Vaporization system and storage medium storing vaporization system program

一种气化系统、气化气体的技术,应用在气态化学镀覆、化学仪器和方法、化学/物理过程等方向,能够解决维护性变差、妨碍低成本化和紧凑化、价格高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

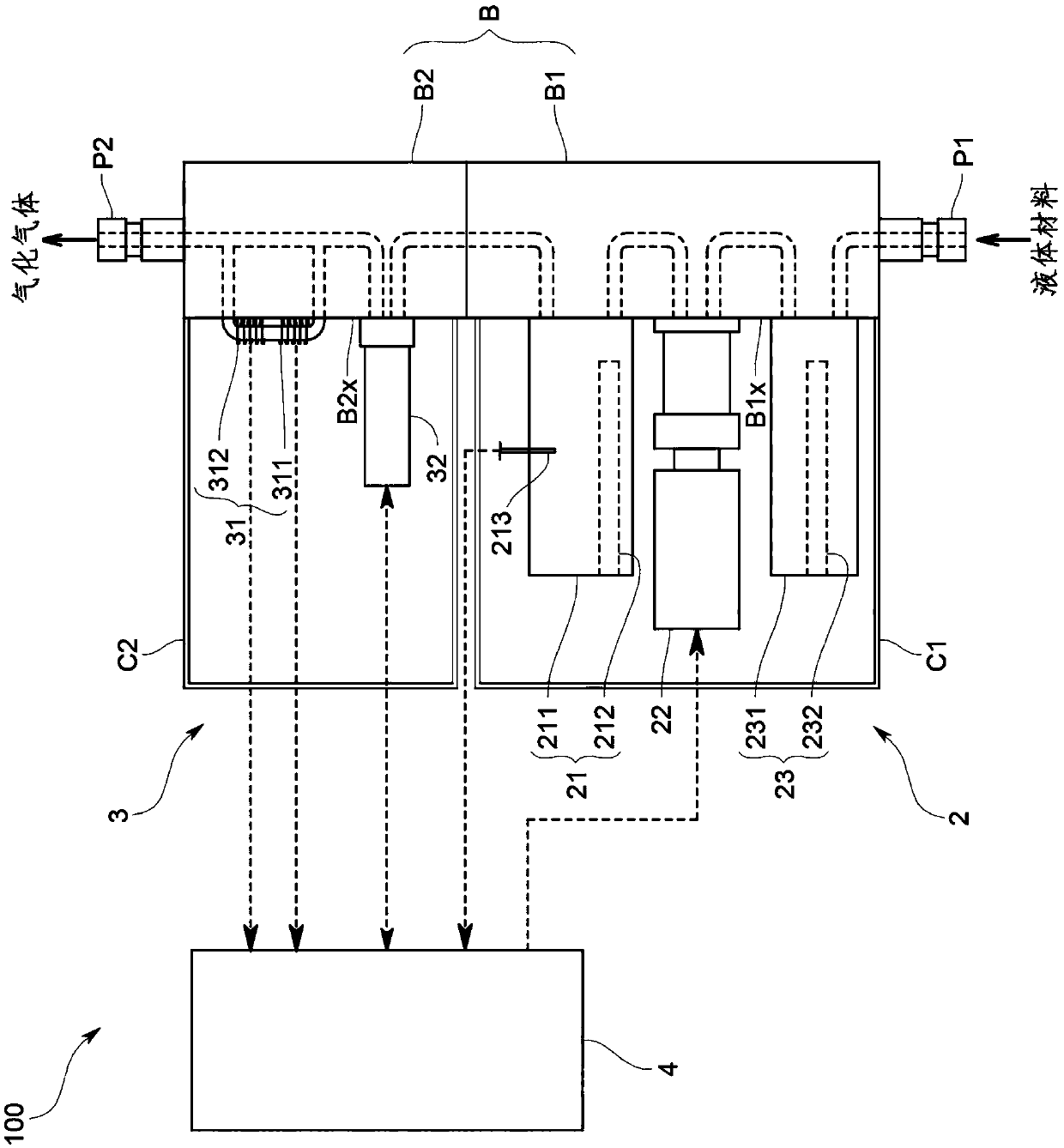

[0040] One embodiment of the gasification system of the present invention will be described below with reference to the drawings.

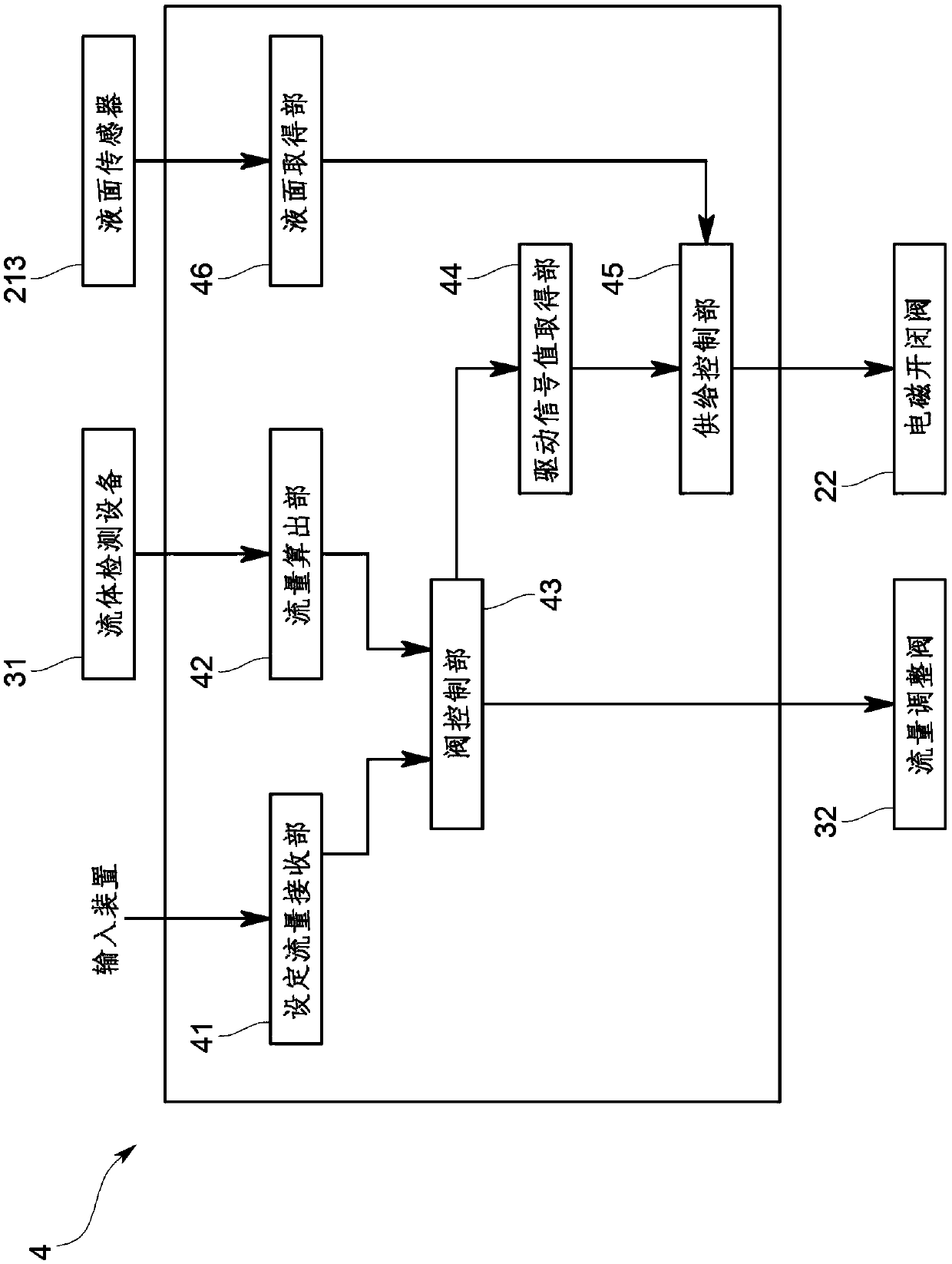

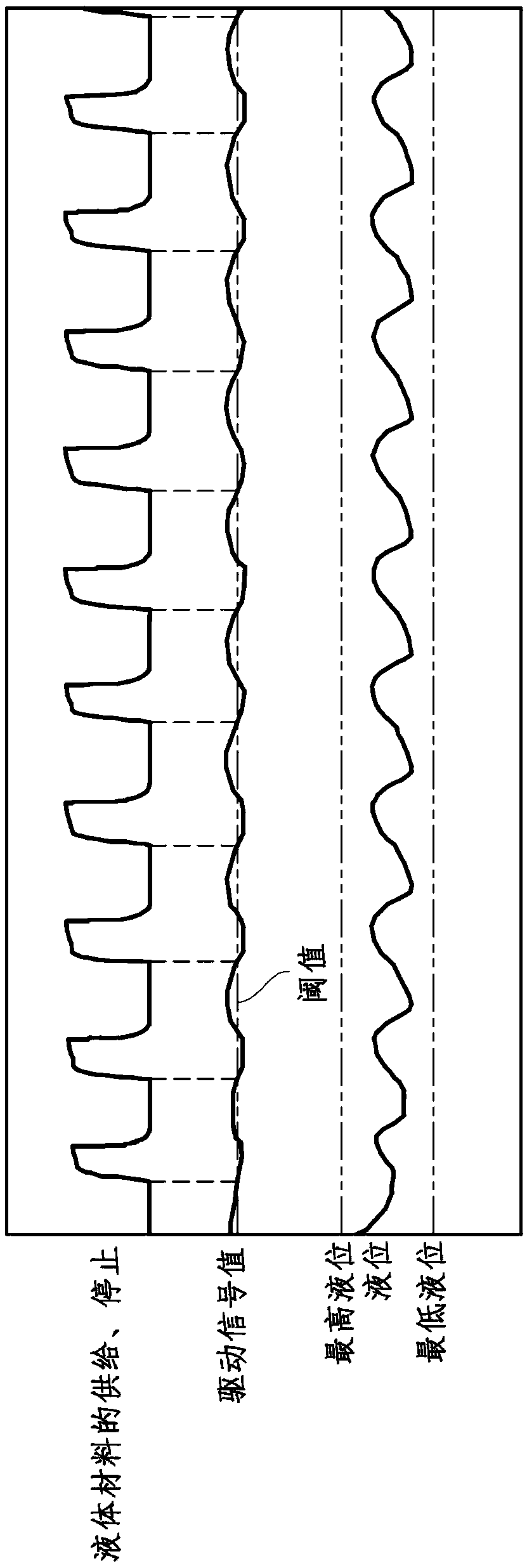

[0041] The gasification system 100 of this embodiment is installed in, for example, a semiconductor production line, etc., and is used to supply a predetermined flow rate of gas to a chamber in which a semiconductor manufacturing process is performed, such as figure 1 As shown, it includes: a gasification part 2, which vaporizes the liquid raw material; a mass flow controller 3, which controls the flow rate of the gas gasified by the gasification part 2; and a control device 4, which controls the gasification part 2 and mass flow control The action of device 3.

[0042] In addition, in this embodiment, each part constituting the vaporizer 2 is housed in the first case C1, and each part constituting the mass flow controller 3 is housed in the second case C2 different from the first case C1. Each part constituting the vaporization part 2 and each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com