Ethanedithiol modified nano molybdenum disulfide for modifying polysulfide sealant and modification method thereof

A technology of nano molybdenum disulfide and polysulfide sealant, which is applied in the directions of adhesives, adhesive additives, non-polymer adhesive additives, etc. It can improve the mechanical properties and increase the strength of the interface interaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, the preparation of ethanedithiol modified nano molybdenum disulfide

[0028] The molar mass ratio of ethanedithiol and lamellar molybdenum disulfide is 2:1. Add lamellar molybdenum disulfide into deionized water and ultrasonically disperse uniformly to obtain a molybdenum disulfide solution; add ethanedithiol to the molybdenum disulfide solution to ultrasonically disperse uniformly, and then freeze-dry the mixed solution to obtain ethanedithiol-modified Nanomolybdenum disulfide.

[0029] The ethanedithiol-modified nanomolybdenum disulfide prepared in this example is analyzed below, and the lamellar molybdenum disulfide is used as a comparison.

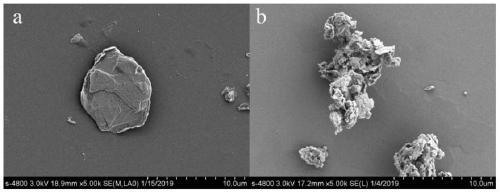

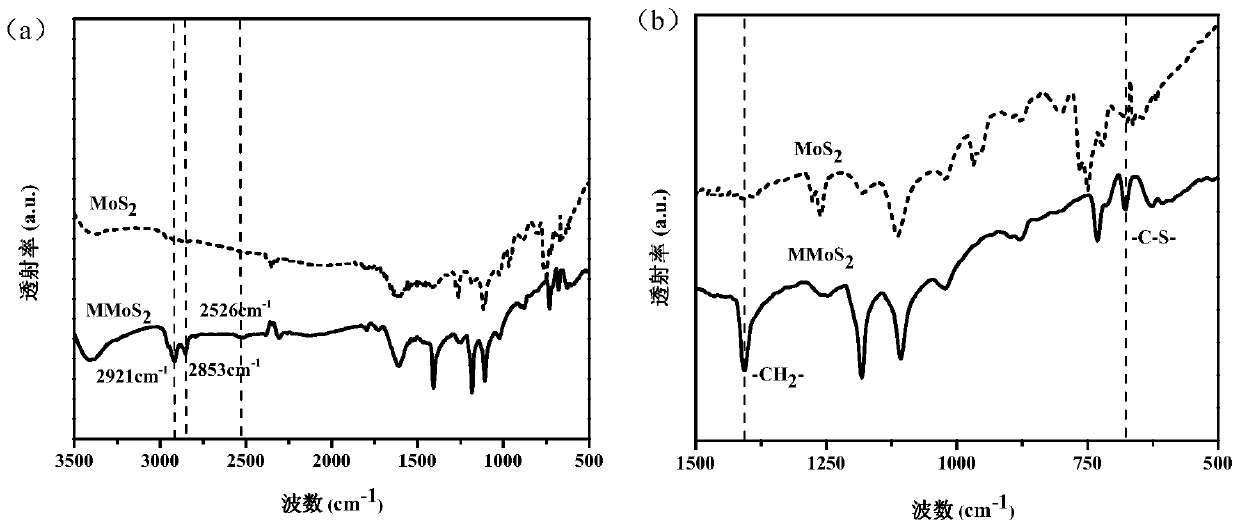

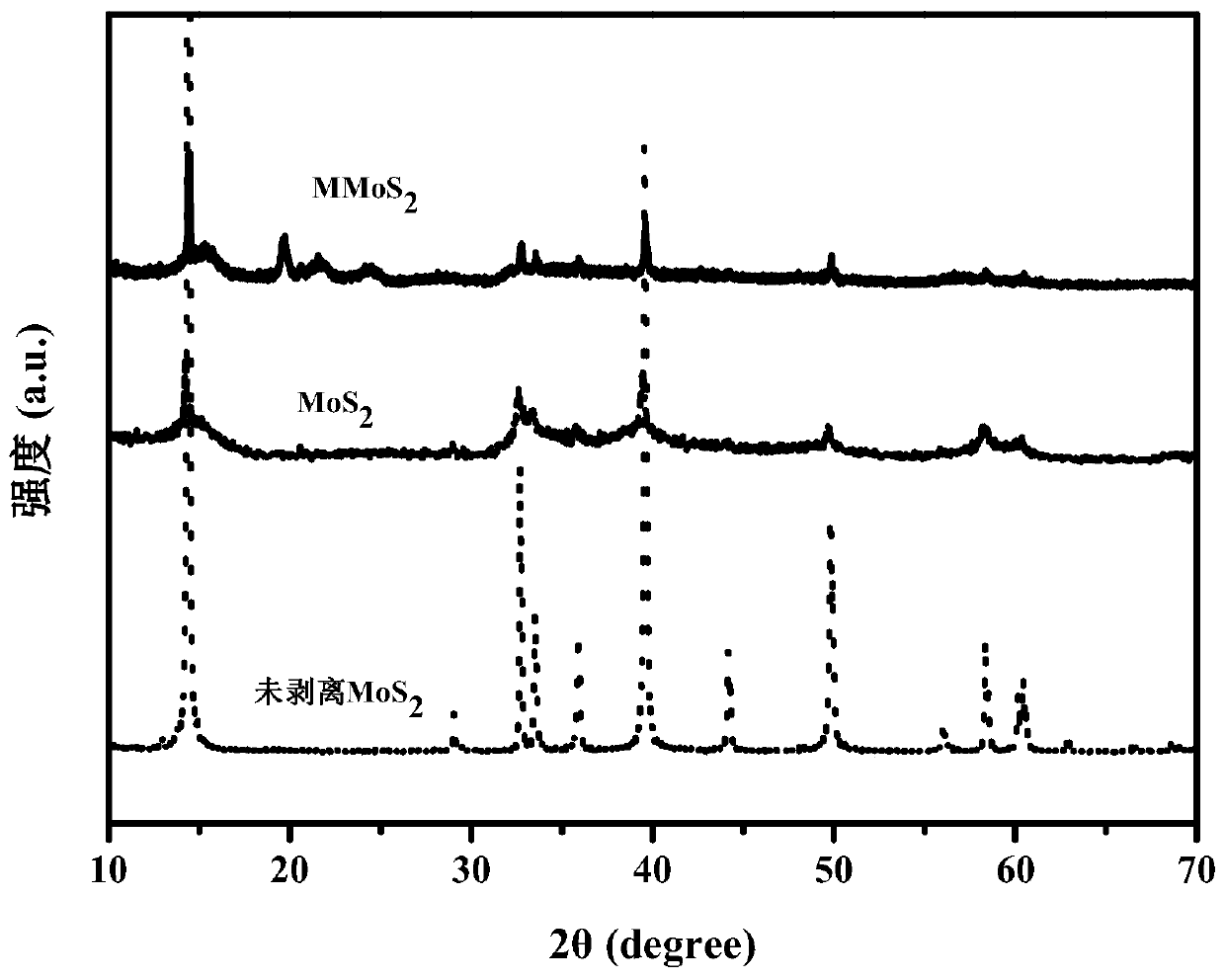

[0030] figure 1 Lamellar molybdenum disulfide (MoS 2 ) and ethanedithiol-modified nanomolybdenum disulfide (MMoS 2 ) scanning electron microscope (SEM). Molybdenum disulfide presents a very thin lamellar structure, indicating that the disulfide was successfully peeled off. The surface of nanomolybdenum disulf...

Embodiment 2

[0034] Example 2, Modification of lamellar molybdenum disulfide and ethanedithiol modified nano molybdenum disulfide to polysulfide sealant

[0035] The ethanedithiol modified nanomolybdenum disulfide used in this example is the sample in Example 1.

[0036] In this embodiment, the polysulfide sealant of the following components is taken as an example to verify the modification effect of the lamellar molybdenum disulfide and ethanedithiol-modified nano-molybdenum disulfide on it:

[0037] Polysulfide sealant is composed of base paste and vulcanization paste in a weight ratio of 10:1.

[0038] The composition of each component by weight in the base paste is:

[0039] Filler: 50 parts of nanometer calcium carbonate;

[0040] Plasticizer: 10 parts of butyl phthalate;

[0041] Silane coupling agent: 0.5 parts of bis-(2-(triethoxysilane) propyl)-tetrasulfide (silane coupling agent KH-69);

[0042] Liquid polysulfide rubber: 100 parts of LP-32 liquid polysulfide rubber (Toray Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com