Treatment method of basic etching waste liquid

A technology for etching waste liquid and treatment methods, applied in separation methods, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of high cost, waste of heating energy, waste of precious resources, etc., to prevent germs from invading Infection, preventing spore germination, and improving disease resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The water quality of an alkaline etching waste liquid is: nitrogen ammonia concentration 40000 mg / L, copper ion concentration 50000 mg / L, pH value 8.3, and a total volume of 100L. The specific process is as follows:

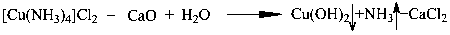

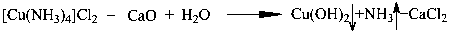

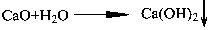

[0023] 1) Add excessive CaO solids to the raw material waste until the pH value is 12.0, so that the ammonium ions in the wastewater are converted into ammonia molecules, including ammonia gas and ammonia molecules dissolved in the waste liquid. In order to fully precipitate, the waste liquid is introduced into the ammonia distillation tower to Ammonia evaporates, and there are excess hydroxide ions, generating Cu(OH) 2 Precipitation, excess CaO converted to white precipitate Ca(OH) 2 , with Cu(OH) 2 Blending into a blue-white precipitate, and the remaining waste liquid contains calcium chloride;

[0024] 2) The overflowing ammonia gas is absorbed by the absorption tower and converted into a 30% ammonia solution. The ammonia gas absorption tower mainly u...

Embodiment 2

[0029] The water quality of an alkaline etching waste liquid is: nitrogen ammonia concentration 50000 mg / L, copper ion concentration 60000 mg / L, pH value 8.0, and a total volume of 200L. The specific process is as follows:

[0030] 1) Add excessive CaO solids to the raw material waste until the pH value is 12.0, so that the ammonium ions in the wastewater are converted into ammonia molecules, including ammonia gas and ammonia molecules dissolved in the waste liquid. In order to fully precipitate, the waste liquid is introduced into the ammonia distillation tower to Ammonia evaporates, and there are excess hydroxide ions, generating Cu(OH) 2 Precipitation, excess CaO converted to white precipitate Ca(OH) 2 , with Cu(OH) 2 Blending into a blue-white precipitate, and the remaining waste liquid contains calcium chloride;

[0031] 2) The overflowing ammonia gas is absorbed by the absorption tower and converted into a 30% ammonia solution. The ammonia gas absorption tower mainly u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com