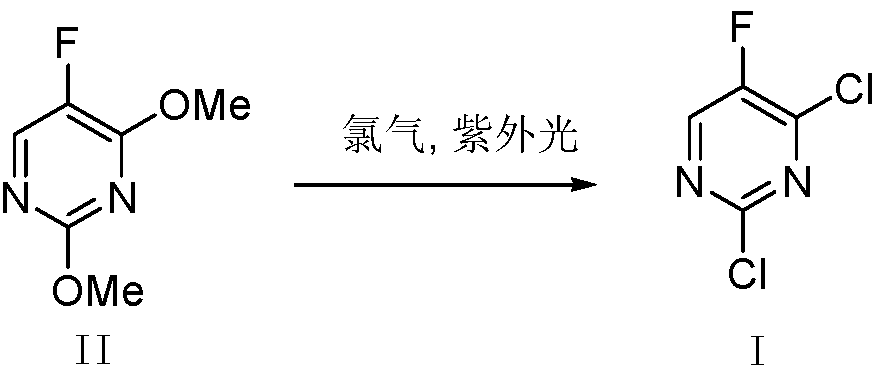

Method for preparing 2,4-dichloro-5-fluoropyrimidine through ultraviolet photocatalytic reaction

A catalytic reaction, fluoropyrimidine technology, applied in the field of medicine and chemical industry, can solve problems such as environmental pollution, and achieve the effects of easy operation, low cost, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The present invention is a method for preparing 2,4-dichloro-5-fluoropyrimidine by ultraviolet photocatalytic reaction, comprising figure 1 As indicated, under ice bath at 0°C, dissolve 15.8 g of 2,4-dimethoxy-5-fluoropyrimidine (II) in 200 ml of dichloroethane solution with stirring, add 0.32 g of sulfuryl chloride, and use high-energy xenon gas to Light the light source, adjust the wavelength of ultraviolet light to 220nm and irradiate for 10 minutes, slowly introduce chlorine gas, control the temperature of the reaction solution at 20-30°C, and the reaction lasts for 12 hours, stop the chlorine, and obtain the reaction solution; add an equal volume of 2,4-dichloro-5-fluoro Pyrimidine (I) 158 g, yield 95%.

Embodiment 2

[0015] A method for preparing 2,4-dichloro-5-fluoropyrimidine by ultraviolet photocatalytic reaction of the present invention is to dissolve 15.8 grams of 2,4-dimethoxy-5-fluoropyrimidine in an ice bath at 0°C under stirring Add 0.7 g of sulfonyl chloride to 200 ml of chloroform solution, use a high-energy xenon lamp light source, adjust the wavelength of ultraviolet light to 260 nm and irradiate for 30 minutes, then slowly introduce chlorine gas, control the temperature of the reaction solution at about 20 ° C, and the reaction lasts for 12 hours. , stop logical chlorine, obtain reaction solution, add equal volume ice water in reaction solution, separate liquid after stirring, organic phase washes with 50 milliliters of 5% sodium carbonate aqueous solution, then washes with 50 milliliters of water, after the organic phase is dried, concentrate under reduced pressure, The pale yellow solid product 2,4-dichloro-5-fluoropyrimidine was 163 grams, and the yield was 98%.

Embodiment 3

[0017] A method for preparing 2,4-dichloro-5-fluoropyrimidine by ultraviolet photocatalytic reaction of the present invention is to dissolve 15.8 grams of 2,4-dimethoxy-5-fluoropyrimidine in an ice bath at 0°C under stirring Add 0.5 g of sulfuryl chloride to 200 ml of dichloroethane solution, use a high-energy xenon lamp light source, adjust the wavelength of ultraviolet light to 300 nm and irradiate for 30 minutes, then slowly introduce chlorine gas, control the temperature of the reaction solution at about 20 ° C, and the reaction continues After 12 hours, stop feeding chlorine to obtain a reaction solution, add an equal volume of ice water to the reaction solution, separate after stirring, wash the organic phase with 50 milliliters of 5% sodium carbonate aqueous solution, then wash with 50 milliliters of water, dry the organic phase and reduce Concentrated under reduced pressure, the light yellow solid product 2,4-dichloro-5-fluoropyrimidine was 151 grams, and the yield was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com