A kind of ethanedithiol modified nano-molybdenum disulfide for modified polysulfide sealant and its modification method

A technology of nano-molybdenum disulfide and polysulfide sealants, which is applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of modification of the mechanical properties of polysulfide sealants, failure to achieve expected results, failure to Effective dispersion can not be solved to achieve the effect of improving mechanical properties and increasing the strength of interface interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, the preparation of ethanedithiol modified nano molybdenum disulfide

[0028] The molar mass ratio of ethanedithiol and lamellar molybdenum disulfide is 2:1. Add lamellar molybdenum disulfide into deionized water and ultrasonically disperse uniformly to obtain a molybdenum disulfide solution; add ethanedithiol to the molybdenum disulfide solution to ultrasonically disperse uniformly, and then freeze-dry the mixed solution to obtain ethanedithiol-modified Nanomolybdenum disulfide.

[0029] The ethanedithiol-modified nanomolybdenum disulfide prepared in this example is analyzed below, and the lamellar molybdenum disulfide is used as a comparison.

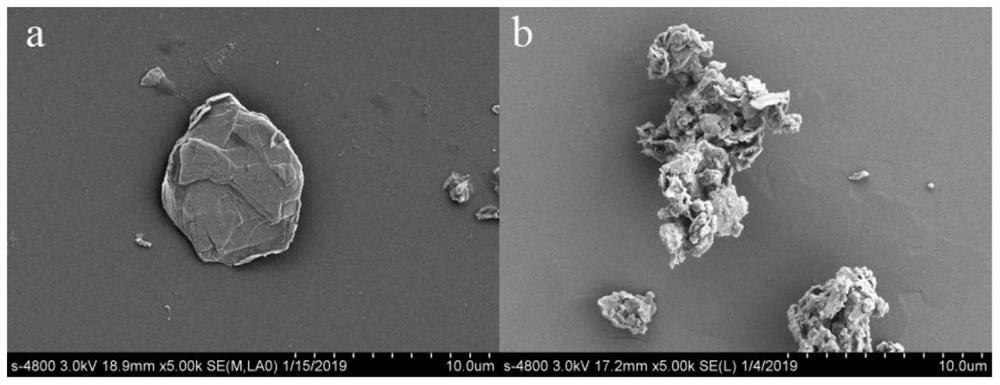

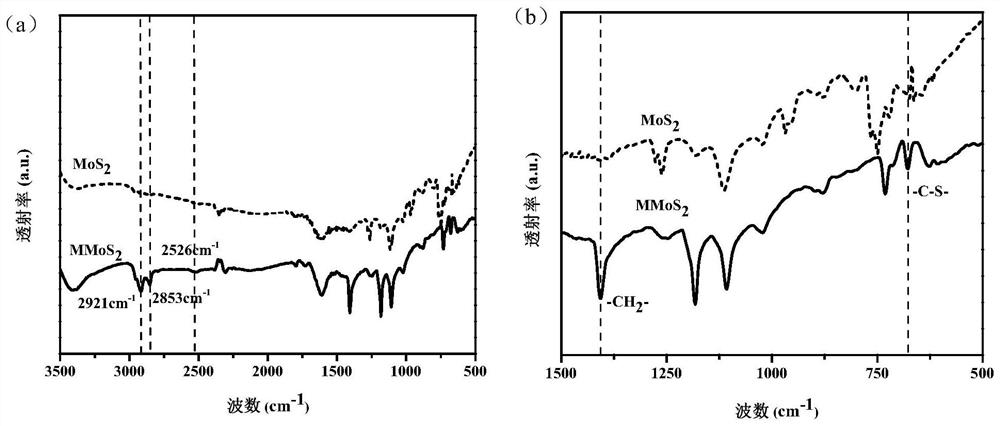

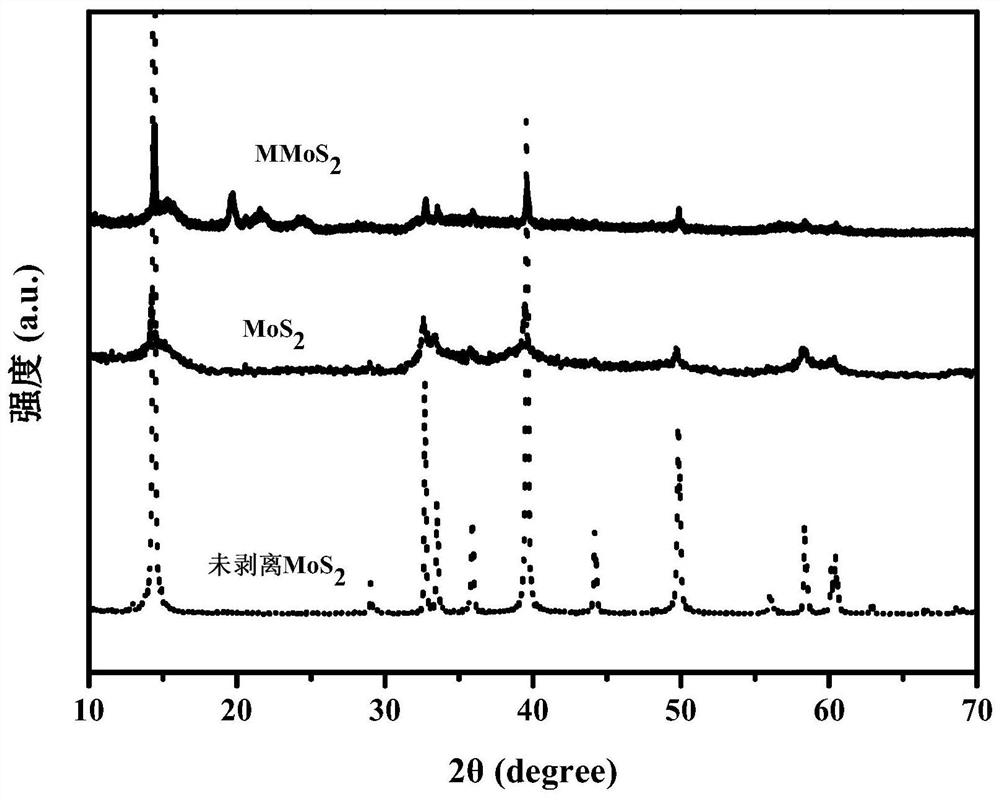

[0030] figure 1 Lamellar molybdenum disulfide (MoS 2 ) and ethanedithiol-modified nanomolybdenum disulfide (MMoS 2 ) scanning electron microscope (SEM). Molybdenum disulfide presents a very thin lamellar structure, indicating that the disulfide was successfully peeled off. The surface of nanomolybdenum disulf...

Embodiment 2

[0034] Example 2, Modification of lamellar molybdenum disulfide and ethanedithiol modified nano molybdenum disulfide to polysulfide sealant

[0035] The ethanedithiol modified nanomolybdenum disulfide used in this example is the sample in Example 1.

[0036] In this embodiment, the polysulfide sealant of the following components is taken as an example to verify the modification effect of the lamellar molybdenum disulfide and ethanedithiol-modified nano-molybdenum disulfide on it:

[0037] Polysulfide sealant is composed of base paste and vulcanization paste in a weight ratio of 10:1.

[0038] The composition of each component by weight in the base paste is:

[0039] Filler: 50 parts of nanometer calcium carbonate;

[0040] Plasticizer: 10 parts of butyl phthalate;

[0041] Silane coupling agent: 0.5 parts of bis-(2-(triethoxysilane) propyl)-tetrasulfide (silane coupling agent KH-69);

[0042] Liquid polysulfide rubber: 100 parts of LP-32 liquid polysulfide rubber (Toray Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com