A method and device for evaporating and concentrating high-salt wastewater

A high-salt wastewater, evaporation and concentration technology, applied in chemical instruments and methods, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve damage to heat exchange equipment, increase cooling water consumption, consume large energy, etc. problems, to achieve the effect of saving equipment installation space, reducing water vapor loss, and improving safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

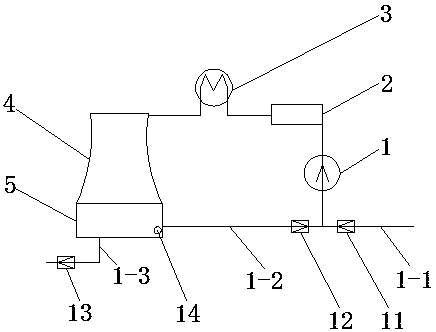

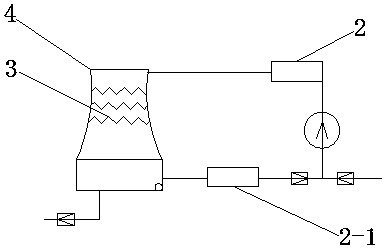

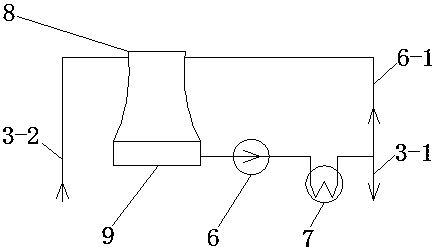

[0025] A method for evaporating and concentrating high-salt wastewater, including the process of heating, evaporating and concentrating high-salt wastewater, especially for wastewater discharged from a desulfurization device, because the water in the slurry of the desulfurization device will be enriched in heavy metal elements during the continuous circulation process On the one hand, it accelerates the corrosion of desulfurization equipment, and on the other hand, it affects the quality of gypsum. Therefore, a certain amount of wastewater must be discharged into the desulfurization wastewater treatment system. The wastewater entering the desulfurization wastewater treatment system has high content of suspended solids, organic matter, and some heavy metals. Ions need to undergo neutralization, flocculation and precipitation and other treatment processes; after reaching the standard, the high-salt wastewater evaporation and concentration method of the present invention is used fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com