Preparation method of composite mesoporous adsorbent material and application thereof

A composite mesoporous and mesoporous carbon technology, which is applied in the preparation of composite mesoporous structure adsorbent materials, the preparation of adsorbent materials, and the adsorption of organic volatile gases. It can solve the problems of different sizes of gas molecules, high material costs, Problems such as expensive template agent, to achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

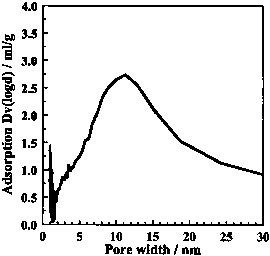

Image

Examples

Embodiment 1

[0028] First, weigh 2.0g of P123 template, add 120mL of 0.8M hydrochloric acid solution to it, and then stir thoroughly to form a colorless and transparent solution, then add 8.6mL of TEOS dropwise to it, and stir After 24h, add 1mL of tellurium nanowires with a diameter of 20nm to it, continue stirring for 1h, transfer the mixed solution to a hydrothermal crystallization kettle, and crystallize at 120°C for 18h; after the reaction, centrifuge, wash and dry dry product, and then calcined at 750°C for 5 hours to obtain a composite mesoporous molecular sieve;

[0029] Next, get the concentrated sulfuric acid of 0.18g, the glucose of 1.25g and the deionized water of 5g, after mixing uniformly, then add 1g of above-mentioned prepared composite mesoporous molecular sieves to it to obtain white suspension, then transfer the white suspension to Put it into a pressure vessel to pressurize to 1.2bar, and keep it under this pressure for 8h;

[0030] Again, heat-treat the molecular siev...

Embodiment 2

[0033] First, weigh 2.0g of P123 template, add 120mL of 0.8M hydrochloric acid solution to it, and then stir thoroughly to form a colorless and transparent solution, then add 8.6mL of TEOS dropwise to it, and stir After 24h, add 1mL of tellurium nanowires with a diameter of 40nm to it, continue stirring for 1h, transfer the mixed solution to a hydrothermal crystallization kettle, and crystallize at 120°C for 18h; after the reaction, centrifuge, wash and dry dry product, and then calcined at 750°C for 5 hours to obtain a composite mesoporous molecular sieve;

[0034] Next, get the concentrated sulfuric acid of 0.18g, the glucose of 1.25g and the deionized water of 5g, after mixing uniformly, then add 1g of above-mentioned prepared composite mesoporous molecular sieves to it to obtain white suspension, then transfer the white suspension to Put it into a pressure vessel and pressurize to 1.6bar, and keep it under this pressure for 8h;

[0035] Again, heat-treat the molecular sie...

Embodiment 3

[0038]First, weigh 2.0g of P123 template, add 120mL of 0.8M hydrochloric acid solution to it, and then stir thoroughly to form a colorless and transparent solution, then add 8.6mL of TEOS dropwise to it, and stir After 24h, add 1mL of tellurium nanowires with a diameter of 40nm to it, continue stirring for 1h, transfer the mixed solution to a hydrothermal crystallization kettle, and crystallize at 120°C for 18h; after the reaction, centrifuge, wash and dry dry product, and then calcined at 750°C for 5 hours to obtain a composite mesoporous molecular sieve;

[0039] Next, get the concentrated sulfuric acid of 0.18g, the glucose of 1.25g and the deionized water of 5g, after mixing uniformly, then add 1g of above-mentioned prepared composite mesoporous molecular sieves to it to obtain white suspension, then transfer the white suspension to Put it into a pressure vessel and pressurize to 1.6bar, and keep it under this pressure for 8h;

[0040] Again, heat-treat the molecular siev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com