An alumina nanoparticle/polyimide based energy-storage medium and a preparing method thereof

A nano-alumina, polyimide-based technology, applied in the field of dielectric composite materials, can solve the problems of low energy storage density of polyimide, and achieve the effects of excellent mechanical properties, high relative permittivity, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing an alumina nanoparticle / polyimide-based energy storage medium, the steps are as follows:

[0031] Step 1, preparing alumina nanoparticles:

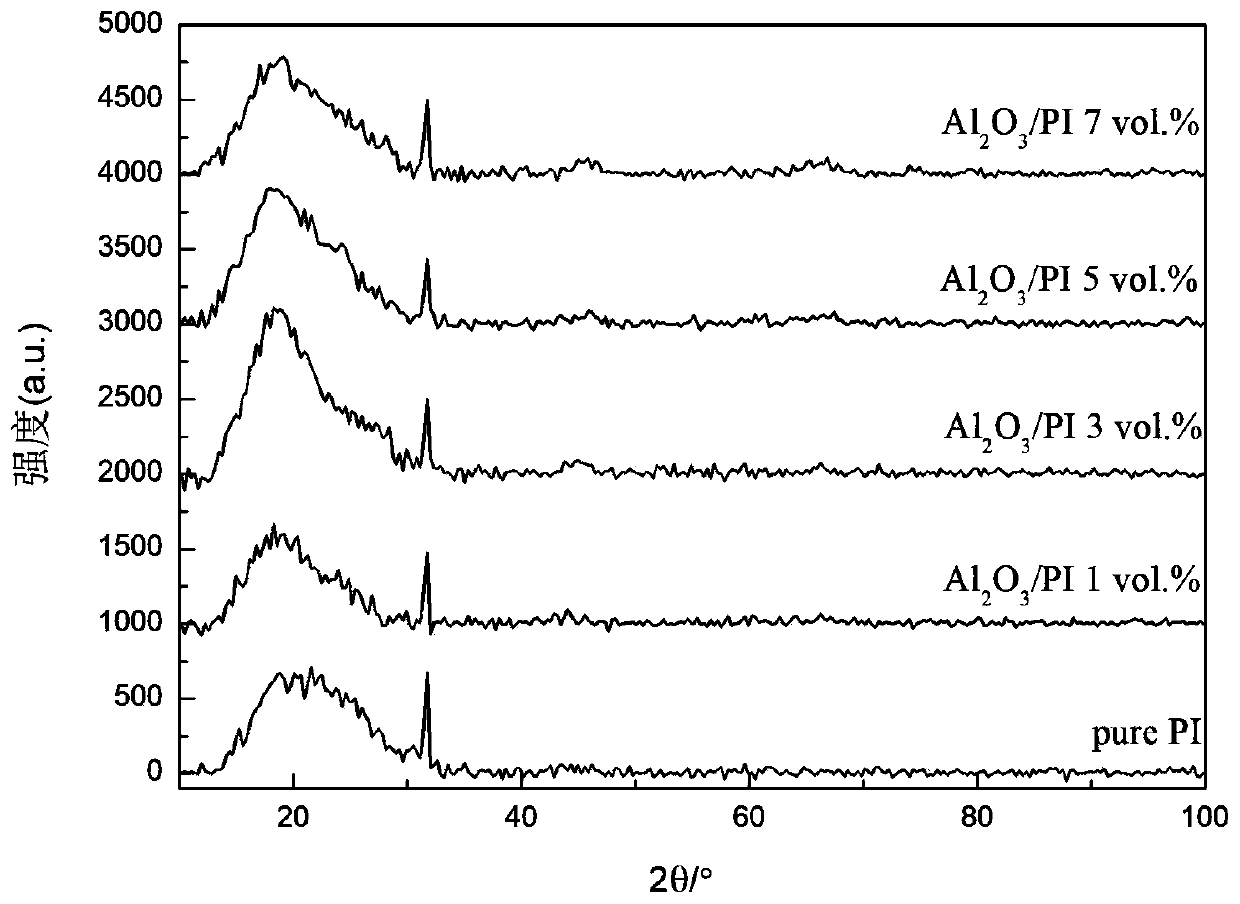

[0032] Mixing aluminum nitrate, deionized water and absolute ethanol according to a certain mass-volume ratio, drying at a certain temperature, and performing ball milling, calcination and nano-sanding treatment on the obtained powder in sequence to obtain alumina nanoparticles;

[0033] Step 2. Prepare precursor solution:

[0034] Prepare the alumina nanoparticles, N,N-dimethylformamide, pyromellitic anhydride and 4,4-diaminodiphenyl ether prepared in step 1 according to a certain mass volume ratio, and prepare the alumina nanoparticles, homogeneous Mix pyromellitic anhydride and N,N-dimethylformamide and ultrasonically disperse for a certain period of time, add 4,4-diaminodiphenyl ether in batches during the stirring process under ice-water bath conditions, and obtain a mixed colloidal precursor after full...

Embodiment 2

[0038] A method for preparing an alumina nanoparticle / polyimide-based energy storage medium, the steps are as follows:

[0039] Step 1, preparing alumina nanoparticles:

[0040] Mix aluminum nitrate, deionized water and absolute ethanol according to the mass volume ratio of 1g:1ml:10ml and stir evenly, then pour it into a petri dish, place it in an oven and dry it at 80°C for 8-12h; into a ball mill tank, add absolute ethanol with a volume of 60% of the ball mill tank volume, ball mill at a speed of 600-800r / min for 12 hours, and dry the obtained slurry in a vacuum oven at 80°C for 8 hours; put the dried powder into a In the Furnace, at a heating rate of 2°C / min, rise to 900°C in 450 minutes, keep warm at 900°C for 1 hour and then cool down to room temperature; add the calcined powder into the container of the nano sand mill, and add 60% of the volume of the sand mill Anhydrous ethanol, after sanding at a speed of 2500r / min for 4h, drying in a vacuum oven at 80°C for 8h to ob...

Embodiment 3

[0046] A method for preparing an alumina nanoparticle / polyimide-based energy storage medium, the steps are as follows:

[0047] Step 1, preparing alumina nanoparticles:

[0048] Mix aluminum nitrate, deionized water and absolute ethanol according to the mass volume ratio of 1g:1ml:10ml and stir evenly, then pour it into a petri dish, place it in an oven and dry it at 80°C for 8-12h; into a ball mill tank, add absolute ethanol with a volume of 60% of the ball mill tank volume, ball mill at a speed of 600-800r / min for 12 hours, and dry the obtained slurry in a vacuum oven at 80°C for 8 hours; put the dried powder into a In the Furnace, at a heating rate of 2°C / min, rise to 900°C in 450 minutes, keep warm at 900°C for 1 hour and then cool down to room temperature; add the calcined powder into the container of the nano sand mill, and add 60% of the volume of the sand mill Anhydrous ethanol, after sanding at a speed of 2500r / min for 4h, drying in a vacuum oven at 80°C for 8h to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com