Reinforcing method for bonding performance of composite components

A composite material component and bonding technology, which is applied in the field of composite material manufacturing, can solve problems affecting the bonding performance of composite material components, affecting the personal safety of operators, and contamination of components to be bonded, so as to avoid contamination or damage to components. Damage, simplification of operation process, low interference of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

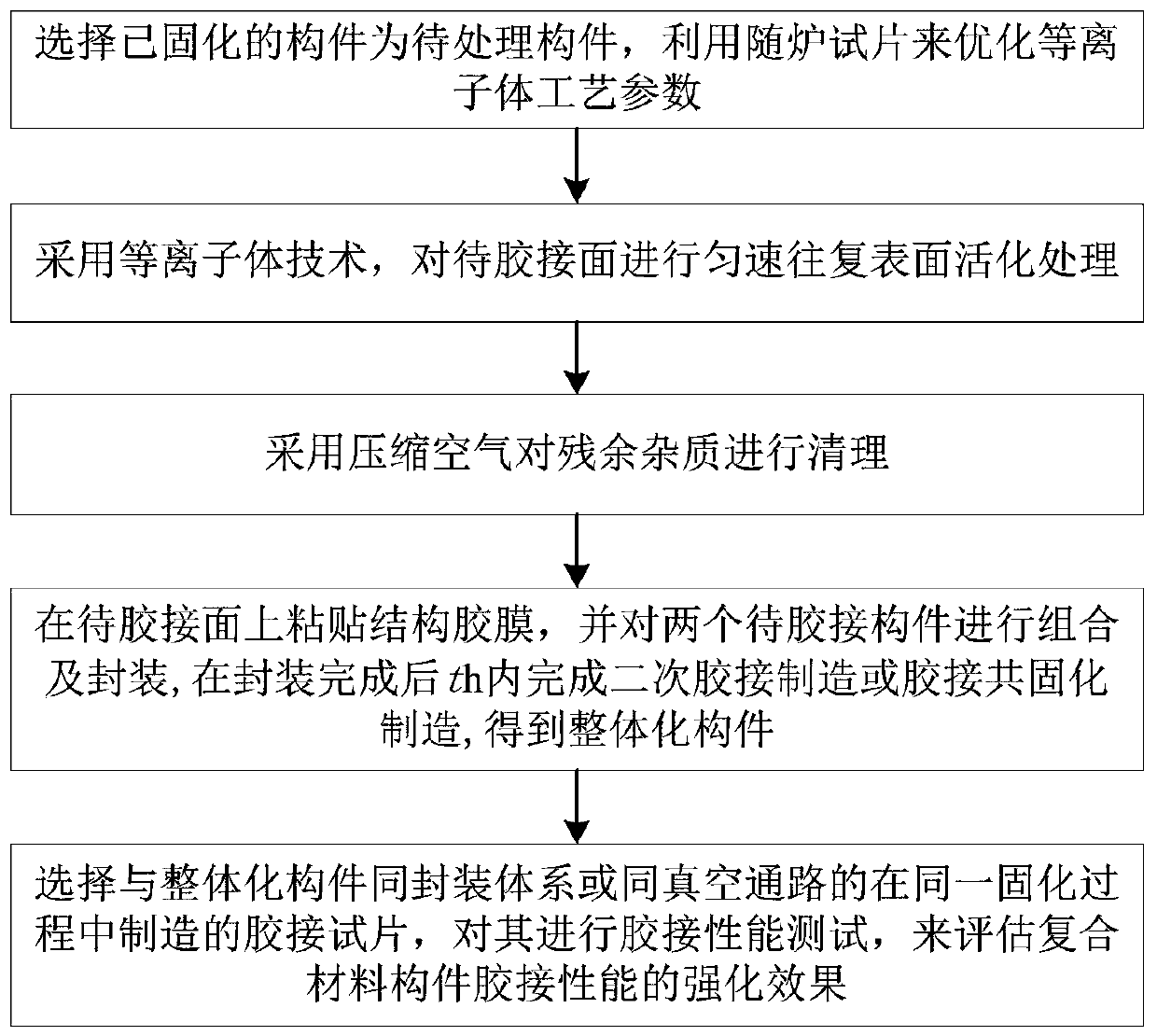

[0022] Such as figure 1 Shown is a flow chart of the method for strengthening the bonding performance of composite material components of the present invention. The method for strengthening the bonding performance of a composite material component of the present invention, the bonding of the composite material component is bonding between a cured composite material component and an uncured composite material component or between two cured composite material components Bonding or bonding between the solidified composite material component and the metal material component, is characterized in that, comprises the following steps:

[0023] Step 1: Select the cured component in the bonding of the composite material component as the component to be treated, use the furnace test piece of the component to be treated to optimize the plasma processing power, processing time and processing distance, and obtain the components suitable for processing Plasma process parameters for surface ...

Embodiment 2

[0040] The difference between this second embodiment and the above-mentioned first embodiment is that the bonding of the composite material components is composite material / metal laminate structure bonding, specifically the cured aramid fiber reinforced resin matrix composite material (914 / 5222A) component Bonding with aluminum alloy (2B06) components; in step 1, the components to be treated are cured aramid fiber-reinforced resin-based composite components and aluminum alloy components; using cured aramid fiber-reinforced resin-based composite materials The furnace test piece of the component was used to optimize the plasma treatment power, treatment time and treatment interval, and the plasma process parameters suitable for the surface activation treatment of the cured aramid fiber reinforced resin matrix composite component were obtained as treatment power 3000W, treatment The time is 10s, and the treatment interval is 3mm; the treatment power, treatment time and treatment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com