Tellurium sulfide polyacrylonitrile cathode material and preparation method thereof

A technology of tellurium sulfide polyacrylonitrile and positive electrode materials, which is applied in battery electrodes, electrical components, circuits, etc., can solve the problems of low discharge potential and poor rate performance, and achieve improved conductivity, reduced polarization, and high discharge potential Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Weigh 2 g of tellurium powder and 100 g of sublimed sulfur, grind them evenly, heat them in a tube furnace to 450° C. and keep them warm for 10 hours to obtain tellurium sulfide. Weigh 24g of tellurium sulfide, 3g of nickel sulfide and 6g of polyacrylonitrile, grind them evenly, heat them in a tube furnace at 350°C and keep them warm for 5 hours to obtain tellurium sulfide polyacrylonitrile, the material has a tellurium content of 2.1%, and a sulfur content of was 47.5%. Under the current density of 100mA / g, the average discharge voltage is 1.92V, the stable cycle capacity of the material reaches 660mAh / g, and the average coulombic efficiency is more than 99%.

example 2

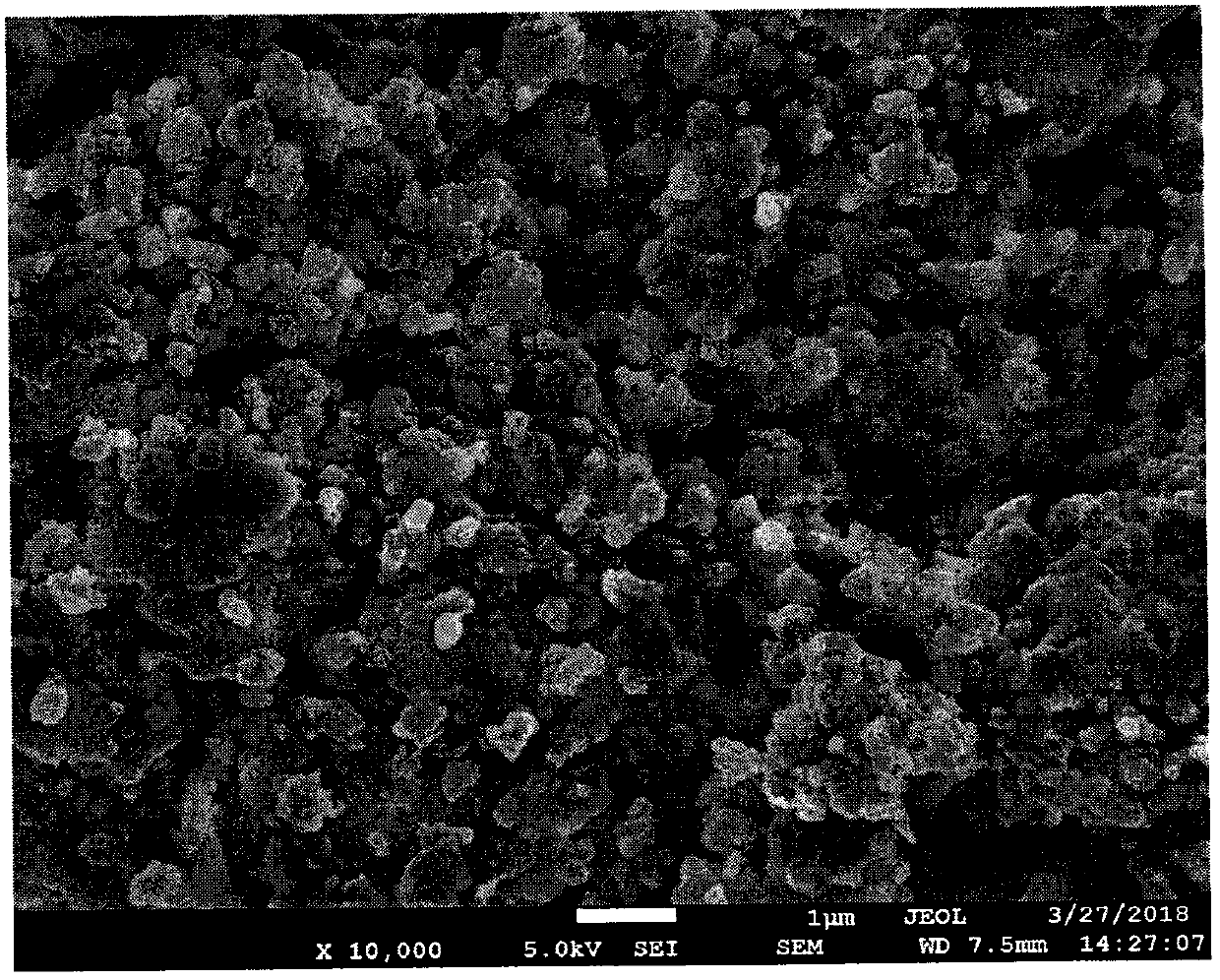

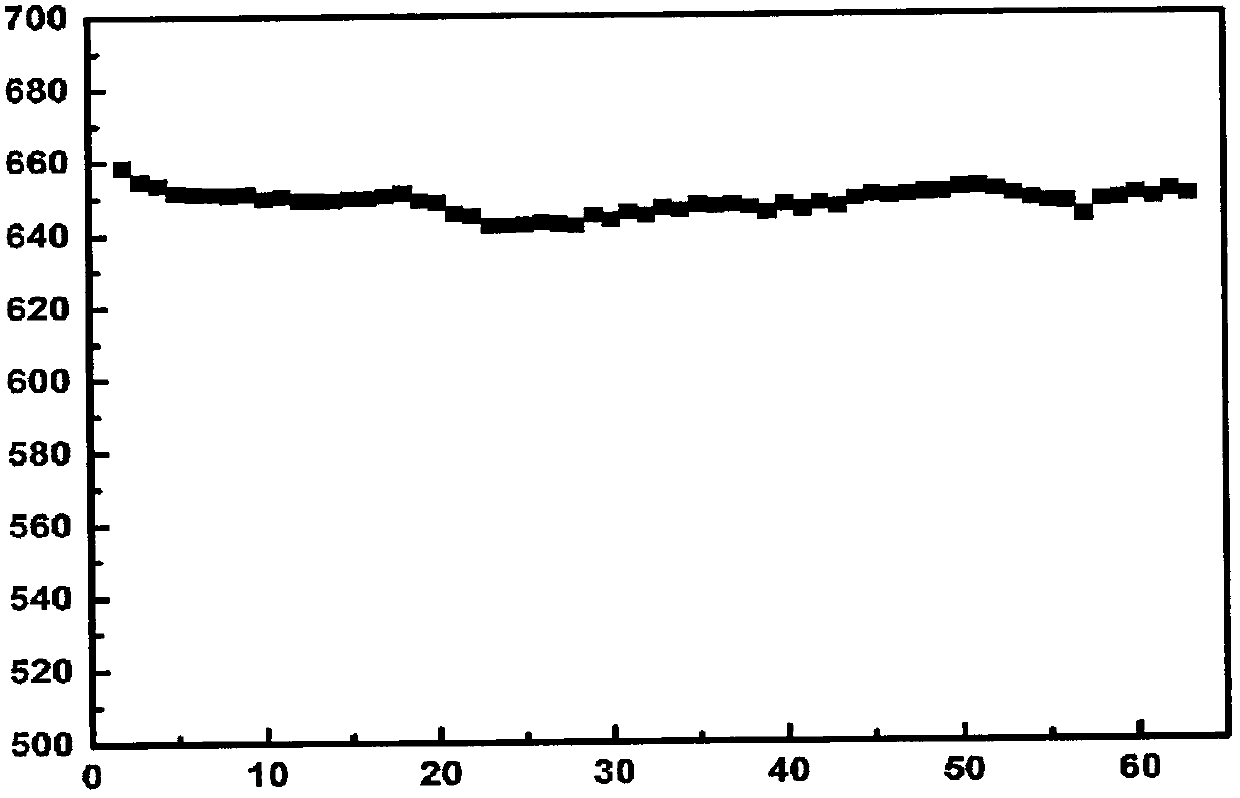

[0024] Weigh 12 g of tellurium powder and 100 g of sublimed sulfur, grind them evenly, heat them in a tube furnace to 450° C. and keep them warm for 10 hours to obtain tellurium sulfide. Weigh 24g of tellurium sulfide, 4g of lanthanum oxide and 6g of polyacrylonitrile, grind them evenly, heat them in a tube furnace at 350°C and keep them warm for 5 hours to prepare tellurium sulfide polyacrylonitrile, see attached figure 1 , the material tellurium content is 3.2%, and the sulfur content is 46.8%. Under the current density of 100mA / g, the average discharge voltage is 1.93V, the stable cycle capacity of the material reaches 650mAh / g, and the average Coulombic efficiency is >99%, see attached figure 2 .

example 3

[0026] Weigh 12 g of tellurium powder and 100 g of sublimed sulfur, grind them evenly, heat them in a tube furnace to 450° C. and keep them warm for 10 hours to obtain tellurium sulfide. Add 10 g of acrylonitrile into 500 g of DMF, stir to dissolve, add 0.02 g of azobisisobutyronitrile, and react for 3 hours under the protection of nitrogen to obtain polyacrylonitrile. Add 24g of tellurium sulfide and 3g of nickel sulfide to the reaction solution, stir evenly, filter, remove DMF, and dry to obtain a mixture containing tellurium sulfide, nickel sulfide and polyacrylonitrile. The above mixture was heated to 300° C. in a tube furnace and kept for 5 hours to obtain a tellurium sulfide polyacrylonitrile positive electrode material. The material has a tellurium content of 3.3% and a sulfur content of 48.3%. At a current density of 100mA / g, the stable cycle capacity of the material reaches 680mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com