A kind of non-polar polymer negative Poisson's ratio foam material and preparation method thereof

A technology of non-polar polymer and negative Poisson's ratio, applied in the field of non-polar polymer negative Poisson's ratio foam material and preparation thereof, can solve the problems of unfavorable large-scale production, cumbersome preparation process, low preparation efficiency and the like, Achieve the effect of low production cost, simple process and good notch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

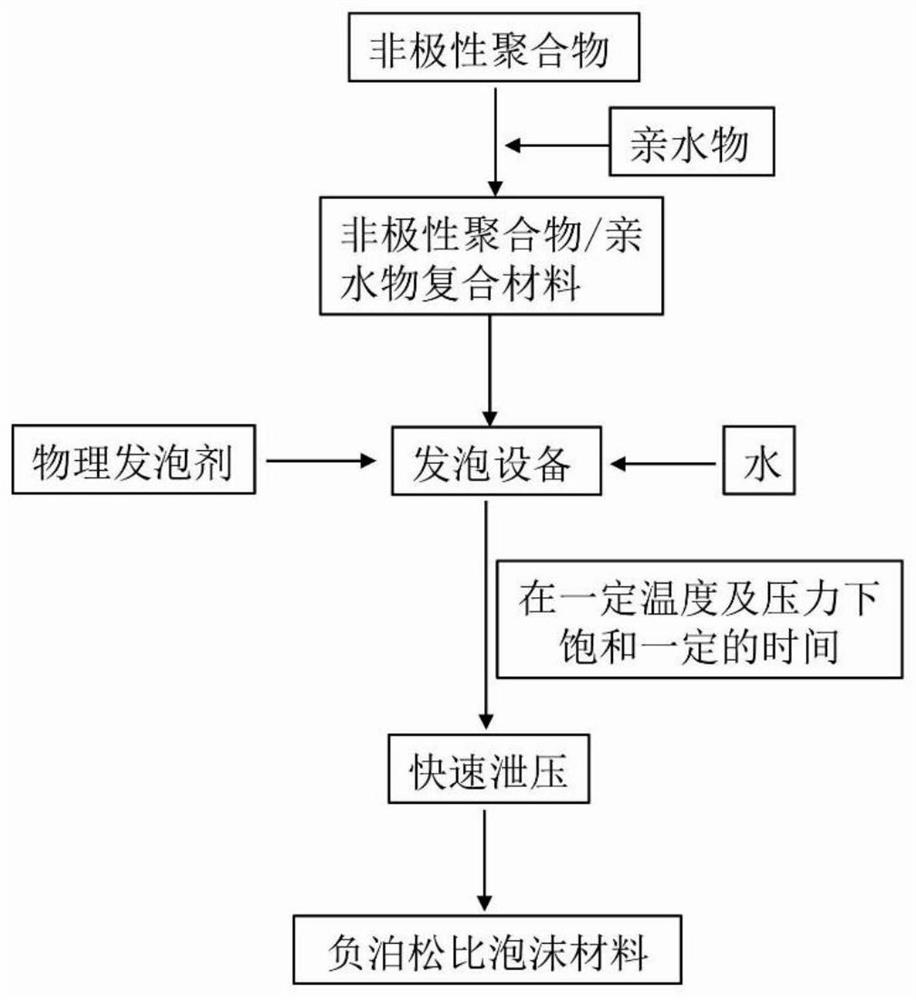

[0039] Such as figure 1 Shown, the preparation method of nonpolar polymer negative Poisson's ratio foam material of the present invention, the steps are as follows:

[0040] Step 1. Composite the non-polar polymer and the hydrophilic substance first, and form it to obtain the composite material;

[0041] Step 2. Put the composite material obtained in Step 1 into the foaming equipment, introduce physical foaming agent and water, and at the saturation temperature of 80-180°C and the saturation pressure of 3-25MPa, the saturation time is more than 0.5h, and the rapid release Press to obtain a non-polar polymer foam material with negative Poisson's ratio.

[0042] In the above technical scheme, in the process of compounding non-polar polymers and hydrophilic substances, those skilled in the art can also compound additives in the system according to experience and needs, specifically calcium carbonate powder, talc powder, wollastonite powder, Silica powder, alumina, aluminum hydr...

Embodiment 1

[0057] First, add polypropylene (Daqing Petrochemical, T30S) and sodium chloride into the twin-screw extruder according to the mass ratio of 98:2. The temperature in the mixing section is 200°C, the speed is 200 rpm, extruded and granulated, and then the injection molding machine is used to into 10×10×10mm 3 The cubic composite material; then the composite material is placed in 180 ℃, 3MPa CO 2 After 10 hours in the foaming equipment with water, the pressure is released to normal pressure, and the pressure release speed is 2MPa / s. During the process of pressure release and foaming, the composite material is discharged out of the foaming equipment with the pressure release gas to complete foaming, and polypropylene is obtained. Negative Poisson's ratio foam.

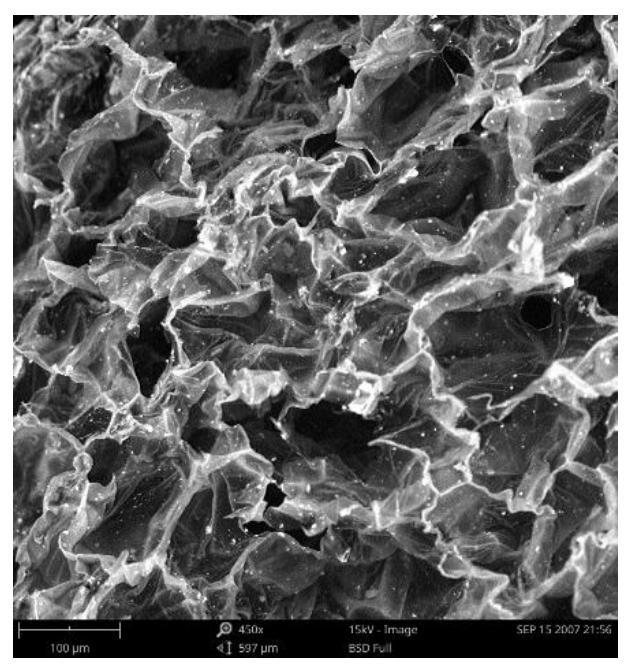

[0058] After testing, the foam material has a cell structure with "concave corners", and the SEM photos are as follows figure 2 As shown; the Poisson's ratio of the material is tested according to the GB / T1040.1-2006 s...

Embodiment 2

[0060] First, high-density polyethylene (Fushun Petrochemical, FHC7260) and sodium stearate are added to the twin-screw extruder at a mass ratio of 96:4. The temperature in the mixing section is 200°C, extruded and granulated, and then made into 50×50 ×20mm 3 The sheet composite material, the temperature of the injection molding machine is 195 ° C; then the composite material is placed in 130 ° C, 25 MPa CO 2After 0.5h in the foaming equipment with water, the pressure is released to normal pressure at a speed of 50MPa / s. During the process of pressure relief and foaming, the composite material remains in the foaming equipment to complete foaming, and then the foaming equipment is opened Take it out to obtain polyethylene negative Poisson's ratio foam material.

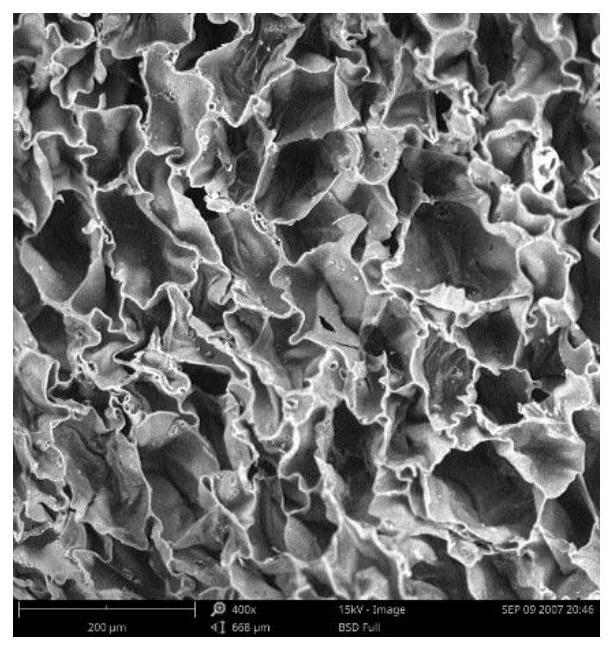

[0061] After testing, the foam material has a cell structure with "concave corners", and the SEM photos are as follows image 3 As shown; the Poisson's ratio of the material is tested according to the GB / T1040.1-2006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com