Modular prefabricated reinforced concrete hollow pier structure and assembly method thereof

A reinforced concrete and prefabricated assembly technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., to achieve the effects of improving construction efficiency, good performance, and reducing environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

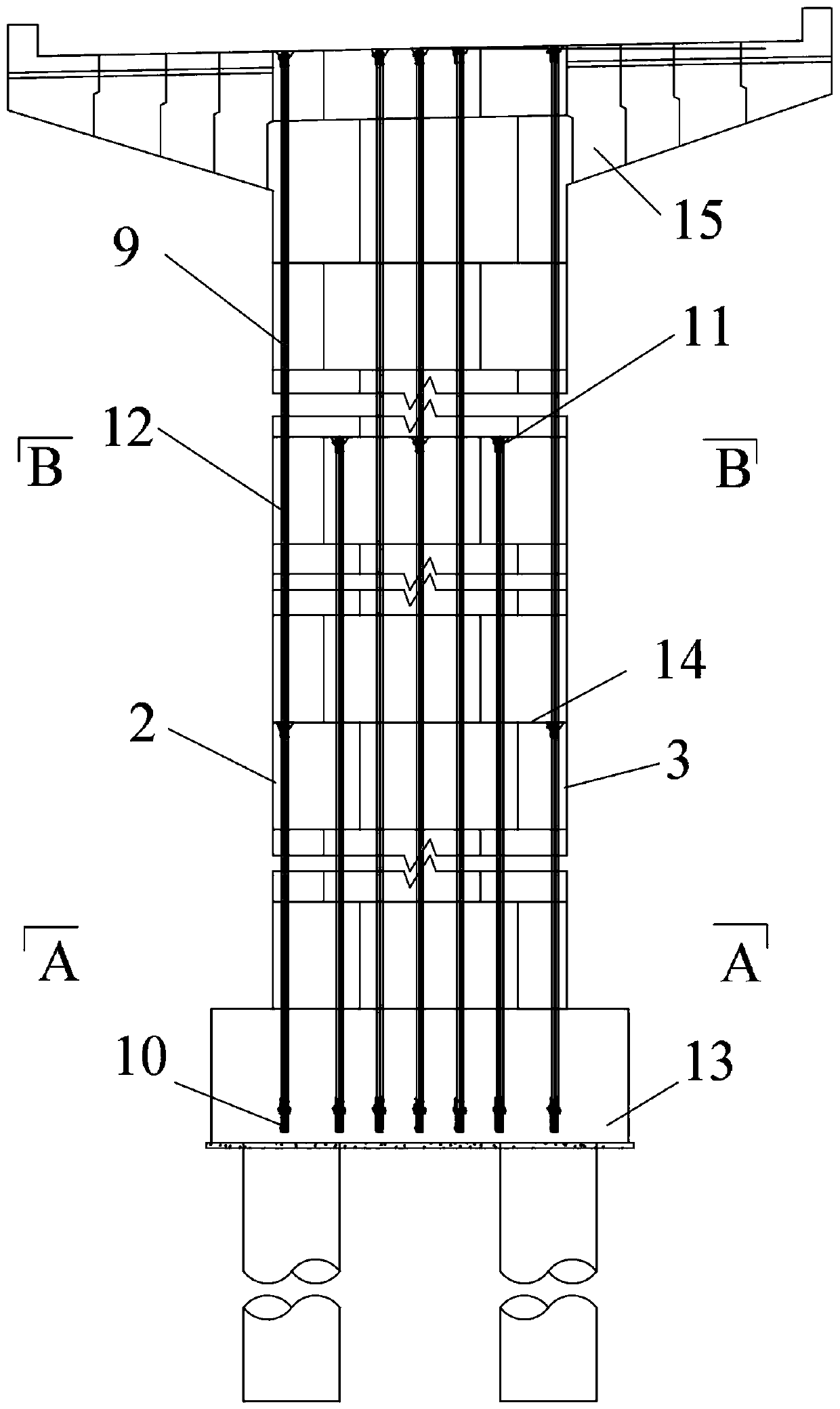

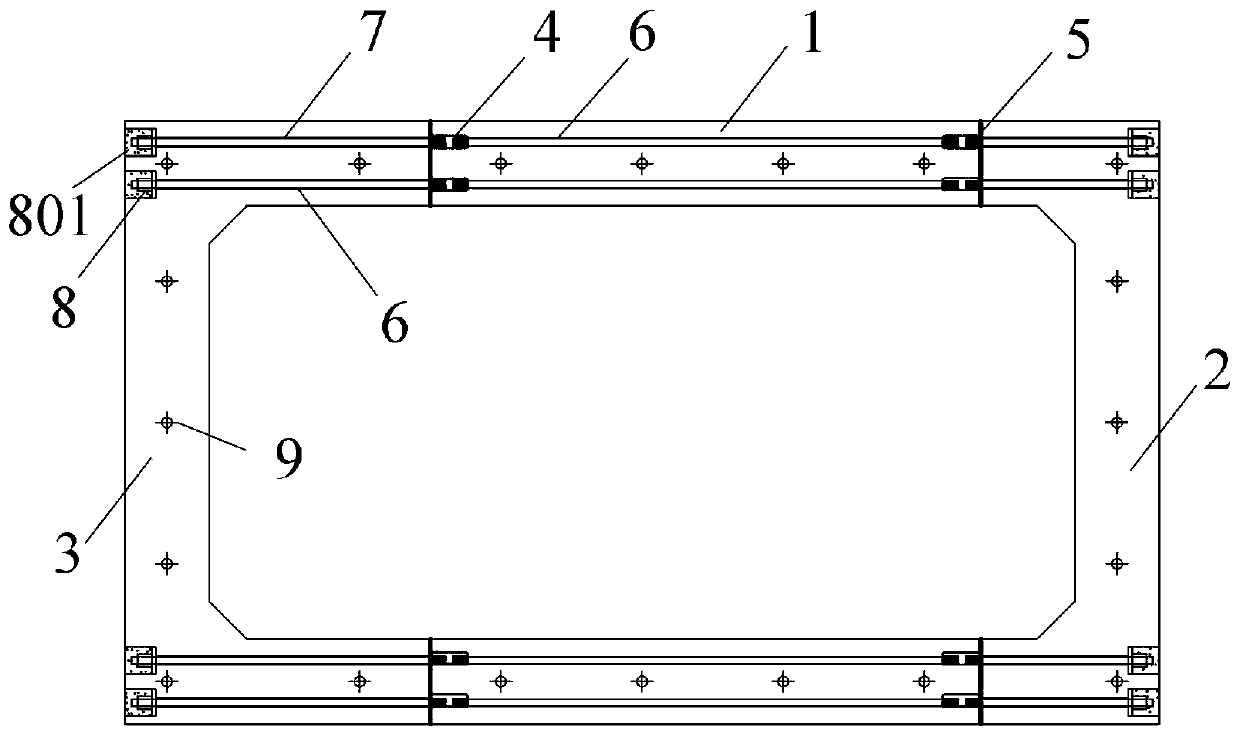

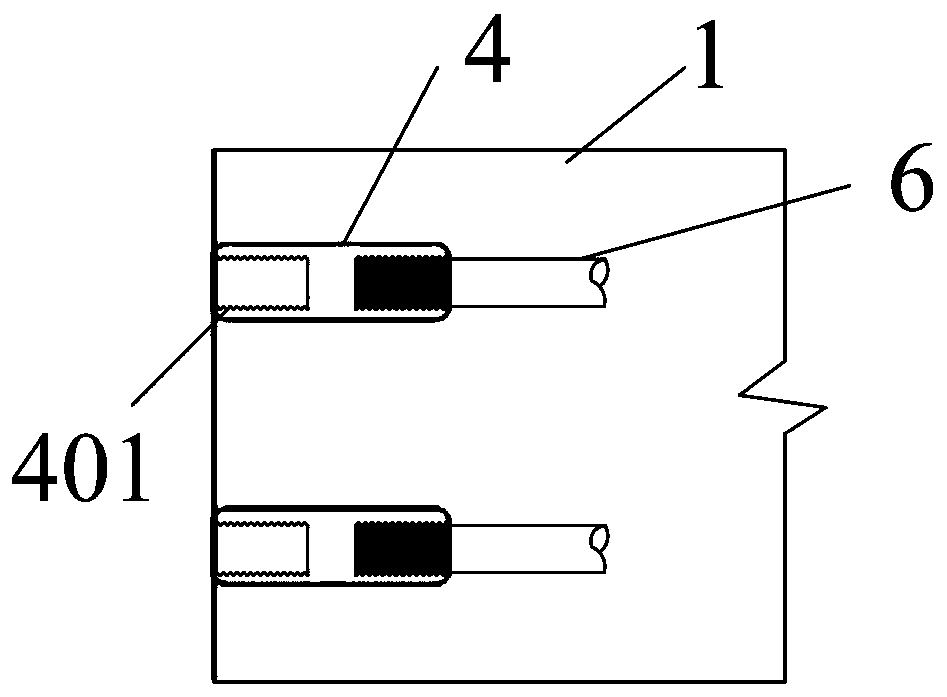

[0027] refer to figure 1 , 2 , 3. After being tightened, the fine-rolled rebar 6 and the steel bar connector 4 are pre-embedded in the middle assembly section 1 of the prefabricated component of the horizontally spliced pier body segment; The corrugated pipe channel 7 corresponding to the position of the steel bar connector 4 has a groove 8 reserved at the end for the convenience of fixing the finished rolled rebar 6 passing through the left and right asymmetric assembly segments, and is embedded in the middle of the prefabricated component for assembly The threads at both ends of the finish-rolled rebar 6 in section 1 match the thread 401 in the steel bar connector 4, and the end of the finish-rolled rebar 6 that needs to pass through the bellows channel 7 and the butt joint of the steel bar connector 4 is provided with a steel bar The connector 4 is matched with the thread 401 , and the other end is provided with a thread matched with the nut 801 . Apply 2mm epoxy adhesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com