Bismuth vanadate/silver chromate heterojunction photocatalyst as well as preparation method and application thereof

A photocatalyst and heterojunction technology, applied in the field of photocatalysis, can solve the problems of increased catalyst cost, poor quality of heterojunction, weak combination, etc., to achieve improved photocatalytic activity and stability, high interface binding degree, enhanced The effect of photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

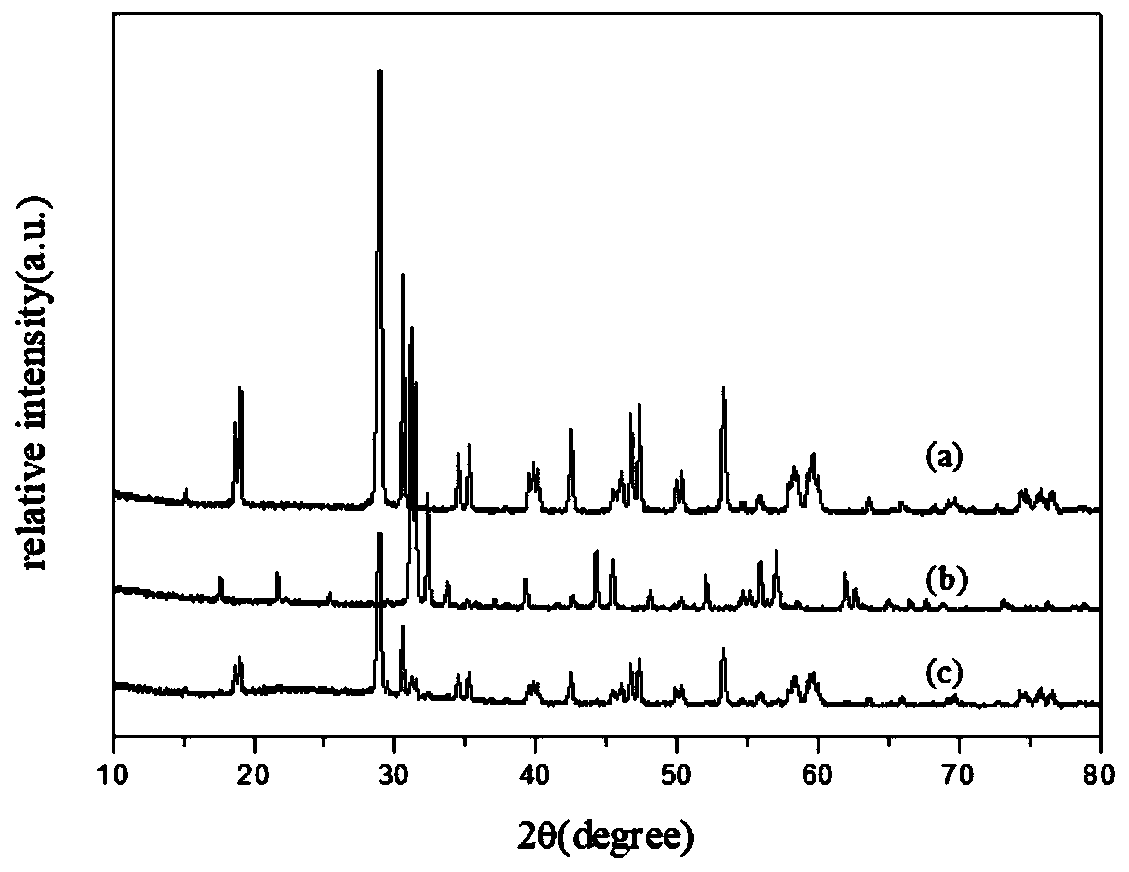

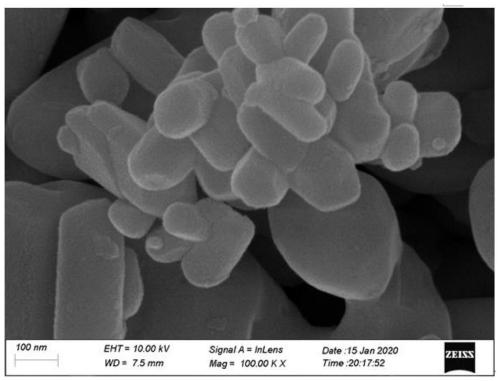

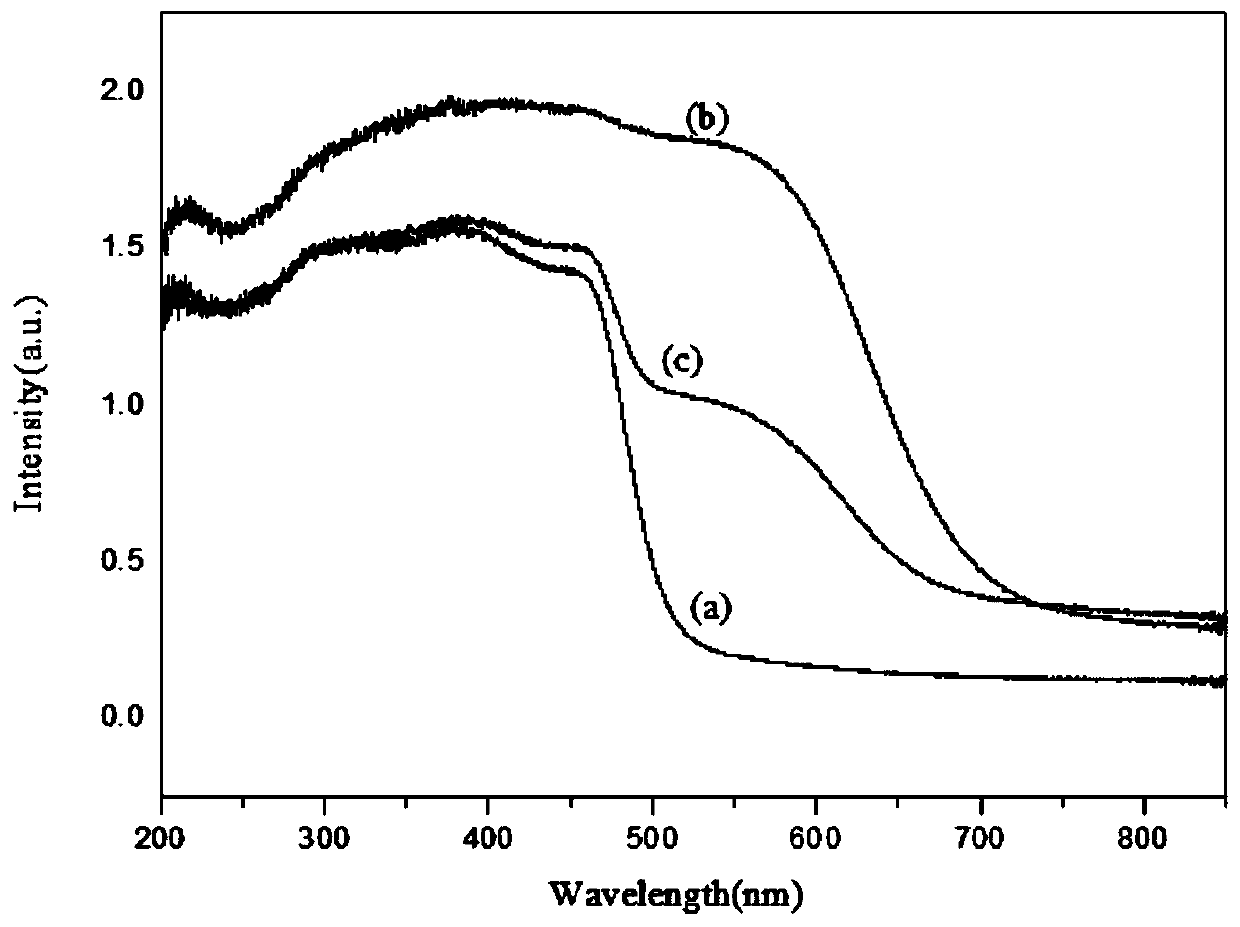

[0027] A preparation method of bismuth vanadate / silver chromate heterojunction photocatalyst, comprising the following steps:

[0028] S1: Preparation of bismuth vanadate by hydrothermal method:

[0029] a. Take 2.5mmol Bi(NO 3 ) 3 ·5H 2 Add O to 50mL of 2mol / L dilute nitric acid solution / take 2.5mmol NH 4 VO 3 Add it to 50mL of 2mol / L ammonia solution, stir for 0.5h to promote its complete dissolution, and obtain clear and transparent Bi(NO 3 ) 3 -HNO 3 / NH 4 VO 3 -NH 3 ·H 2 O solution; get 0.5g sodium dodecylsulfonate (SDS), join in 20mL high-purity water, stir and promote its complete dissolution, obtain SDS aqueous solution;

[0030] b. to Bi(NO 3 ) 3 -HNO 3 Add SDS aqueous solution drop by drop to the solution, after mixing evenly, slowly add NH 4 VO 3 -NH 3 ·H 2O solution, stirred for 0.5h, then adjusted the pH to 7.0 with 2mol / L ammonia solution, and continued to stir for 2h, then transferred the reaction solution to a high-pressure reactor, then hydro...

Embodiment 2

[0035] A preparation method of bismuth vanadate / silver chromate heterojunction photocatalyst, comprising the following steps:

[0036] S1: Preparation of bismuth vanadate by hydrothermal method: same as Example 1;

[0037] S2: Preparation of heterojunction photocatalyst:

[0038] a. Accurately weighed 0.5g BiVO 4 , 0.2248g AgNO 3 and 0.1285g K 2 CrO 4 , the AgNO 3 、K 2 CrO 4 Respectively dubbed into 100mL solution;

[0039] b. Weigh 0.5g BiVO 4 Add 100mL distilled water, after ultrasonic dispersion, under the condition of magnetic stirring, add 100mL AgNO 3 solution, and continue to stir for 12h, then slowly drop 100mL K 2 CrO 4 Solution, a brick-red precipitate was generated, and continued to stir for reaction 1, then let the precipitate stand for 4 hours, centrifuged at a speed of 4500r / min to separate it from water, and washed the lower precipitate with water 6 times to remove unreacted reagents and impurities, 80 ℃ vacuum drying for 6h to obtain BiVO 4 BiVO wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com