Multi-hydrogen acid system suitable for reservoir plugging-removing acidification and preparing method thereof

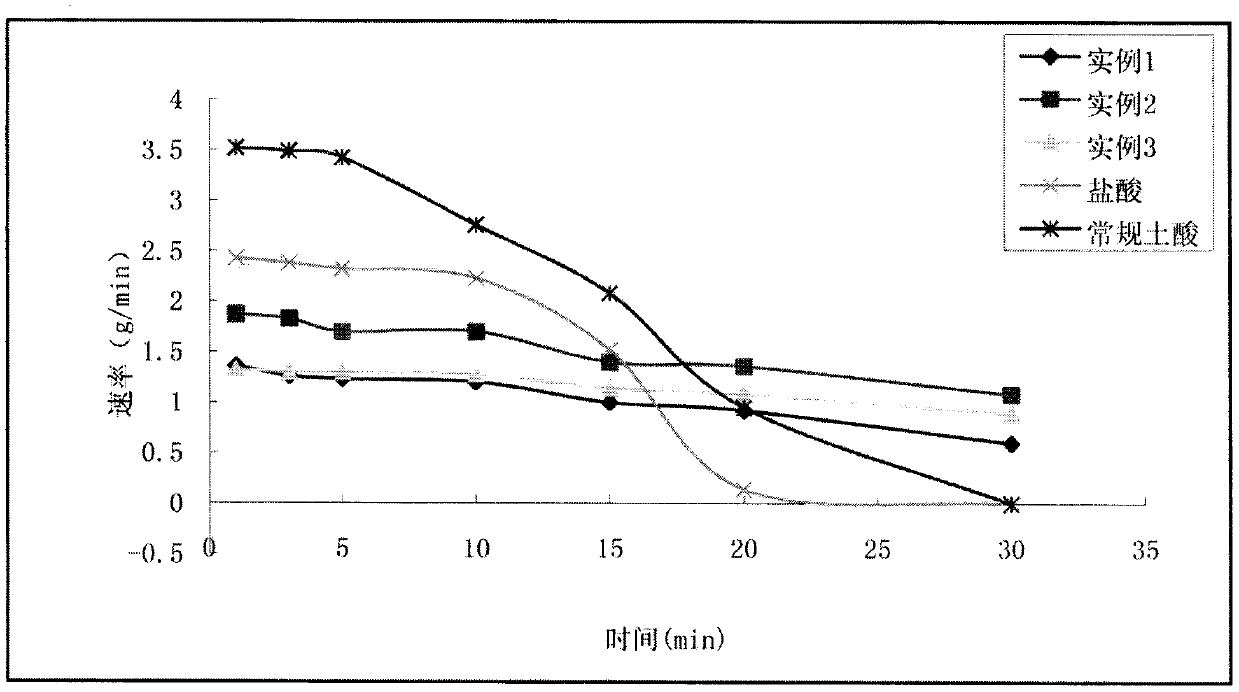

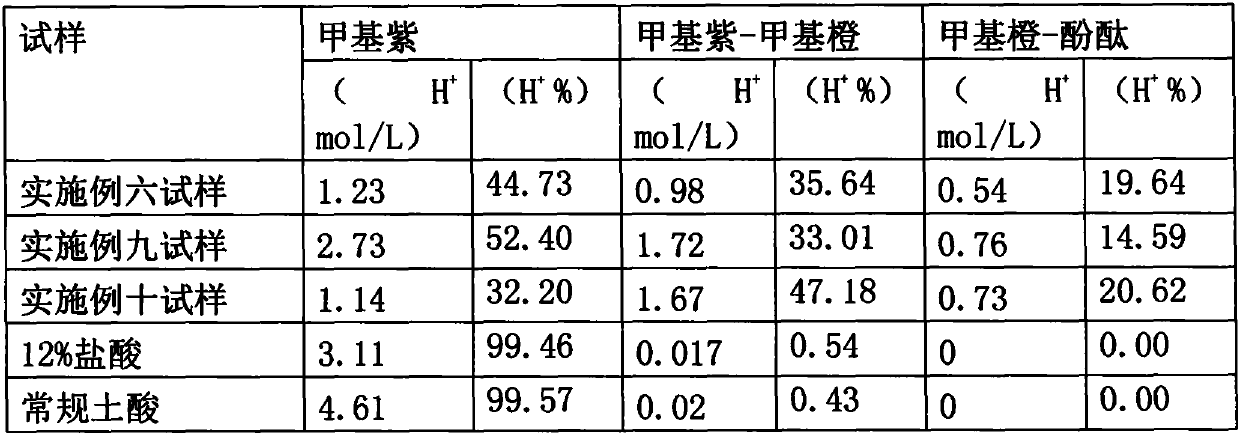

A multi-hydrogen acid and system technology, applied in the field of acidizing fluid, can solve the problems of slow pressure drop, long construction time, difficulty in satisfying deep formation plugging removal, etc., and achieve the effect of strong absorption and supply capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A method for preparing a polyhydric acid system suitable for reservoir deblocking acidification, the preparation method comprising the following steps:

[0020] Step 1: Prepare the multi-effect additive: add the water in the multi-effect additive into the container with stirring, start the stirring device, add fluorocarbon surfactant, potassium amine triacetate and potassium chloride in sequence, and stir the above materials evenly, Made into multi-effect additives;

[0021] Step 2: Preparation of corrosion inhibitor: place propynyl alcohol in a container, slowly add benzylpyridine to make corrosion inhibitor; the way of slow addition is stirring while adding, until the addition of benzylpyridine is complete;

[0022] Step 3: Add water into the container with stirring, start the stirring device, and at normal temperature and pressure, add the corrosion inhibitor, active agent, expansion agent configured in step 2, multi-effect additive prepared in step 1, multi- Hydrog...

Embodiment 1

[0025] A polyhydric acid system suitable for reservoir deblocking and acidification, comprising the following raw materials in parts by weight: hydrochloric acid: 30 parts, polyhydric acid: 7 parts, multi-effect additive: 3 parts, shrinking agent: 2 parts , active agent: 1 part, initiator: 3 parts, corrosion inhibitor: 2 parts and water: 3 parts; Described hydrochloric acid is selected from the industrial hydrochloric acid that HCL content is 28-31%; Described polyhydric acid is lemon acid; the multi-effect additive is a mixture of fluorocarbon surfactant, potassium amine triacetate, potassium chloride and water; the active agent is demulsifier AE1910; the shrinkage agent is methacryloxy Trimethylammonium chloride; the corrosion inhibitor is a mixture of benzylpyridine and propynyl alcohol, and the mass ratio of benzylpyridine to propynyl alcohol is 5:1; the initiator is peracetic acid.

[0026] A method for preparing a polyhydric acid system suitable for reservoir deblocking ...

Embodiment 2

[0031] A polyhydric acid system suitable for deblocking acidification of reservoirs and a preparation method thereof, the polyhydric acid system comprises the following raw materials in parts by weight: hydrochloric acid: 60 parts, polyhydric acid: 12 parts, multi-effect additives: 6 parts, expansion agent: 4 parts, activator: 3 parts, initiator: 8 parts, corrosion inhibitor: 4 parts and water: 52 parts; Described hydrochloric acid is selected from the industrial hydrochloric acid that HCL content is 28-31% The polyhydric acid is phosphoric acid; the multi-effect additive is a mixture of fluorocarbon surfactant, potassium amine triacetate, potassium chloride and water; the active agent is demulsifier 1031; The swelling agent is dimethyl diallyl ammonium chloride; the corrosion inhibitor is a mixture of benzylpyridine and propynol, and the mass ratio of benzylpyridine to propynol is 5:1; the initiator is peracetic acid.

[0032] A method for preparing a polyhydric acid system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com