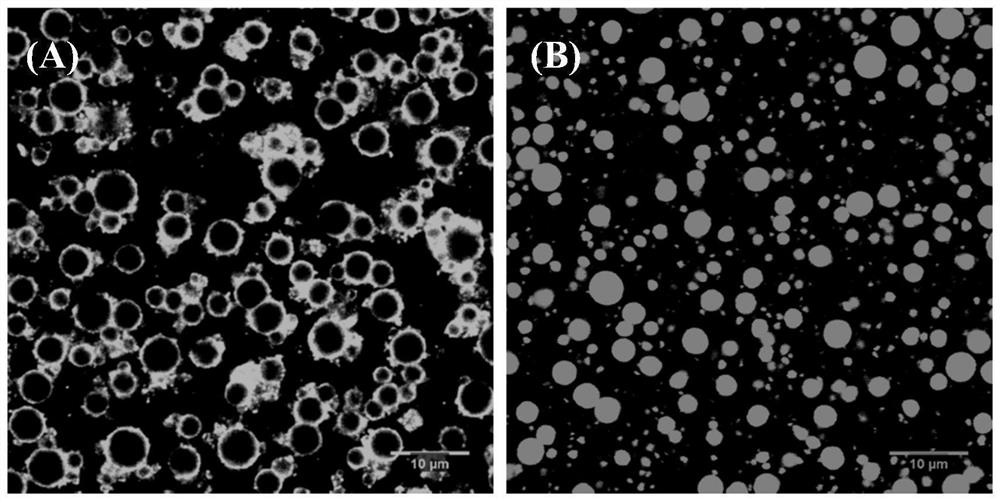

Liposome-stabilized oil-in-water pickering emulsion and preparation method thereof

A liposome, oil-in-water technology, applied in liposome delivery, emulsion delivery, preparations for skin care, etc., can solve the problem of inability to maximize the use of resources, single embedded material, uneven particle size distribution, etc. problems, to achieve good practical use value, improve stability, and improve the effect of taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

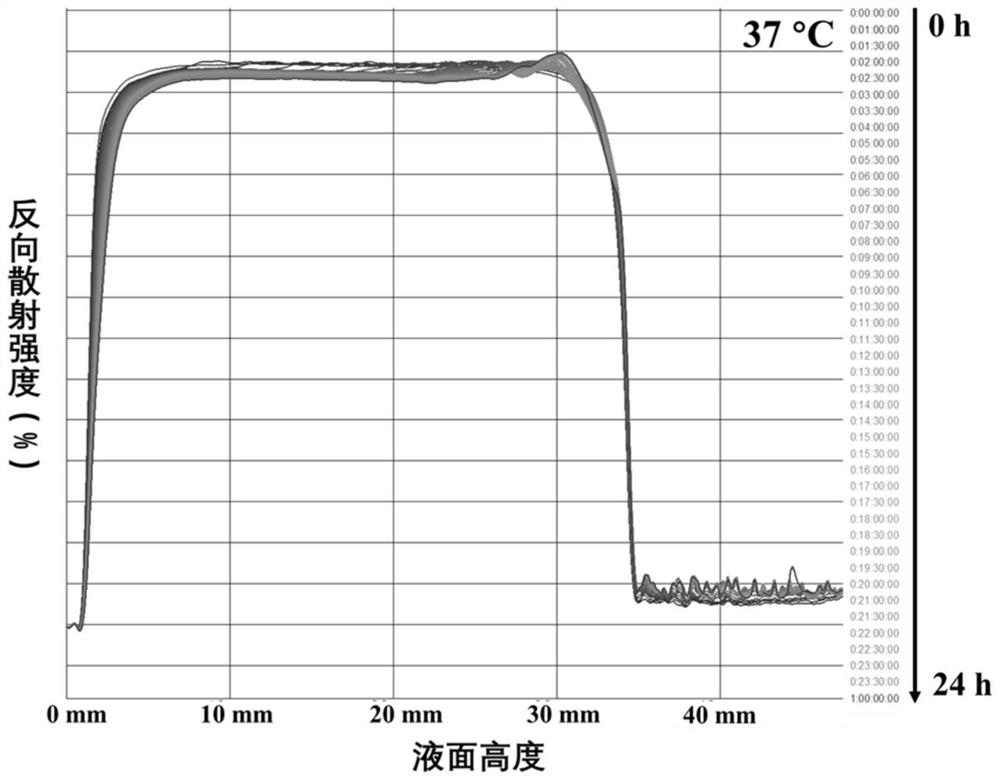

Method used

Image

Examples

preparation example Construction

[0046] Such as figure 1 Shown, be the preparation method flowchart of the oil-in-water Pickering emulsion that liposome is stable of the present invention, mainly comprise the following steps:

[0047] (1) Preparation of polyethylene glycol aqueous solution: mix a certain quality of polyethylene glycol with ultrapure water, stir until fully dissolved, and remove insoluble matter by centrifugal force of 5000g;

[0048] (2) Preparation of sunflower oil solution: dissolve DPPC in ethanol, remove ethanol by rotary evaporation and form a lipid film in the rotary steamer, add sunflower oil, and slowly stir until DPPC is completely dissolved;

[0049] (3) Preparation of emulsion: take the polyethylene glycol aqueous solution in step (1) and the sunflower oil solution in (2), mix evenly, then shear with a high-speed shear, and homogenize twice with a high-pressure homogenizer form an emulsion;

[0050] (4) Preparation of freeze-dried powder: After freezing the emulsion obtained in s...

Embodiment 1

[0056] (1) Preparation of polyethylene glycol aqueous solution: mix 10 g of polyethylene glycol with 90 mL of ultrapure water, stir until fully dissolved, and remove insoluble matter by centrifugation at a centrifugal force of 5000 g;

[0057] (2) Preparation of sunflower oil solution: Dissolve 25mg DPPC in ethanol, remove ethanol by rotary evaporation and form a lipid film in the rotary evaporation bottle, add 9.975g sunflower oil and stir slowly at 50°C for 2h until DPPC is completely dissolved ;

[0058] (3) Preparation of emulsion: 90 mL of polyethylene glycol aqueous solution in the above (1) and 10 g of the sunflower oil solution obtained in (2) are mixed uniformly, then sheared at 13500 rpm for 90 s with a high-speed shearing machine, and homogenized by a high-pressure homogenizer Twice, the first homogenization pressure is 35MPa, and the second homogenization pressure is 10MPa to form an emulsion;

[0059] (4) Preparation of freeze-dried powder: After freezing the emu...

Embodiment 2

[0064] (1) Preparation of polyethylene glycol aqueous solution: mix 15g polyethylene glycol with 85mL ultrapure water, stir until fully dissolved, and remove insoluble matter by centrifugation at a centrifugal force of 5000g;

[0065] (2) Preparation of sunflower oil solution: Dissolve 30mg DPPC in ethanol, remove the ethanol by rotary evaporation and form a lipid film in the rotary evaporation bottle, add 9.970g sunflower oil and stir slowly at 50°C for 2h until DPPC is completely dissolved ;

[0066] (3) Preparation of emulsion: 85 mL of polyethylene glycol aqueous solution in the above (1) and 15 g of the sunflower oil solution obtained in (2) are mixed evenly, then sheared at 15000 rpm for 90 seconds with a high-speed shearing machine, and homogenized by a high-pressure homogenizer Twice, the homogeneous pressure for the first time is 30MPa, and the homogeneous pressure for the second time is 15MPa to form an emulsion;

[0067] (4) Preparation of freeze-dried powder: Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com