Method for preparing carbon-loaded heteropoly acid material from wood fiber biomass

A technology for loading heteropolyacids and wood fibers, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as shedding, and achieve the effects of simple operation, broad application prospects, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing carbon-loaded molybdenum heteropolyacid material from lignocellulosic biomass, comprising the following steps:

[0032] (1) Weigh 0.2 mmol of sodium molybdate solid into a beaker filled with 20 mL of deionized water, and put it on a magnetic stirrer for stirring.

[0033] (2) Add 1g of wood crushed to the above solution, then add 0.5ml of phosphoric acid to the reaction system, transfer it into a stainless steel reaction kettle, and carry out hydrothermal synthesis reaction, the reaction temperature is 180°C, and the reaction time is 10h.

[0034] (3) After the reaction is finished, cool to room temperature, centrifuge and collect the product, and then ultrasonically wash it several times with deionized water and absolute ethanol.

[0035] (4) Carry out drying treatment in an oven to obtain a yellow-black carbon-supported molybdenum heteropolyacid material.

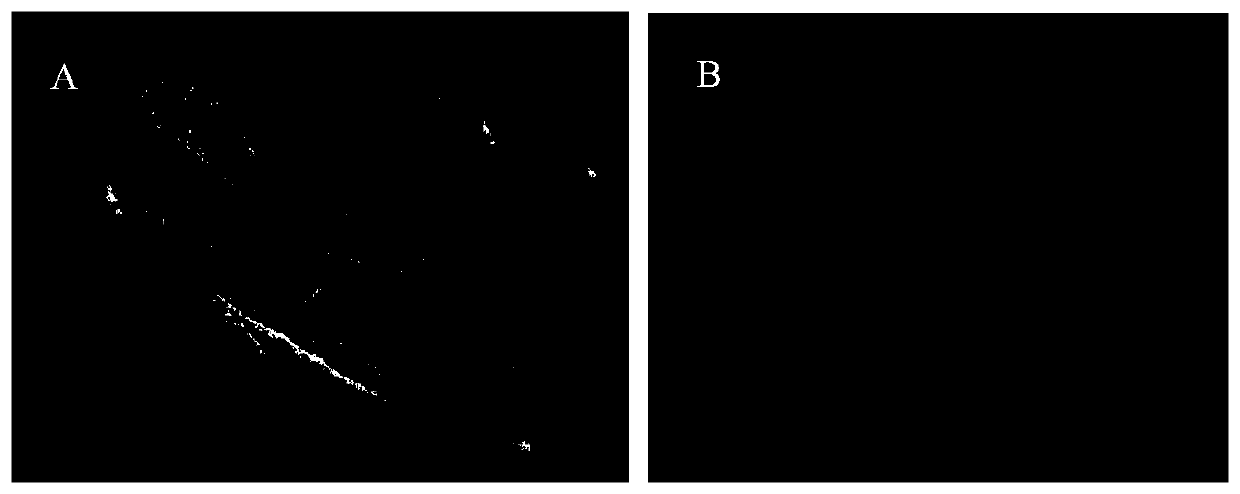

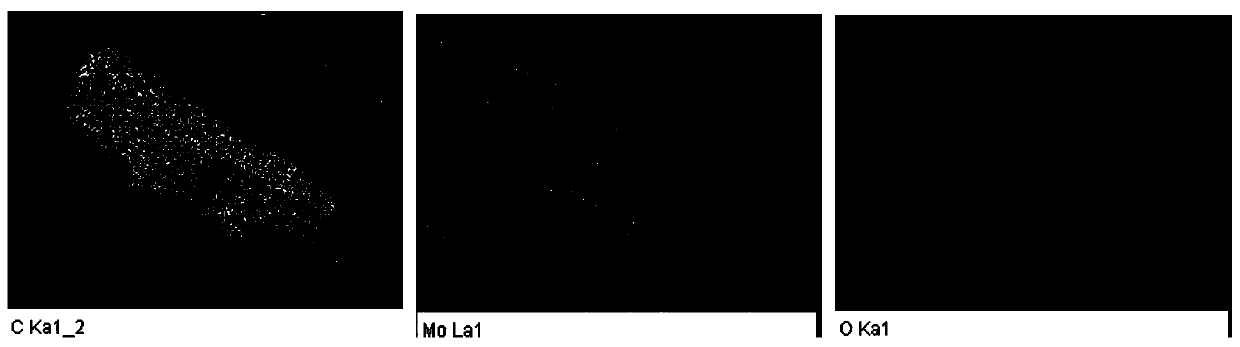

[0036] combine figure 1 It can be seen from A and B that when wood fiber is used as raw...

Embodiment 2

[0038] A method for preparing carbon-loaded tungstic heteropolyacid materials from lignocellulosic biomass, comprising the following steps:

[0039] (1) Weigh 0.2 mmol of sodium tungstate solid into a beaker filled with 20 mL of deionized water, and put it on a magnetic stirrer for stirring.

[0040] (2) Add 1g of wood crushed to the above solution, then add 0.5ml of phosphoric acid to the reaction system, transfer it into a stainless steel reaction kettle, and carry out hydrothermal synthesis reaction, the reaction temperature is 180°C, and the reaction time is 10h.

[0041] (3) After the reaction is finished, cool to room temperature, centrifuge and collect the product, and then ultrasonically wash it several times with deionized water and absolute ethanol.

[0042] (4) Drying in an oven can produce black carbon-supported tungstic acid polyacid materials.

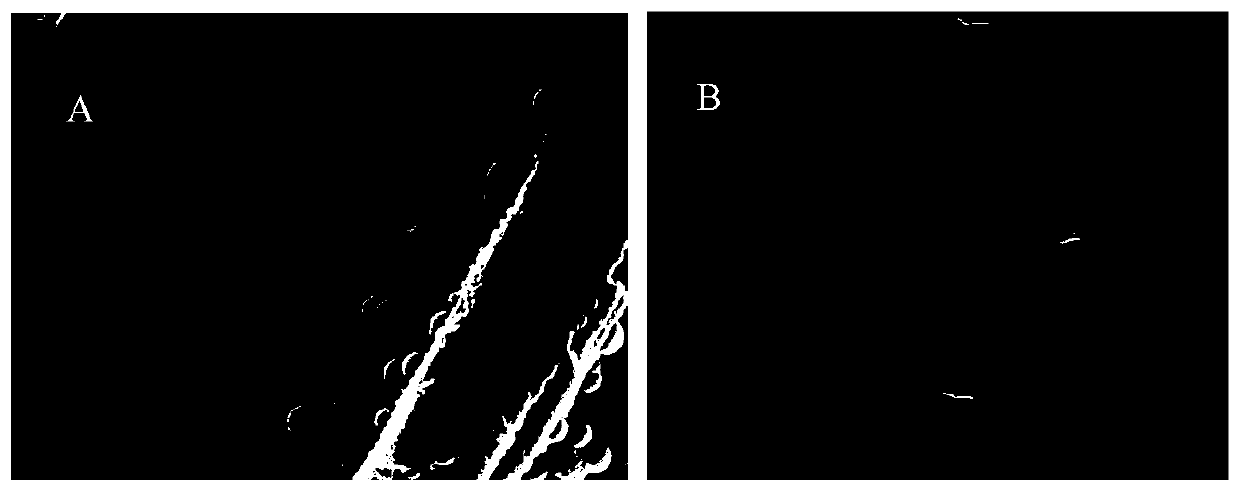

[0043] combine figure 2 It can be seen from A and B that when wood fiber is used as raw material, small particles ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com