Temperature-controlled coaxial refrigeration cable

A cable and coaxial technology, used in the field of temperature-controlled coaxial refrigeration cables and cable manufacturing, can solve the problems of inability to accurately adjust the working temperature and current carrying capacity of the cable, unfavorable long-term stable operation of the cable, and increase in the outer diameter of the finished cable. Accurate and controllable working temperature, saving installation space, and obvious cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

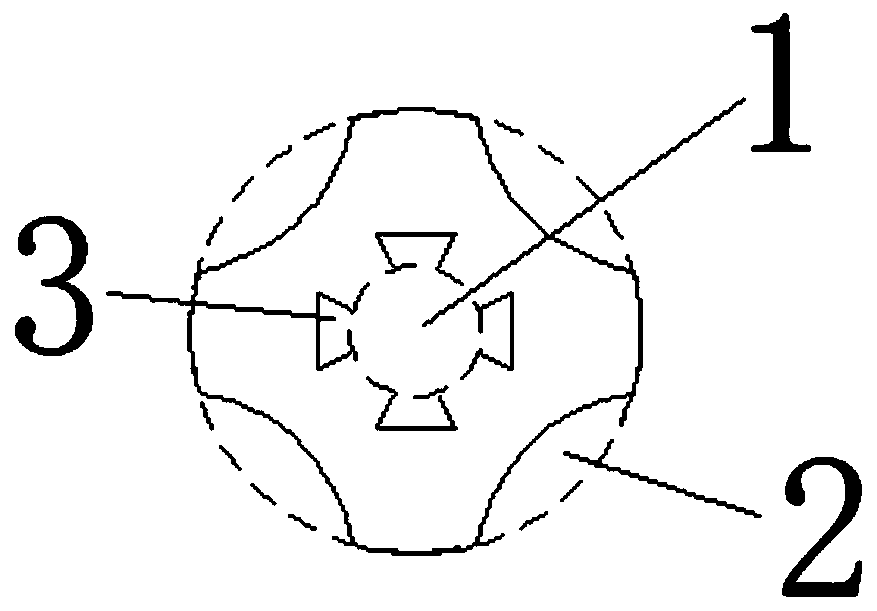

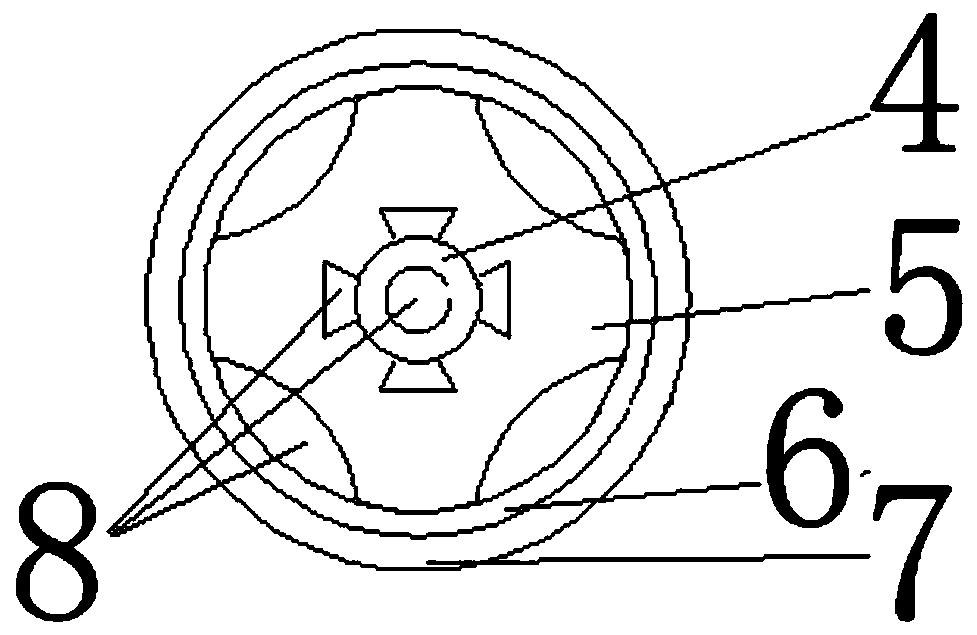

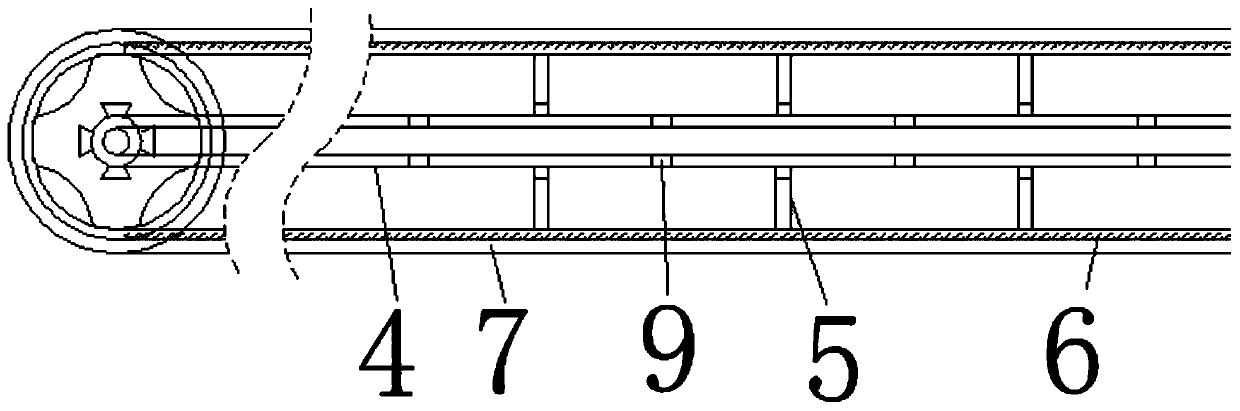

[0029] Temperature-controlled coaxial refrigeration cables, such as figure 1 , 2 Shown in , 3, comprise cable core, described cable core comprises inner conductor 4, outer conductor 6, has outer sheath 7 outside outer conductor, specifically:

[0030] Inner conductor 4: The inner conductor 4 is made of seamless copper pipe, and the cross-sectional area of the copper pipe can be properly adjusted according to the current carrying capacity. Since the inner conductor 4 adopts a tubular structure and the surface of the conductor has periodic and evenly distributed slots, it allows cooling The coolant circulates quickly inside and outside the inner conductor 4, and the working temperature of the cable can be adjusted by controlling the circulation speed of the coolant as required.

[0031] Outer conductor 6: The outer conductor 6 is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com