Rapid maintaining method for cement road surface

A cement pavement and fast technology, applied in the construction field, can solve the problems of large demand for consumables, complicated construction methods, and long time required for health maintenance, and achieve the effect of simplifying construction steps, fast forming, and reducing the demand for consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

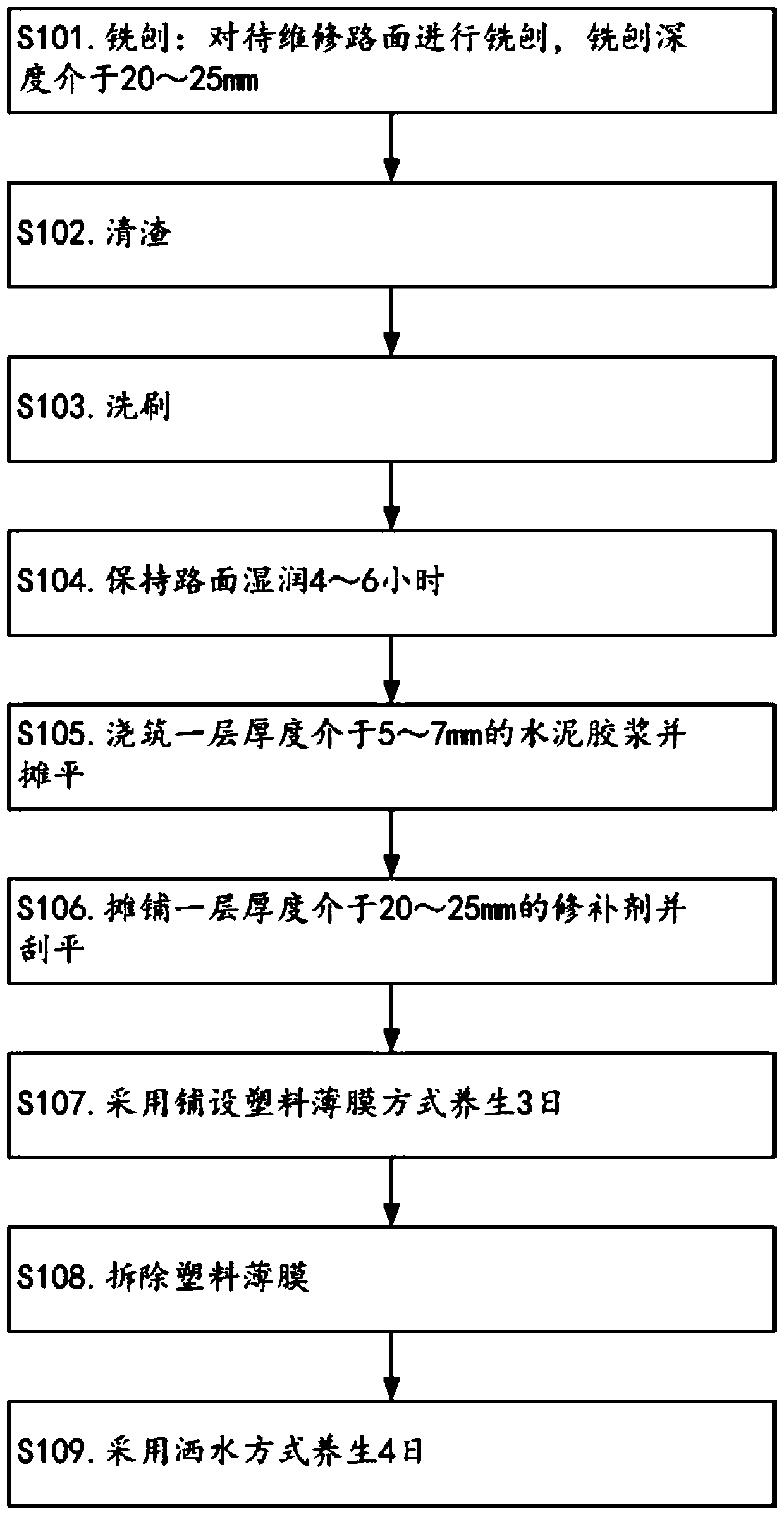

[0038] Such as figure 1 As shown, the rapid maintenance method for cement pavement provided in this embodiment includes the following steps.

[0039] S101. Milling: Milling the road surface to be repaired, the milling depth is between 20mm and 25mm.

[0040] In the step S101, the existing road surface milling machine can be used to precisely mill the road surface to be repaired (that is, the cement road surface with problems such as broken boards, cracks, exposed bones, cracks, and misalignment).

[0041] S102. Removal of slag.

[0042] In the step S102, an existing road surface slag cleaning machine may be used to perform slag cleaning on the road surface that has just been milled.

[0043] S103. Scrubbing.

[0044] In the step S103, a high-pressure water gun may be used to flush the road surface.

[0045] S104. Keep the road surface wet for 4-6 hours.

[0046] In the step S104, wet means that the moisture content of the road surface is between 12% and 15%, or the relative...

Embodiment 2

[0064] This example provides a formula for the further preferred component dosage of the cement mortar described in Example 1, that is: in parts by weight, 383-428 parts of Portland cement, 556-610 parts of graded river Sand, 38-56 parts of stone powder, 27.5-31 parts of silicon powder, 10.9-11.8 parts of fly ash, 0.3-1.6 parts of calcium formate, 0.8-5.0 parts of triisopropanolamine, 1.3-2.7 parts of α-alkenylsulfonic acid Sodium, 0.9-1.9 parts of polyvinyl alcohol, 1.5-2.4 parts of anhydrous calcium chloride and appropriate amount of water are mixed.

[0065] The technical effect of this embodiment can be directly derived based on the beneficial effect of Embodiment 1, and will not be repeated here.

Embodiment 3

[0067] This example provides a formula for the further preferred component dosage of the cement mortar described in Example 2, that is, in parts by weight, 394-420 parts of Portland cement, 570-598 parts of graded river Sand, 45-52 parts of stone powder, 28-31 parts of silicon powder, 11-11.5 parts of fly ash, 0.4-1.2 parts of calcium formate, 1.8-4.4 parts of triisopropanolamine, 1.6-2.5 parts of α-alkenyl sulfonic acid Sodium, 1.0-1.7 parts of polyvinyl alcohol, 1.7-2.3 parts of anhydrous calcium chloride and appropriate amount of water are mixed.

[0068] The technical effect of this embodiment can be directly derived based on the beneficial effect of Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com