Porous ceramic material with composite function as well as preparation method thereof

A composite function and ceramic material technology, which is applied in ceramic products, separation methods, chemical instruments and methods, etc., can solve the problems of endangering human health, easy dryness, single function, etc., achieve high-quality healthy life, absorb and decompose harmful gases , the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] As a further embodiment, the preparation method of the composite functional sol comprises the following steps:

[0041] The step of preparing an acidic aqueous solution: adding an acid to the aqueous solution to obtain an acidic aqueous solution;

[0042] Steps for preparing the titanium solution: dispersing the titanium-containing salt in absolute ethanol to obtain a titanium solution;

[0043] The mixing step: slowly add the obtained titanium solution into the acidic aqueous solution under stirring at a low temperature of 5-40°C to obtain a titanium-containing aqueous solution;

[0044] Steps of adding functional additives: add functional additives to the obtained titanium-containing aqueous solution under stirring and ultrasonic conditions, and age under stirring conditions at 5-40°C for 1-5 days to obtain a composite functional sol; stirring during the aging process can Prevent sol delamination from affecting uniformity.

[0045] Steps for low-temperature storage:...

Embodiment 1

[0056] Example 1 A multi-level porous ceramic material with composite functions of adsorption and decomposition of harmful gases + dehumidification and humidity control + deodorization

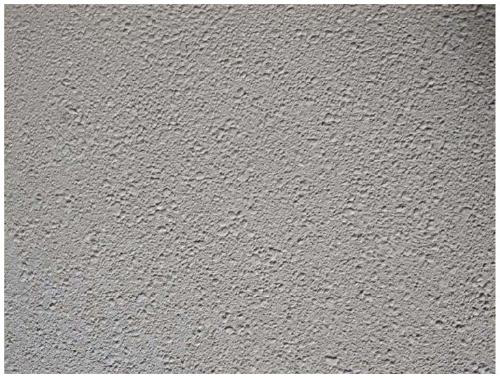

[0057] The multi-level porous ceramic material with composite function is composed of an inorganic multi-level porous matrix and a composite functional film that sprays a composite functional sol on the surface of the inorganic multi-level porous matrix; the composite functional film is composed of titanium dioxide, functional additives (zinc oxide nano particles / clusters) and acidic aqueous solution; the functional additive is selected from zinc oxide nanoparticles / clusters.

[0058] The preparation method of the hierarchical porous ceramic material comprises the following steps:

[0059] The steps of preparing the inorganic multi-level porous matrix: the inorganic multi-level porous matrix is made of inorganic solid powder 1 and inorganic solid powder 2 with a weight ratio of 3:1 as raw ...

Embodiment 2

[0062] Example 2 A multi-level porous pottery with composite functions of adsorption and decomposition of harmful gases + dehumidification and humidity control + deodorization + antibacterial porcelain material

[0063] The hierarchical porous ceramic material with composite functions, such as figure 1 As shown, it consists of an inorganic hierarchical porous substrate and a composite functional film that sprays a composite functional sol on the surface of the inorganic porous substrate; the composite functional film is prepared from titanium dioxide, functional additives, and an acidic aqueous solution; the functional additive is selected from From the composition of zinc oxide nanoparticles / clusters and silver halide nanoparticles / clusters, the volume ratio of zinc oxide nanoparticles / clusters and silver halide nanoparticles / clusters is 4:1.

[0064] The preparation method of the hierarchical porous ceramic material comprises the following steps:

[0065] The steps of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com