Preparation method of amorphous iron oxyhydroxide/bismuth vanitate composite photocatalytic material

A kind of bismuth vanadate catalytic material, composite photocatalytic technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

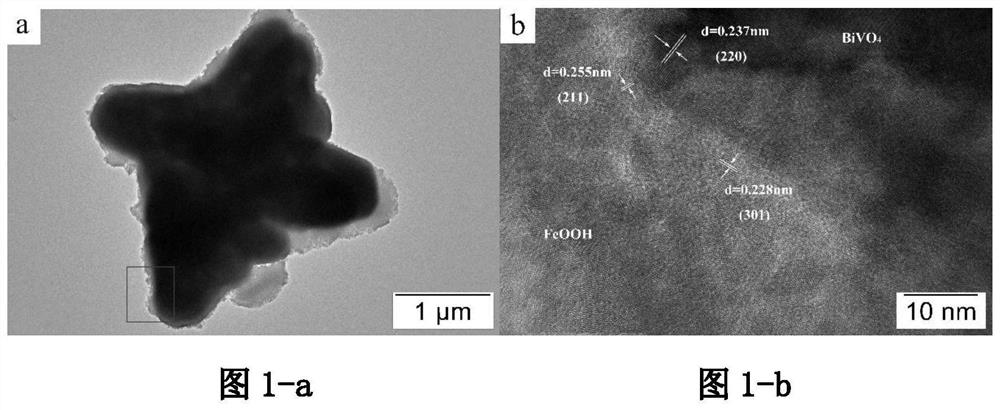

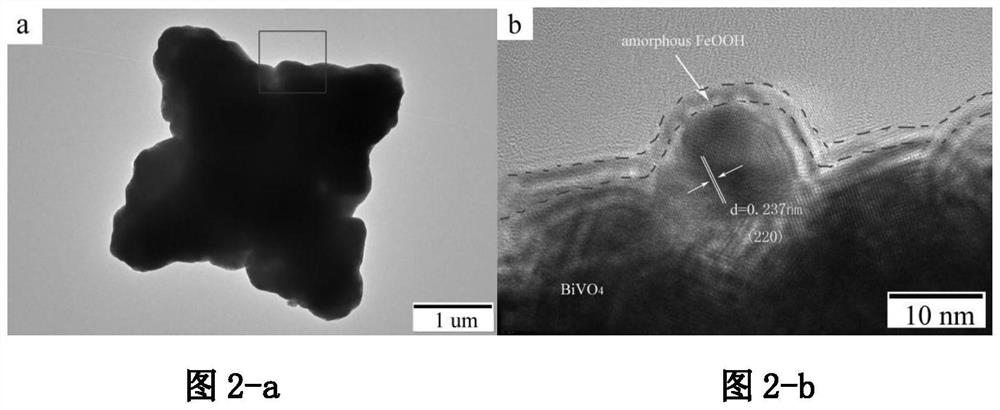

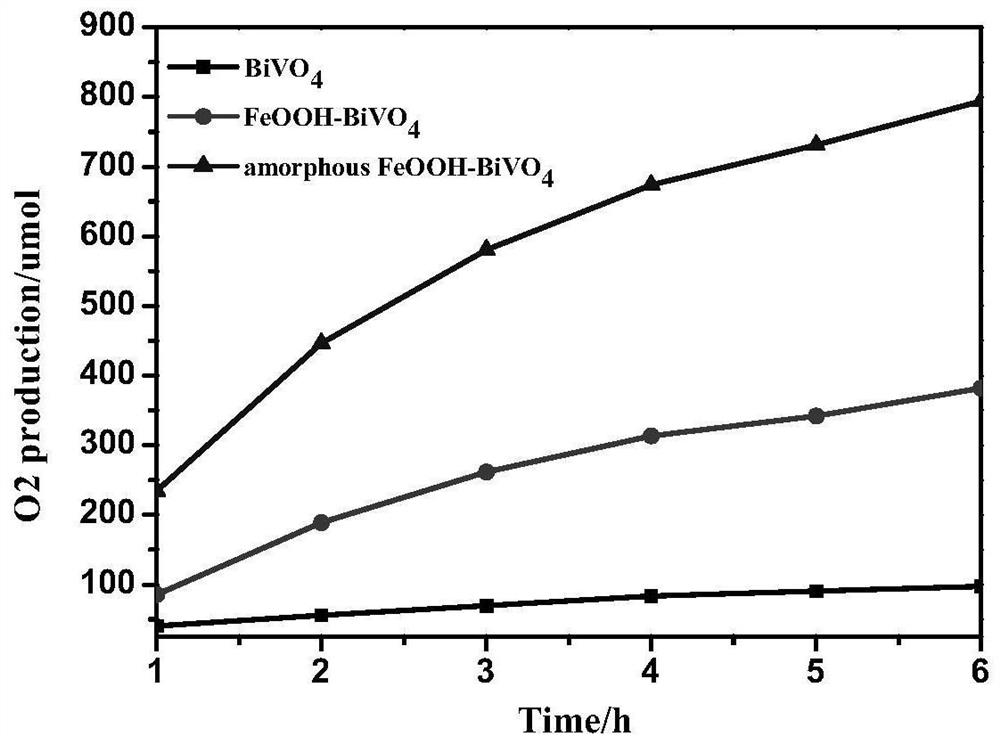

[0033] Weigh 5 mmol Bi(NO3)3·5H2O (analytical grade) and dissolve in 5 mL of 3 mol·L-1 HNO3 solution and 15 mL of ethylene glycol mixed solution to prepare A solution, weigh 5 mmol NH4VO3 (analytical Pure) was dissolved in 20 mL of hot water added with 0.4 g of sodium dodecylbenzenesulfonate (SDBS) to prepare solution B. After each stirring at room temperature for 30 min, solution A was added dropwise to solution B, the pH value was adjusted to 6 using NaOH solution with a concentration of 1 mol L-1, and the mixed solution was stirred for 30 min to obtain the BiVO4 catalyst precursor. Transfer the obtained solution into a 100 mL autoclave lined with polytetrafluoroethylene, seal it, put it in an oven, conduct a hydrothermal reaction at 200 °C for 22 hours, cool it down to room temperature naturally, and wash it repeatedly with distilled water and absolute ethanol for more than 3 times , Dry at a constant temperature at 60°C for 6h, and grind it with a mortar after cooling to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com