Hydropower coproduction system capable of performing gradient utilization of flue gas waste heat concentrated solutions and working method of hydropower coproduction system

A concentrated solution and flue gas technology, applied in separation methods, chemical instruments and methods, steam engine devices, etc., can solve problems such as water shortage and difficult solution concentration, and achieve improved energy utilization, increased solution temperature, and equipment safety high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

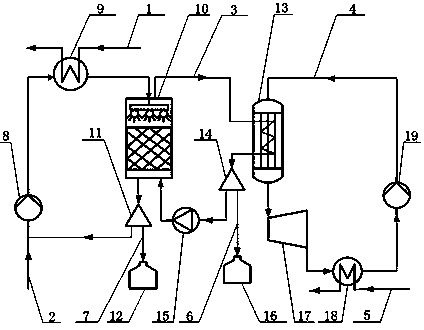

[0017] The following describes the working process of the cascade utilization of flue gas waste heat concentrated solution combined heat and power system with reference to the accompanying drawings.

[0018] First, start the solution pump 8, fan 15, and pump 19 in sequence;

[0019] The flue gas 1 enters the heater 9, and after heating the dilute solution 2, it is discharged from the heater 9.

[0020] The dilute solution 2 is transported to the heater 9 by the solution pump 8 for cold measurement, and after being heated by the flue gas 1 on the hot side, it enters the humidification tower 10, where it directly contacts with the low-temperature dry air 3 for heat and mass transfer, heating the air 3, and the water is taken away, the dilute solution 2 is concentrated and divided into two parts through the flow divider 11, one part enters the concentrated solution tank 12, and the other part re-enters the heater 9 to enter the next cycle.

[0021] The low-temperature dry air 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com