Multi-mode switching power transmission system with variable planetary gear characteristic parameters

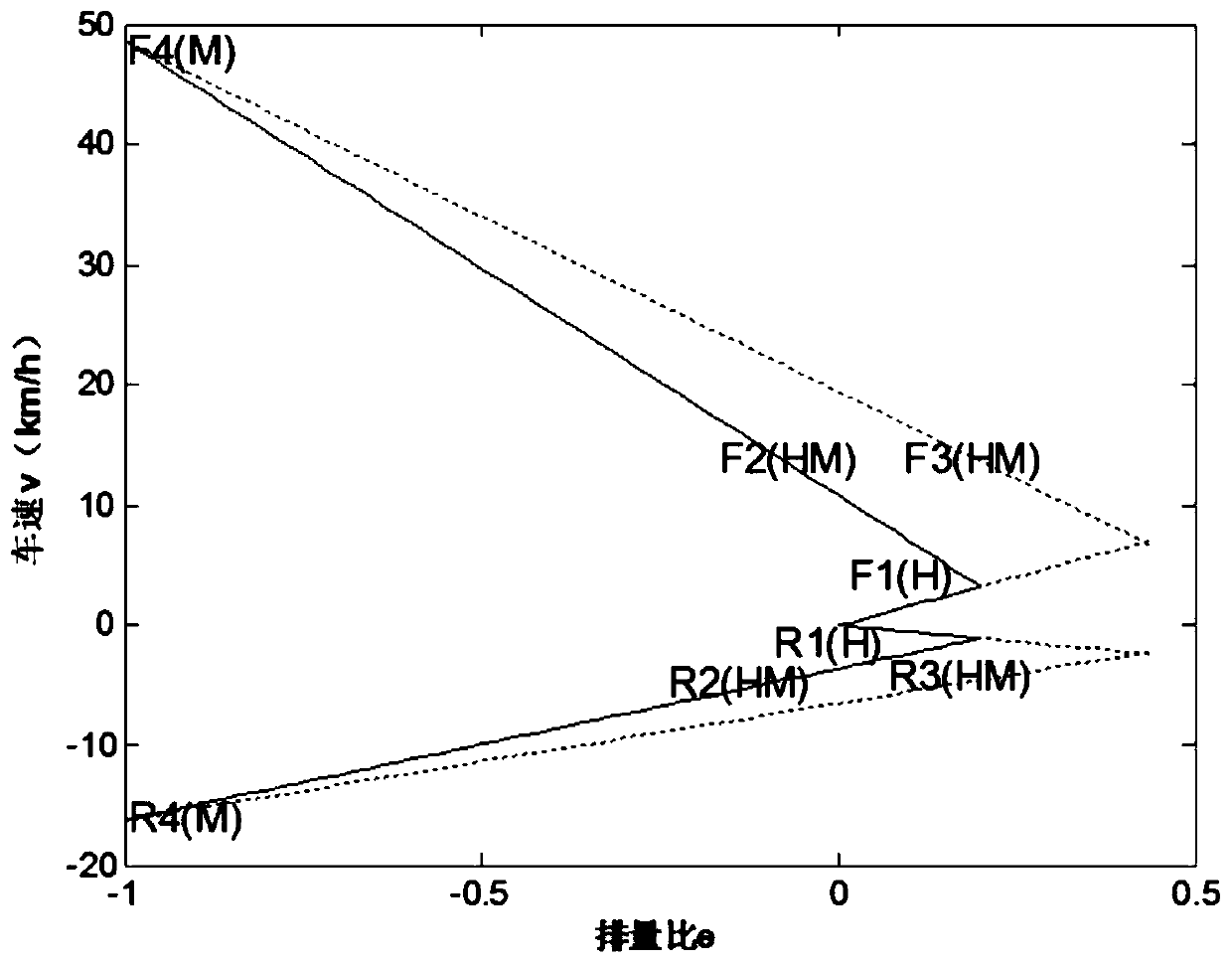

A power transmission system and planetary gear technology, applied in the field of transmission system, can solve the problems of transmission system power interruption, torque limited by oil pressure and displacement, low flexibility, etc., to achieve automatic adaptation to changes in driving resistance, expansion speed Higher effect than range, operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

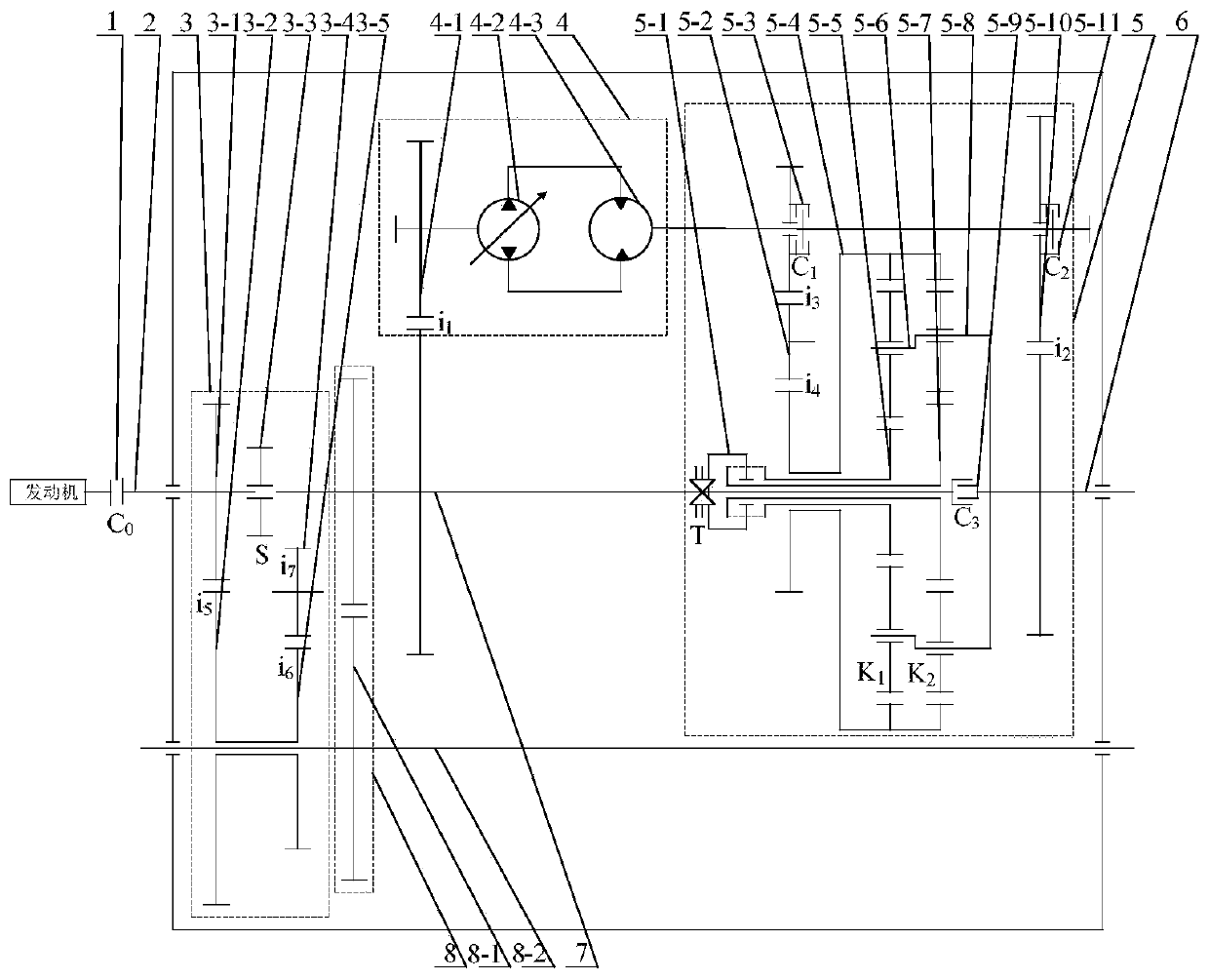

[0029] Example 1, such as figure 1 As shown, the multi-mode switching power transmission system with variable planetary gear characteristic parameters in the present invention includes a main clutch 1, an input shaft 2, a forward and reverse gear assembly 3, an intermediate shaft 7, a hydraulic transmission assembly 4, and a planetary gear Assembly 5, output shaft 6 and power output assembly 8; the main clutch 1 is used to connect the power source and the input shaft 2.

[0030] The forward and reverse gear assembly 3 includes a reverse gear speed-up driving gear 3-1, a reverse gear speed-up driven gear 3-2, a shift gear 3-3 with a spline sleeve, a reverse gear idler gear 3-4 and The reverse speed reduction driving gear 3-5; the reverse speed speed up driving gear 3-1 meshes with the reverse speed speed up driven gear 3-2, and the reverse speed speed up driving gear 3-1 is connected with the input shaft 2; The reverse gear idler gear 3-4 meshes with the reverse gear decelerat...

Embodiment 2

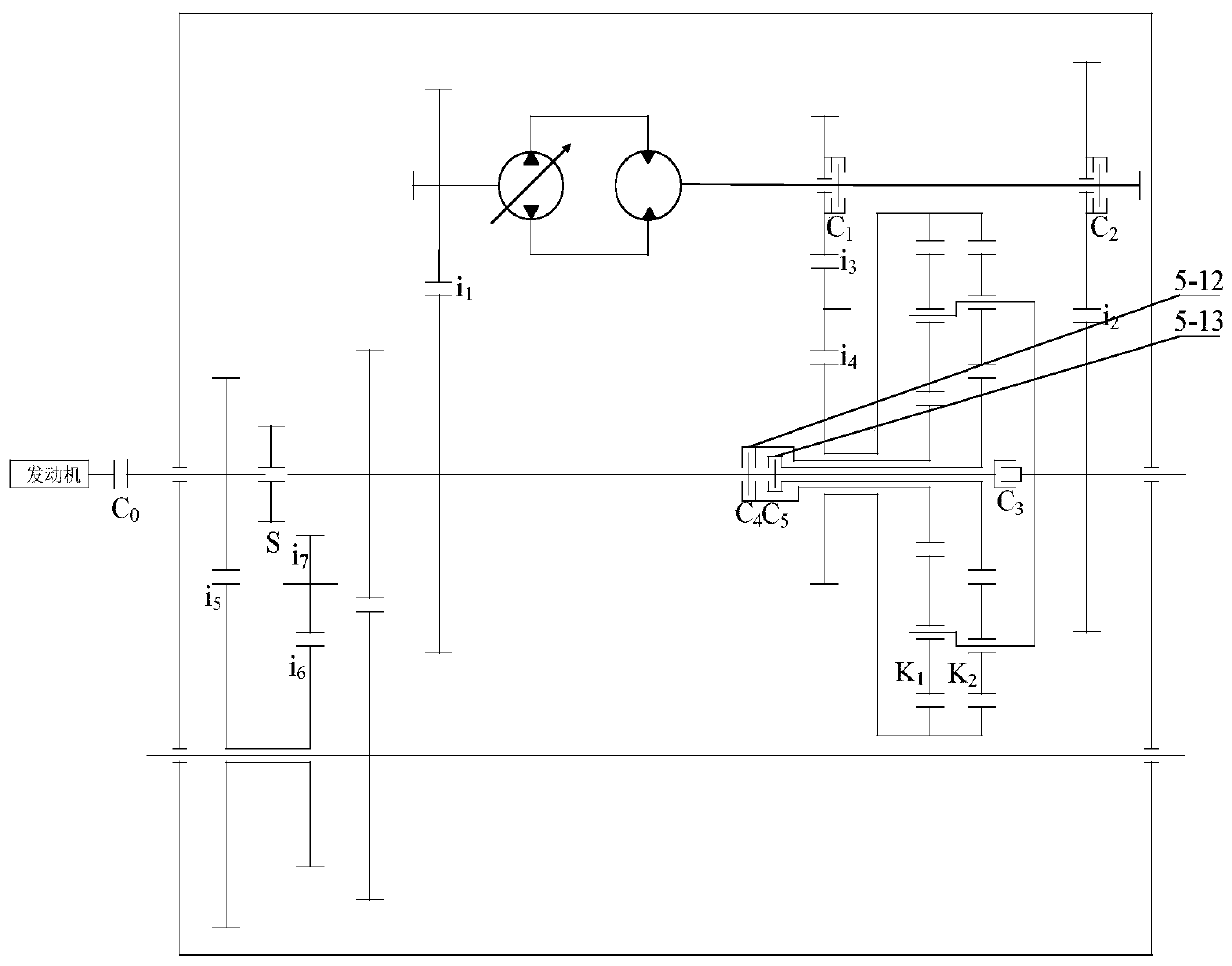

[0048] Example 2, such as image 3 As shown, the planetary gear sleeve 5-1 can be replaced by the fourth clutch 5-12 and the fifth clutch 5-13, and the fifth clutch 5-13 is used to selectively connect the rear planetary gear train The sun gear is connected with the input member; the fourth clutch 5-12 is used to selectively connect the sun gear of the front planetary gear train with the input member for common rotation. Only need to simultaneously switch the fourth clutch 5-12 and the fifth clutch 5-13 can achieve the purpose of switching the planetary gear sleeve 5-1 in Embodiment 1, and it is more precise.

Embodiment 3

[0049] Example 3, such as Figure 4 As shown, the planetary gear assembly 5 is a single planetary gear train, and the clutch assembly includes a sixth clutch 5-14, a seventh clutch 5-15, an eighth clutch 5-16 and a ninth clutch 5-17; The sixth clutch 5-14 is used to selectively connect the front planet carrier of the single planetary gear train with the intermediate shaft 7; the seventh clutch 5-15 is used to selectively connect the front planet carrier of the single planetary gear train The sun gear of the single planetary gear system is connected to the intermediate shaft 7; the eighth clutch 5-16 is used to selectively connect the sun gear of the single planetary gear system to the output shaft 6; the ninth clutch 5-17 is used to selectively Connect the rear planet carrier of the single planetary gear train with the output shaft 6; engage the first clutch 5-3, the sixth clutch 5-14 and the eighth clutch 5-16 to provide the input shaft 2 and the output shaft 6 Between hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com