Production method of polyphenylsulphone physical foaming sheet and production system thereof

A polyphenylene sulfone and physical foaming technology is applied in the field of polymer material processing to achieve the effects of fast heat conduction, high efficiency and excellent high temperature barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] A kind of production method step of polyphenylene sulfone physical foam sheet is as follows:

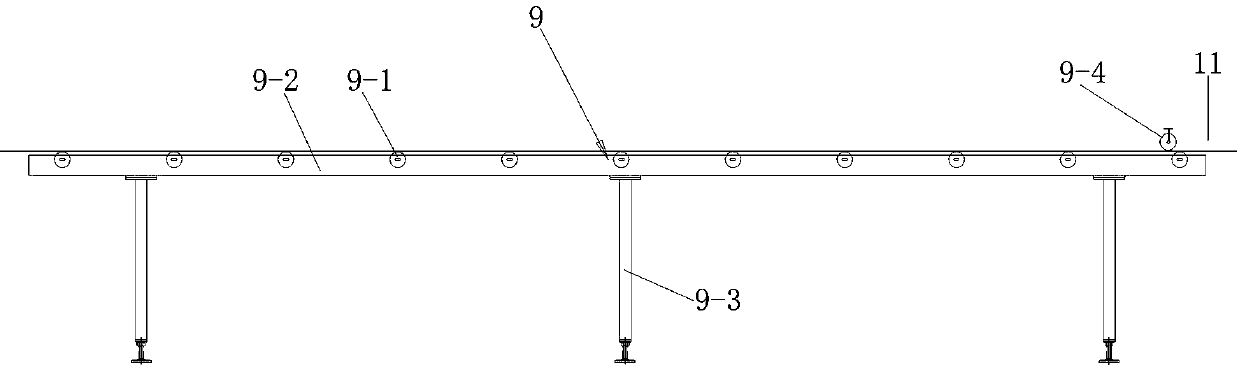

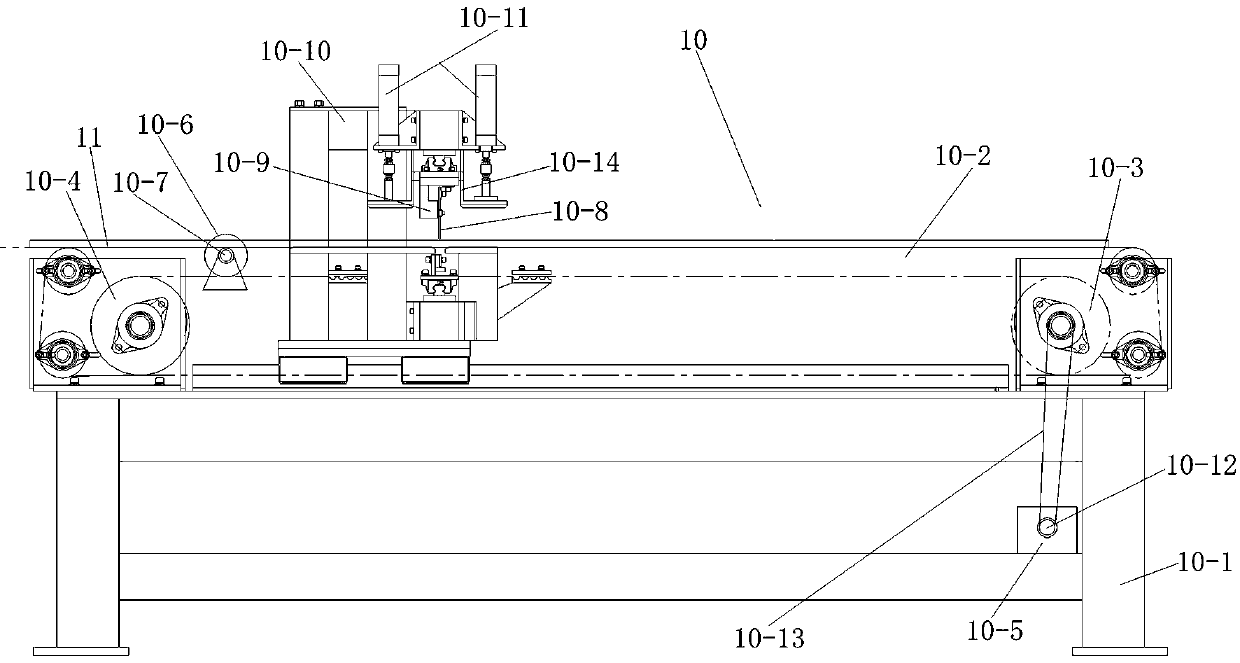

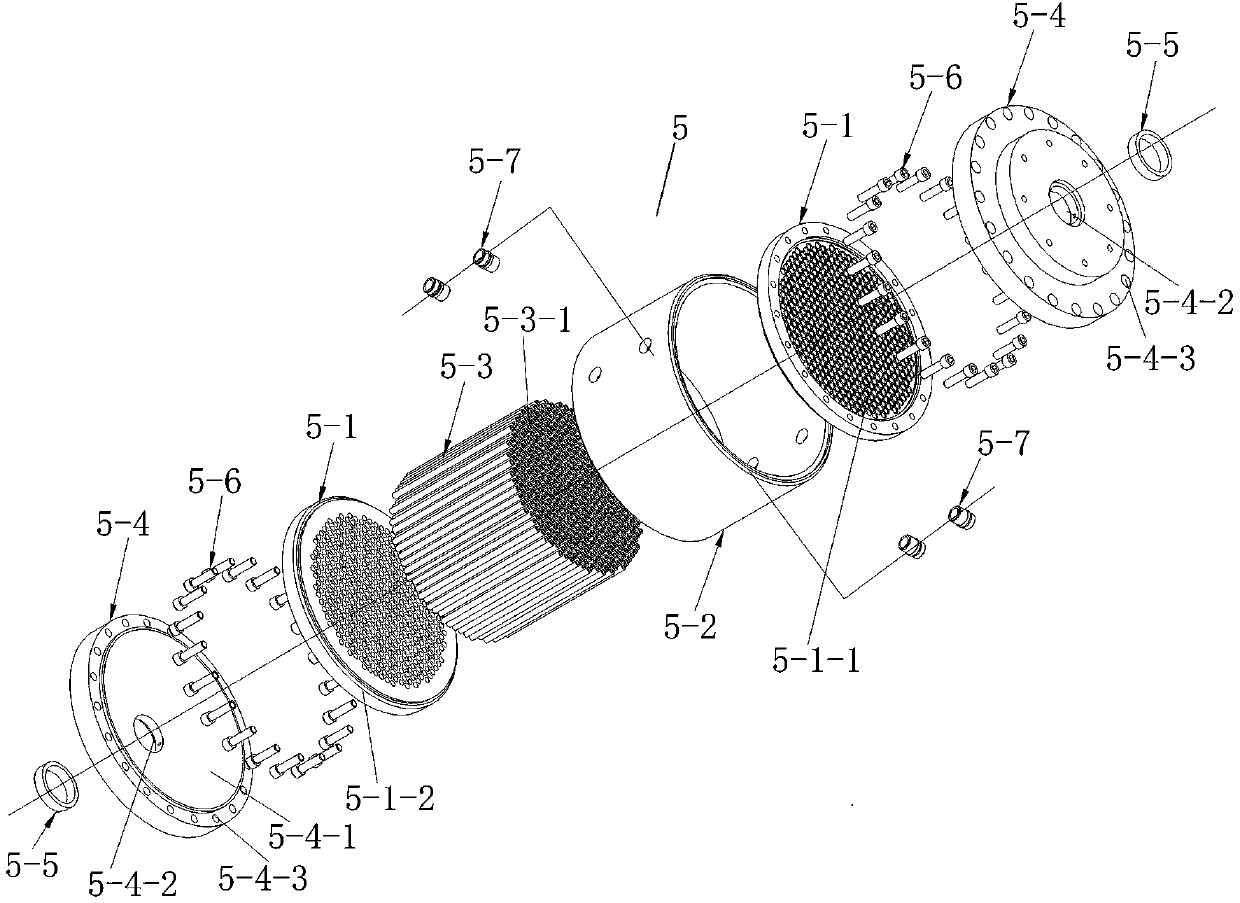

[0121] 1. Add 88kg of polyphenylene sulfone (PPSU) resin and 0.1kg of nucleating agent according to the weight ratio, and add them to the twin-screw extruder 2 through the feeder (feeding system) 1 for shearing and mixing, In the fourth section of the barrel of the twin-screw extruder 2, the metering pump of the foaming agent injection device 3 is used to inject 0.1 kg of liquid carbon dioxide foaming agent, carbon dioxide and PPSU resin nucleating agent, and are fully mixed through the twin-screw extruder to form Mixed melt, the temperature of the mixed melt is 250 degrees, the mixed melt (melt) is filtered by the screen changer 4 to filter the impurities in the mixed melt, and the heat exchanger 5 is used to reduce the temperature of the mixed melt, so that the mixed melt The temperature evenly drops to about 220 degrees, and is extruded through the extrusion die 6 extrusion...

Embodiment 2

[0126] A kind of production method step of polyphenylene sulfone physical foam sheet is as follows:

[0127] 1. Add 100kg of polyphenylene sulfone (PPSU) resin and 2kg of nucleating agent according to the weight ratio, and add them to the twin-screw extruder 2 through the feeder (feeding system) 1 for shearing and mixing. In the fourth section of the barrel of the twin-screw extruder 2, the metering pump of the blowing agent injection device 3 is used to inject 10 kg of liquid carbon dioxide foaming agent, carbon dioxide and PPSU resin nucleating agent, and are fully mixed through the twin-screw extruder to form a mixed melt. body, the temperature of the mixed melt is 260 degrees, the mixed melt (melt) is filtered by the screen changer 4 to filter the impurities in the mixed melt, and the heat exchanger 5 is used to reduce the temperature of the mixed melt, so that the temperature of the mixed melt is uniform Drop to about 220 degrees, and extrude through extrusion die head 6 ...

Embodiment 3

[0132] A kind of production method step of polyphenylene sulfone physical foam sheet is as follows:

[0133] 1. Add 95 kg of polyphenylene sulfone (PPSU) resin and 1 kg of nucleating agent according to the proportion by weight, and add them to the twin-screw extruder 2 through the feeder (feeding system) 1 for shearing and mixing. In the fourth section of the barrel of the twin-screw extruder 2, the metering pump of the foaming agent injection device 3 is used to inject 5 kg of liquid carbon dioxide foaming agent, carbon dioxide and PPSU resin nucleating agent, and are fully mixed through the twin-screw extruder to form a mixed melt. body, the temperature of the mixed melt is 255 degrees, the mixed melt (melt) is filtered by the screen changer 4 to filter the impurities in the mixed melt, and the heat exchanger 5 is used to reduce the temperature of the mixed melt, so that the temperature of the mixed melt is uniform Drop to about 220 degrees, and extrude through extrusion die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com