Chemical method to improve film adhesion and achieve double-layer compounding of dielectric films

A double-layer composite, dielectric thin-film technology, applied in thin-film/thick-film capacitors, components of fixed capacitors, multilayer capacitors, etc., can solve problems such as high dielectric breakdown strength, limited usage scenarios, and limited practicability , to achieve the effect of improving energy storage density, improving use value, and improving interface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

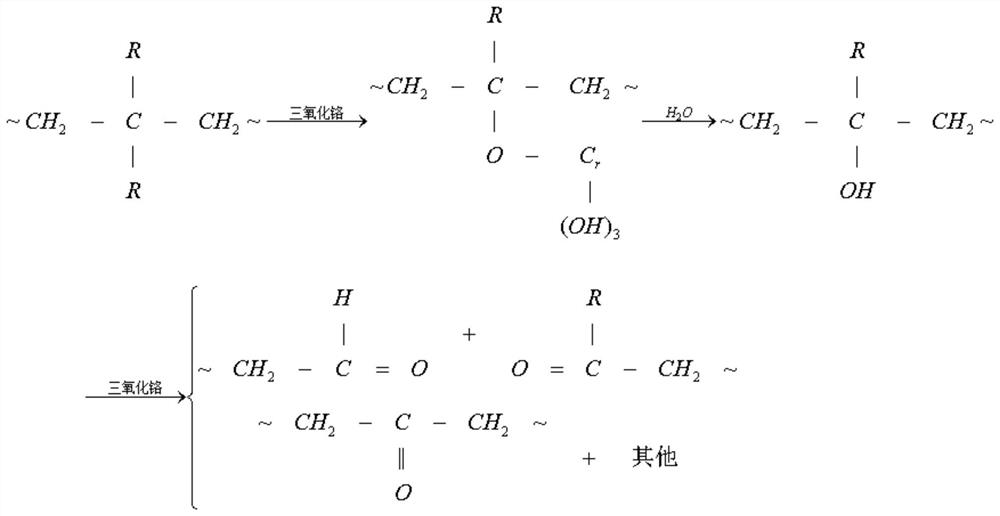

[0035] This embodiment provides a method for chemically improving film adhesion to realize double-layer compounding of dielectric films, including the following steps:

[0036] (1.1) Ultrasonic cleaning of the beakers, measuring cylinders, reagent bottles, rotors and glass plates used in the reaction with detergents; during the cleaning process, use detergent to clean and then use deionized water, acetone and alcohol to ultrasonically clean for 15 minutes.

[0037] (1.2) Use a graduated cylinder to measure deionized water and pour it into a clean beaker, weigh the analytically pure chromium trioxide with a ten-thousandth balance, put it into the beaker, put it into the rotor, and put the beaker on the electric magnetic stirrer , fully stirred for 10 minutes to fully dissolve chromium trioxide in deionized water, and let it stand for use. The concentration of the configured chromium trioxide aqueous solution is 15%.

[0038] (2.1) Clean the ceramic tray and soft brush with det...

Embodiment 2

[0044] This embodiment provides a method for chemically improving film adhesion to realize double-layer compounding of dielectric films, including the following steps:

[0045](1.1) Clean the beakers, measuring cylinders, reagent bottles, rotors and glass plates used in the reaction with detergent ultrasonically; during the cleaning process, use detergent to clean and then use deionized water, acetone and alcohol to ultrasonically clean for 30 minutes.

[0046] (1.2) Use a graduated cylinder to measure deionized water and pour it into a clean beaker, weigh the analytically pure chromium trioxide with a ten-thousandth balance, put it into the beaker, put it into the rotor, and put the beaker on the electric magnetic stirrer , fully stirred for 20 minutes to fully dissolve chromium trioxide in deionized water, and let it stand for use. The concentration of the configured chromium trioxide aqueous solution is 30%.

[0047] (2.1) Clean the ceramic tray and soft brush with deterge...

Embodiment 3

[0053] This embodiment provides a method for chemically improving film adhesion to realize double-layer compounding of dielectric films, including the following steps:

[0054] (1.1) Clean the beakers, measuring cylinders, reagent bottles, rotors and glass plates used in the reaction with detergent ultrasonically; during the cleaning process, use detergent to clean and then use deionized water, acetone and alcohol to ultrasonically clean for 20 minutes.

[0055] (1.2) Use a graduated cylinder to measure deionized water and pour it into a clean beaker, weigh the analytically pure chromium trioxide with a ten-thousandth balance, put it into the beaker, put it into the rotor, and put the beaker on the electric magnetic stirrer , fully stirred for 15 minutes to fully dissolve chromium trioxide in deionized water, and let it stand for use. The concentration of the configured chromium trioxide aqueous solution is 20%.

[0056] (2.1) Clean the ceramic tray and soft brush with deterg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com