Filter device comprising piezoelectric composite material and its use in adsorption of atmospheric particulate matter

An atmospheric particulate matter and filter device technology, applied in the field of air purification, can solve the problems of easy generation of ozone, consumption of energy, temperature safety problems, etc., and achieve the effects of prolonging the service life, improving the service life, and stably storing electric charges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Wherein, the preparation method of described composite material comprises the steps:

[0044] 1) Prepare a lithium niobate piezoelectric crystal and polarize it in orientation, and prepare particles with a size range between 100nm and 50 μm, that is, the lithium niobate particles after the single domain polarization;

[0045] 2) Uniformly mixing the monodomain polarized lithium niobate particles in step 1) with polymer electret, optionally carbon nanotubes (such as multi-walled carbon nanotubes) through a twin-screw extruder to prepare masterbatch;

[0046] 3) The above prepared masterbatch is prepared into a non-woven fabric by melt spraying or film-forming treatment is prepared into a film.

[0047] In step 1) of the above-mentioned preparation method, the preparation of the lithium niobate particles after the monodomain polarization is specifically:

[0048] The lithium niobate piezoelectric crystal after monodomain orientation is ground into powder by grinding, si...

Embodiment 1

[0062] Embodiment 1 prepares film

[0063] Films were prepared as follows:

[0064] (1) Prepare a lithium niobate (LN) piezoelectric crystal and polarize it in orientation, grind it into powder by grinding, pass the powder through a 300-mesh sieve, and collect the sieved LN powder.

[0065] (2) LN powder mixed with multi-walled carbon nanotubes (CNT) and polypropylene (PP) to prepare a masterbatch

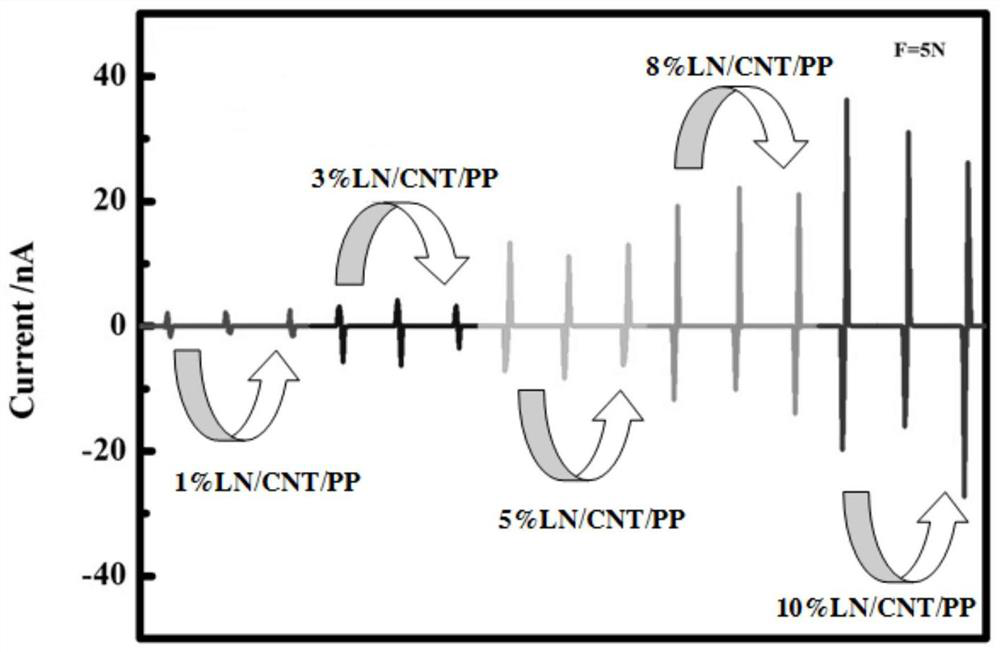

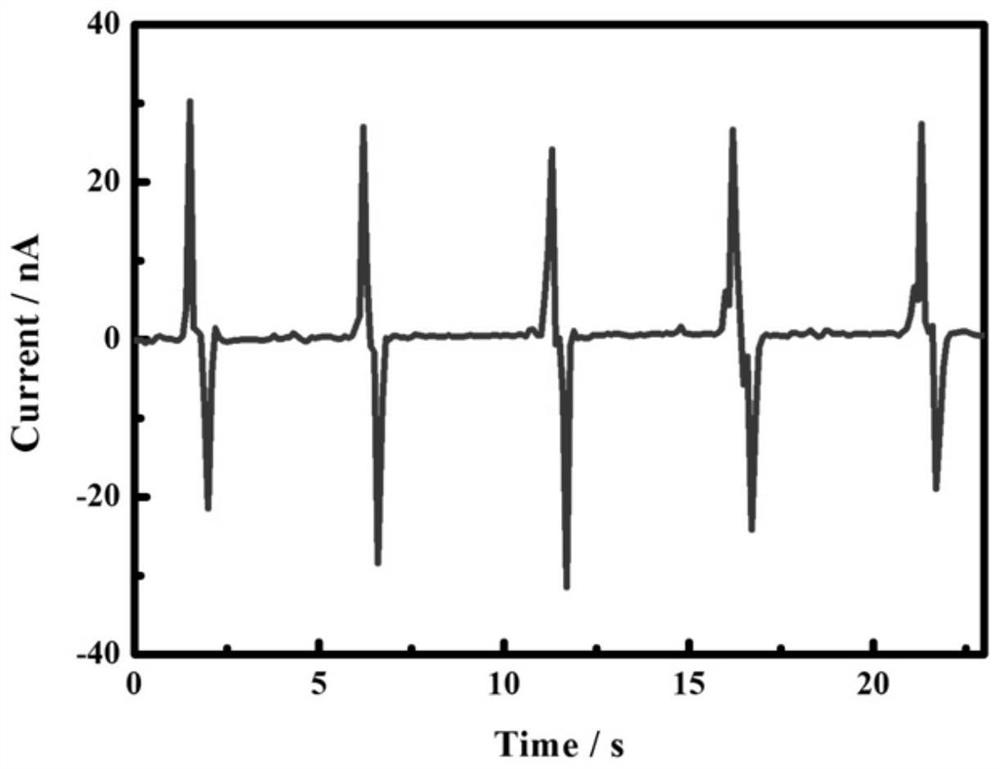

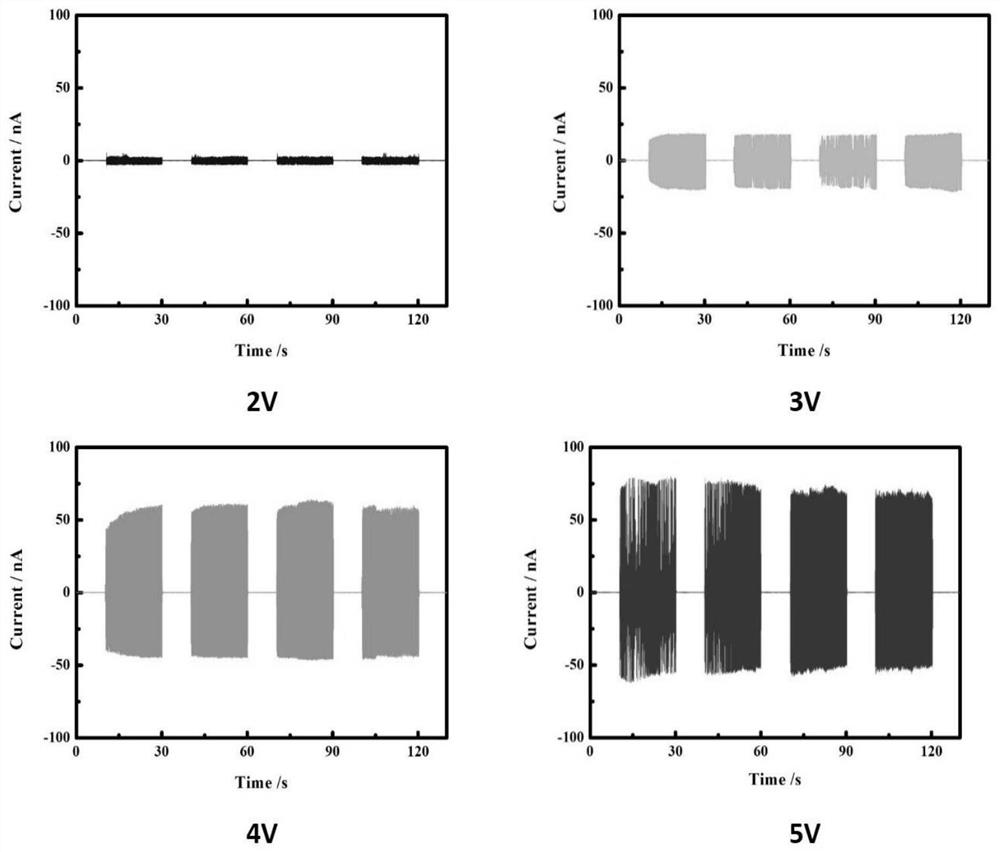

[0066] In a twin-screw extruder, mix PP, CNT (1wt%) and the LN powder obtained in step (1) of different mass ratios (1%, 3%, 5%, 8% and 10%), granulate, Get masterbatch.

[0067] (3) Film forming by hot pressing: melt the masterbatch in step (2) at 200° C., form a film under a pressure of 8 MPa, and obtain a film after cooling; cut the obtained film into a rectangle (2cm×3cm) for later use.

Embodiment 2

[0068] Embodiment 2 prepares non-woven fabric

[0069] (1) Prepare a lithium niobate (LN) piezoelectric crystal and polarize it in orientation, grind it into powder by grinding, pass the powder through a 300-mesh sieve, and collect the sieved LN powder.

[0070] (2) LN powder mixed with multi-walled carbon nanotubes CNT and PP to prepare masterbatch

[0071] In a twin-screw extruder, mix PP, CNT (1wt%) and the LN powder obtained in step (1) with different mass ratios (1%, 3%, 5%, 8% and 10%), and granulate.

[0072] (3) The masterbatch prepared above is prepared into a non-woven fabric by melt spraying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com