Industrial lubricating oil purification and repair process integration device

A waste lubricating oil, industrial technology, applied in the direction of lubricating compositions, etc., can solve the problems of economic loss, loss of functional additives, removal, etc., to achieve the effect of convenient use and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

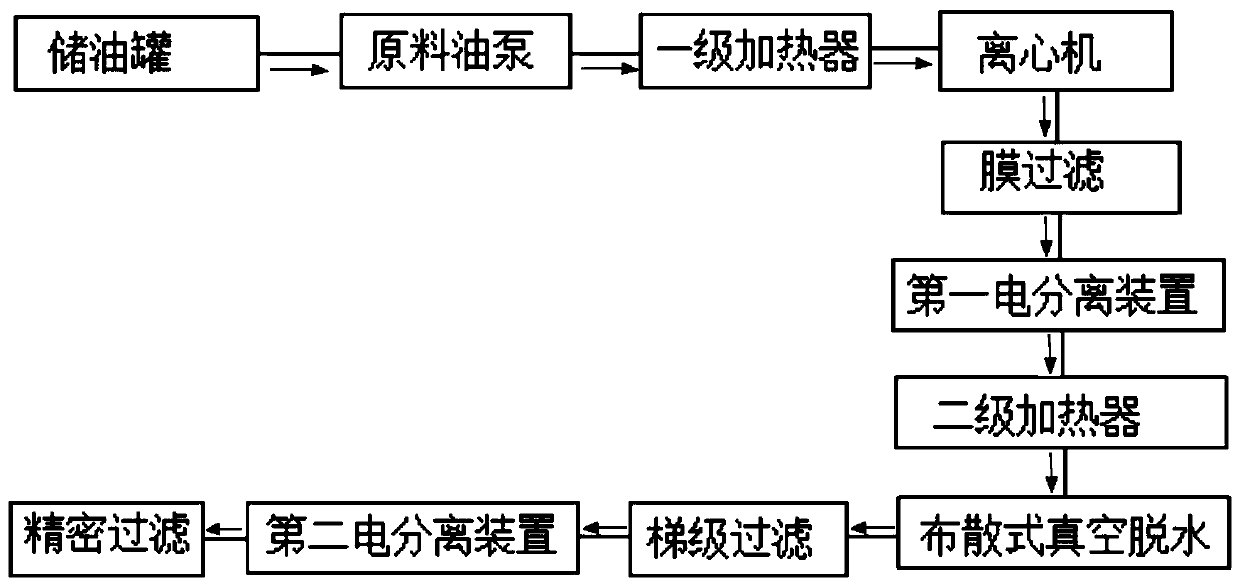

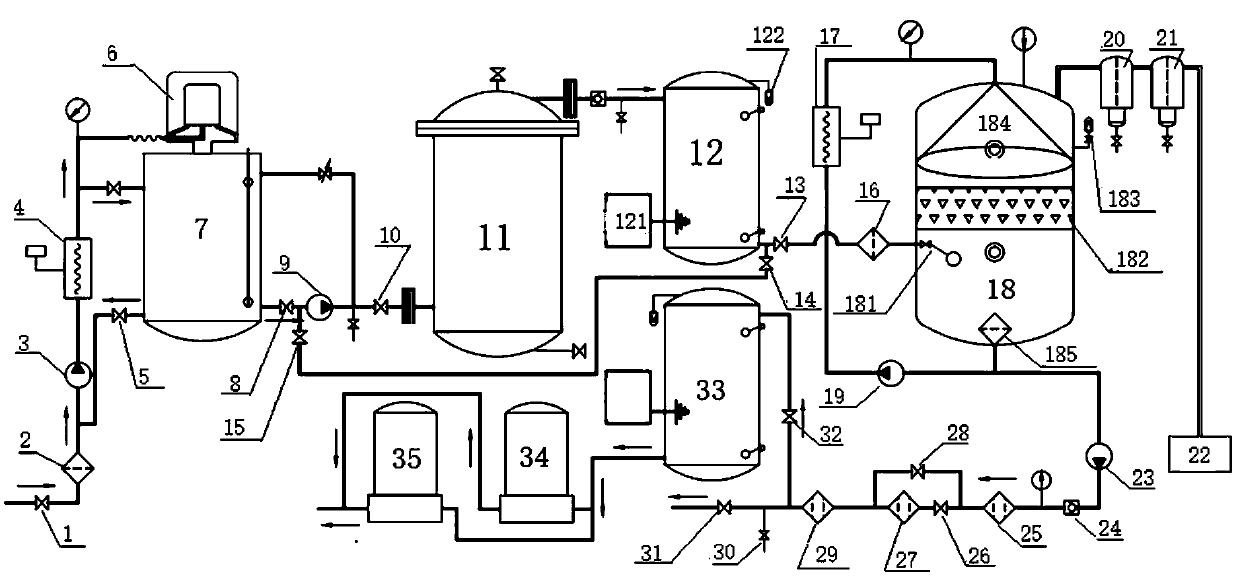

Method used

Image

Examples

Embodiment 1

[0029] For example: No. 46 turbine oil in use: cleanliness greater than grade 12 (NAS-1638), moisture content 310mg / kg, acidity 0.08mgKOH / g, iron: greater than 6 mg / Kg. Including the following steps:

[0030] 1. Preheating: heat the raw materials to 58°C.

[0031] 2. High-speed centrifugal separation: The centrifuge speed is greater than 4500r / min, the separation factor Fr is greater than 3500, the centrifugal acceleration is greater than 3000g, and the particles with a particle size greater than 30μm are removed.

[0032] 3. Polymer organic membrane filtration: Polymer organic membrane coalescence dehydration filter is used to remove particle pollutants and part of the water with a particle size above 15 μm.

[0033] 4. First-level electroseparation: first-level electrosorption separation (voltage 1100V, current 12mA), focusing on the removal of metal debris particles.

[0034] 5. Distributed vacuum dehydration: reheat to 63°C in the second stage, enter the distributed vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| eccentricity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com