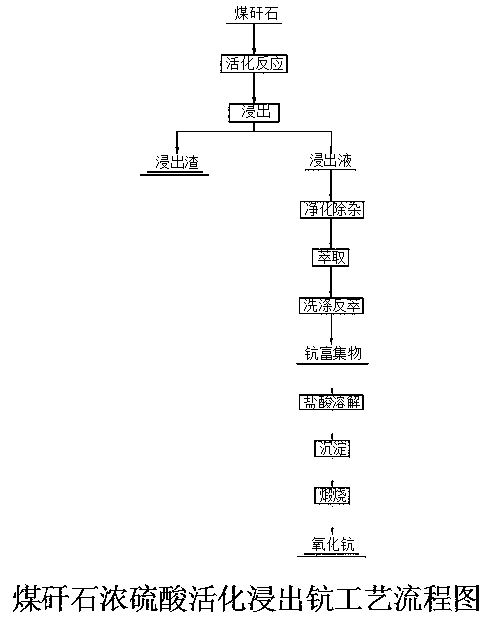

Method for extracting scandium from coal gangue through concentrated sulfuric acid activating leaching

A technology of coal gangue and concentrated sulfuric acid, which is applied in the field of rare metal metallurgy, can solve the problems of high leaching rate, large workload, and pollute the environment, and achieves the effects of simple technical process, high-efficiency leaching and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] a. Coal gangue contains scandium 50g / t, iron 6%, aluminum 26%, and titanium 6.4%. The gangue is crushed to -3mm, and it is ground with a wet ball mill until the particle size is less than 200 mesh, accounting for more than 98%;

[0023] b. Inject the pulverized coal gangue into the activation reactor, add concentrated sulfuric acid with a weight of 150% of the gangue, control the temperature at 150°C, and stir evenly for 2 hours;

[0024] c. Send the activated coal gangue to the stirring and leaching operation tank for water immersion at a liquid-solid ratio of 4:1, the operating temperature is 90°C, and the reaction time is 2h;

[0025] d. Liquid-solid separation of the ore pulp after leaching is completed, and the liquid phase is obtained as a solution containing scandium, iron, aluminum and titanium, and the solid is leaching slag containing silicon, and the leaching rate of scandium is 87.5%;

[0026] e. Heat up the solution containing scandium, titanium, iron, and ...

Embodiment 2

[0034] a. Coal gangue contains 45g / t scandium, 6.8% iron, 24.2% aluminum, and 7.4% titanium. Crush the gangue to -3mm, and grind it with a wet ball mill until the particle size is less than 200 mesh, accounting for more than 98%;

[0035] b. Inject the pulverized coal gangue into the activation reactor, add concentrated sulfuric acid with a weight of 150% of the gangue, control the temperature at 200°C, and stir evenly for 2 hours;

[0036] c. Send the activated coal gangue to the stirring and leaching operation tank for water immersion at a liquid-solid ratio of 4:1, the operating temperature is 90°C, and the reaction time is 2h;

[0037] d. The liquid-solid separation of the ore pulp after leaching is completed, and the liquid phase is obtained as a solution containing scandium, iron, aluminum and titanium, and the solid is leaching slag containing silicon, and the leaching rate of scandium is 86.1%;

[0038] e. Heat up the solution containing scandium, titanium, iron, and a...

Embodiment 3

[0046] a. Coal gangue contains 47.6g / t scandium, 5.2% iron, 25.8% aluminum, and 5.9% titanium. The gangue is crushed to -3mm and ground with a wet ball mill until the particle size is less than 200 mesh, accounting for more than 98%;

[0047] b. Inject the pulverized coal gangue into the activation reactor, add concentrated sulfuric acid with a weight of 150% of the gangue, control the temperature at 150°C, and stir evenly for 2 hours;

[0048] c. Send the activated coal gangue to the stirring and leaching operation tank for water immersion at a liquid-solid ratio of 4:1, the operating temperature is 90°C, and the reaction time is 2h;

[0049] d. The liquid-solid separation of the ore pulp after leaching is completed, and the liquid phase is obtained as a solution containing scandium, iron, aluminum and titanium, and the solid is leaching slag containing silicon, and the leaching rate of scandium is 86.8%.

[0050] e. Heat up the solution containing scandium, titanium, iron, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com