush the tubers of Bletilla striata, the temperature is between -15°C and the pressure is controlled at 0.1MPa to obtain Bletilla striata powder; use a cyclone The collector collects the Bletilla striata powder under negative pressure; the Bletilla striata powder is dried by spray drying, and then passed through a 80-mesh sieve to obtain the Bletilla striata powder; in parts by weight, 20 parts of Bletilla striata powder is added to 800 parts of distilled water, at 100°C Stir at 500r / min for 60min for the first extraction, centrifuge at 3000r / min for 10min, collect the supernatant, add the solid residue to 600 parts of distilled water, and stir at 500r / min for 60min at 100°C for the second extraction. Centrifuge at 3000r / min f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com