Non-equidistant texture finishing abrasion-reducing turning blade

A non-isometric and finishing technology, applied in metal processing equipment, cutting tools for lathes, turning equipment, etc., can solve problems such as high cutting temperature, tool wear, and large cutting force, and achieve lower cutting temperature and lower cutting speed. Force, enhance the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

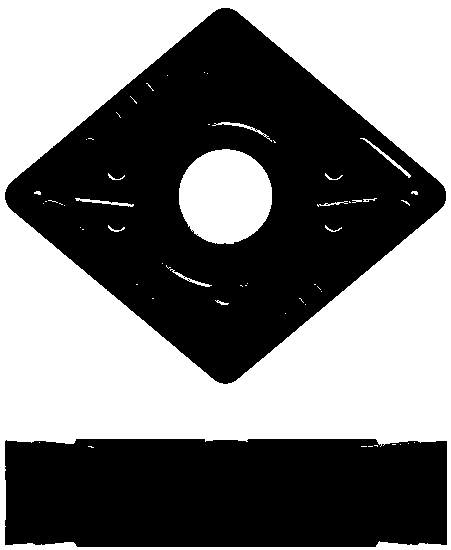

[0015] figure 1 It is a three-dimensional diagram of non-equidistant texture finish machining and anti-friction turning blades. The main body of the blade is designed as an 80° rhombic turning blade with a radius of 0.8mm and the material is cemented carbide.

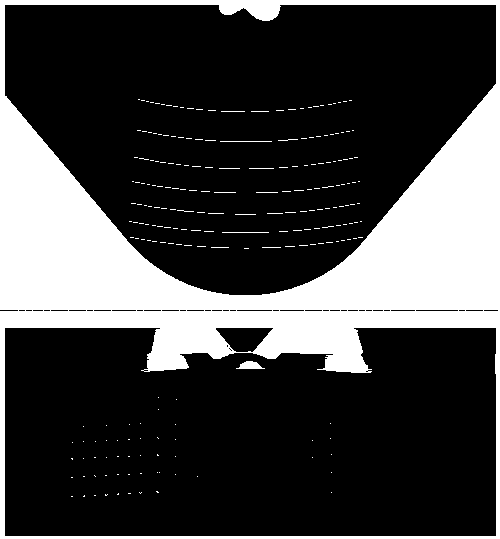

[0016] figure 2 It is a three-dimensional enlarged view of the micro-texture, which are the enlarged views of the micro-texture of the rake face and the micro-texture of the flank respectively.

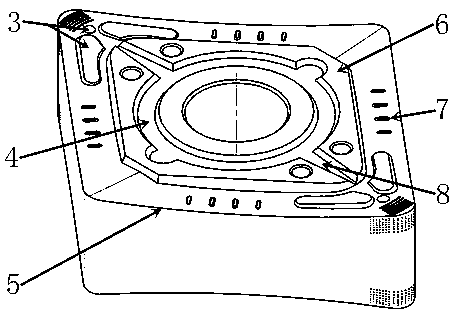

[0017] exist image 3 Among them, there are non-equidistant arc-shaped groove micro-textures (1) distributed on the rake face. The groove widths of the micro-textures are different, and its size conforms to the arithmetic sequence with the first term being 20 μm and the tolerance being 5 μm. The texture spacing size conforms to the arithmetic sequence whose first term is 60 μm and the tolerance is 10 μm. The distribution mode is that the closer to the cutting edge, the denser the texture, and the smaller the texture groove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com